Tool special for overhauling flotation machine and overhauling method

A technology of flotation machines and appliances, which is applied in the direction of manufacturing tools and workbenches, etc., which can solve the problems of insufficient inspection and assembly accuracy, lower operation rate, and accidental injury of workers, so as to improve enterprise labor productivity, ensure inspection quality, and improve inspection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

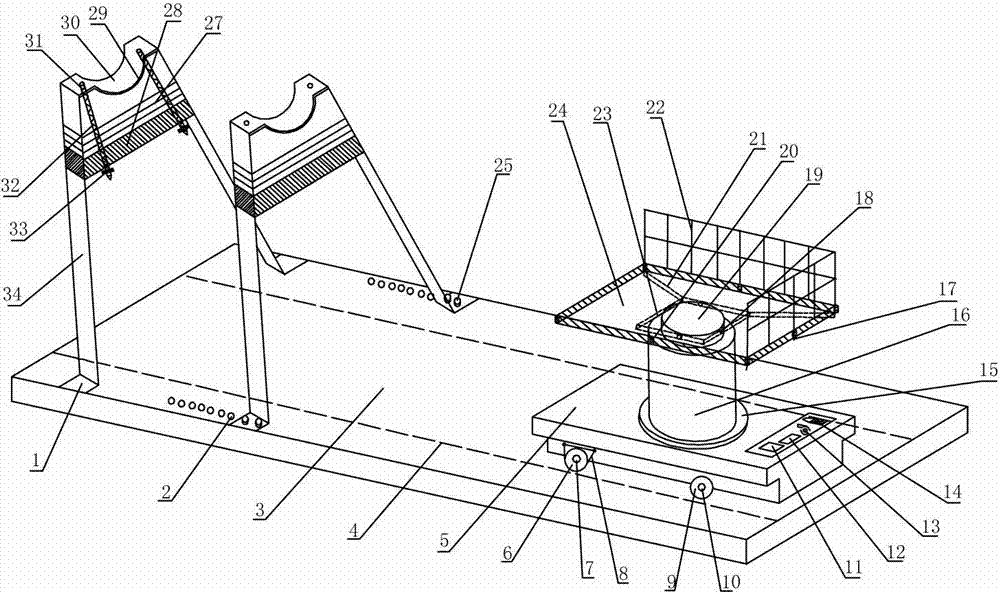

[0031] Such as figure 1 As shown, the special appliance for maintenance of flotation machine of the present invention is characterized in that it includes a machine base platform, a fixed support bracket arranged on the machine base platform, a movable support bracket, a mobile rail car, a hydraulic lifting system, and an inspection bracket. plate installations and safety rail installations,

[0032] The base platform is composed of a base platform platen 3 and a horizontal groove track 4. There are two horizontal groove rails 4, which are longitudinally symmetrically fixed on both sides of the bottom of the base platform platen 3. There are two rows of reserved holes 2 for screw fastening at the edge of both sides of the surface of the seat platform platen 3 .

[0033]Both the fixed support bracket and the movable support bracket are composed of side columns 34, bracket feet 1, transverse connecting plates 28, adjusting gaskets 27, full-thread long rods 32 and trapezoidal br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com