Three tail trolleys fixed in staggered mode and arranged on arm type bucket-wheel stacker-reclaimer and material taking method thereof

A bucket-wheel stacker-reclaimer and cross-type technology, which is applied in the field of large-scale bulk material storage yard equipment, can solve the problems of high operation and maintenance costs, and achieve the effects of improving market competitiveness, reducing civil engineering costs, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

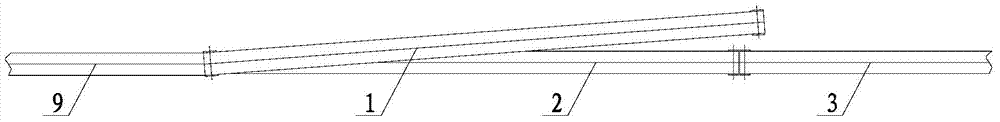

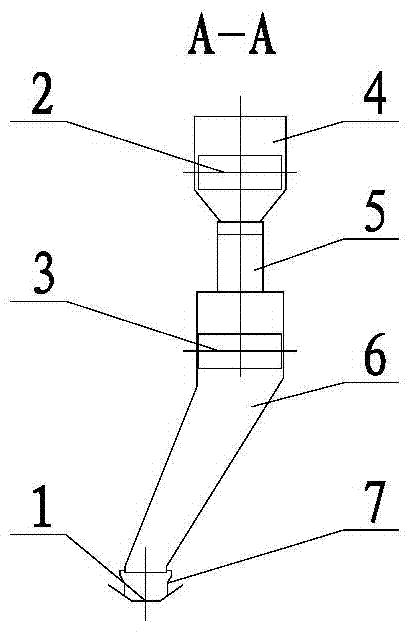

[0054] Such as Figure 1-Figure 3 As shown, an arm-type bucket-wheel stacker-reclaimer cross-type fixed three-tail car, including: tail car I1, tail car II2, tail car III3, tail car II head funnel device 4, main engine 9, tail car I head Funnel device 10, bifurcated funnel device Ⅰ5, inclined hopper device Ⅰ6, tail car Ⅲ guide chute device 7, tail car Ⅰ guide chute device 8, bifurcated hopper device Ⅱ11, cantilever hopper device 12, inclined hopper device Ⅱ13 , center funnel device 14, blanking buffer device 15 and ground conveyor belt 16;

[0055] The tail car II2 and the tail car III3 are arranged obliquely relative to the horizontal ground at an angle α, and the angle α is not greater than 16°, so that the head of the tail car II2 and the head of the tail car III3 are on the same vertical line , the head of the tail car II2 is higher than the head of the tail car III3, and the tail car I1 is arranged obliquely at an angle β with the horizontal ground, and the angle β is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com