Vertical wet-process ball mill

A wet ball mill, vertical technology, applied in the field of vertical wet ball mill, can solve the problems of increased processing capacity and unbearable equipment, so as to reduce equipment energy consumption, reduce grinding production cost, and improve grinding production capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0035] Unless otherwise specified, the technical means used in the embodiments are conventional means well known to those skilled in the art.

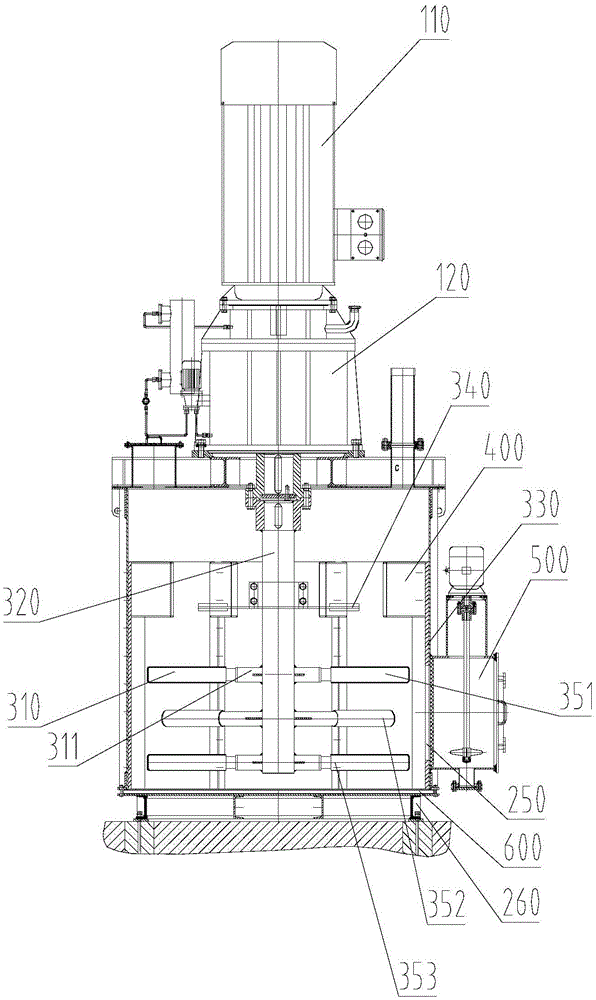

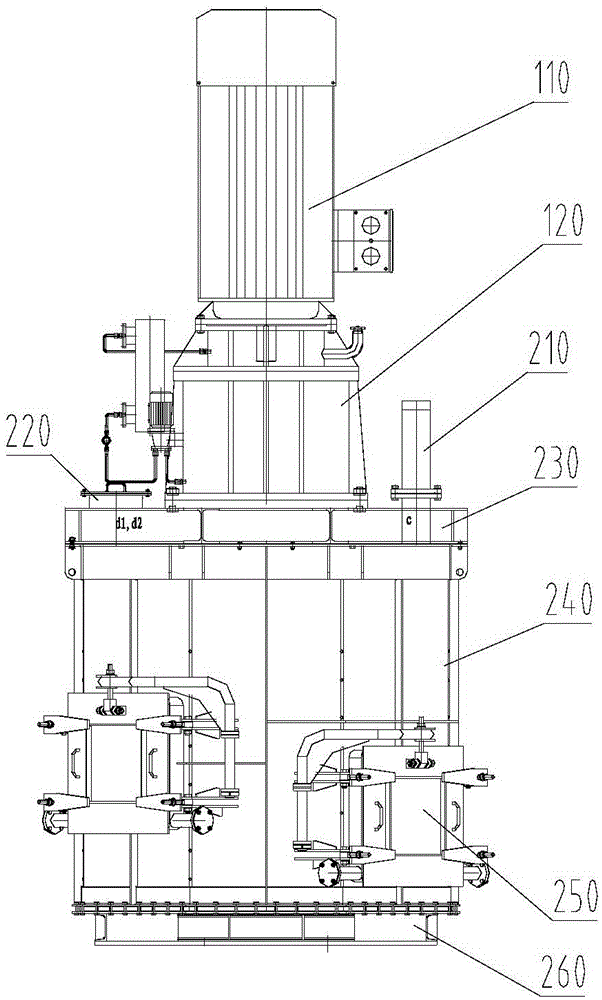

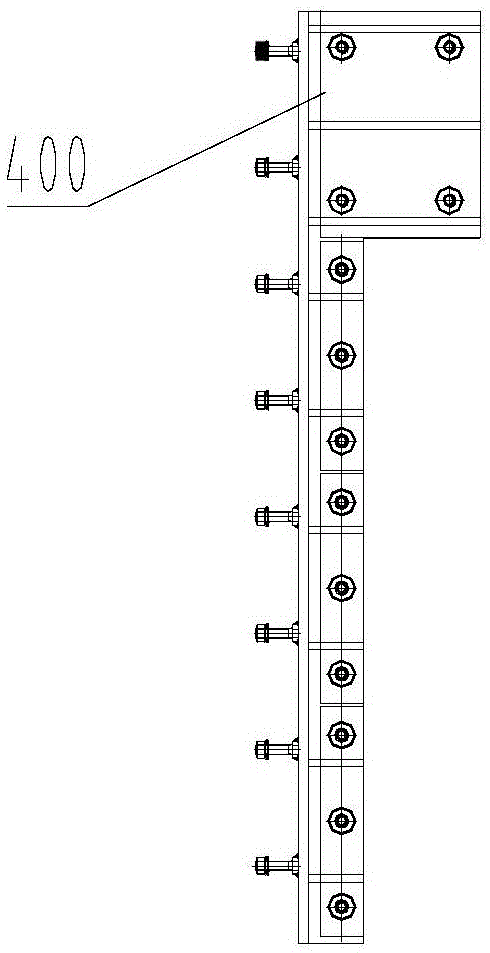

[0036] see figure 1 , In one embodiment, the vertical ball mill provided by the present invention includes a motor 110 , a reducer 120 , a cylinder 240 and a base 260 . The bottom of the barrel 240 is installed on the base 260 . At least one slurry outlet 250 is opened on the lower part of the side wall of the cylinder body 240 . The top surface of the cylinder body 240 is open, and the cylinder cover 230 is arranged on it. A feed port 220 and an observation port 210 are spaced apart on the cylinder cover 230 . see figure 2 , the motor 110 drives the agitator extending into the barrel 240 . The agitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com