Rotating device of grinding main engine

A technology of a rotating device and a main engine, which is applied to the grinding drive device, the parts of the grinding machine tool, the grinding machine, etc., can solve the problems of difficulty in changing the relative angle, inconvenient production, etc., and achieve the effect of improving the grinding capacity and facilitating the production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

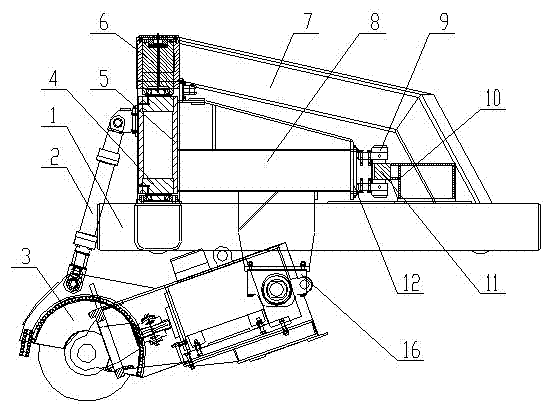

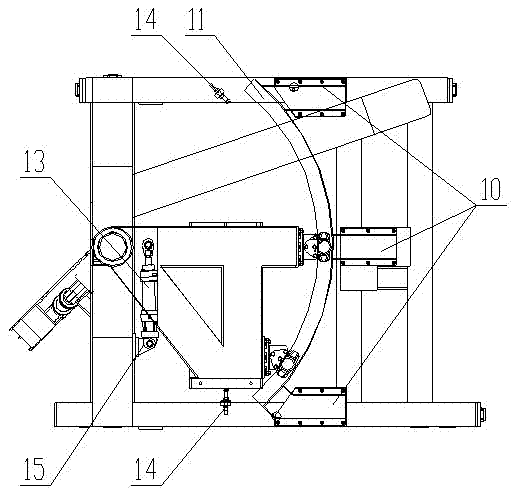

[0029] see figure 1 , figure 2 , the present invention is a kind of rotating device for grinding main engine, which includes a fixed frame 1, a fixed frame support beam 7 is arranged on the fixed frame 1, and a rotary column 5 is arranged between the fixed frame 1 and the fixed frame support beam 7, so that The rotary column 5 is internally provided with a shaft head 4 positioned by bearings at both ends and a pre-tightening device 6 fixed by the upper flange. The rotary column 5 can rotate around the center, and a sliding seat 8 is provided on the right side of the rotary column 5. The left side of the slewing column 5 is provided with a lifting hydraulic cylinder 2, the bottom of the sliding seat 8 is provided with a bearing seat bearing structure 16, and the bottom of the fixed frame 1 is provided with a grinding host 3, and the head of the grinding host 3 is connected to the The piston rod ends of the lifting hydraulic cylinder 2 are connected, the tail of the grinding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com