Sharpening blade of welding electrode and grinding method

A technology for welding electrodes and blades, applied in the field of machinery, can solve the problems of reduced cutting ability and reduced service life of grinding blades, and achieve the effects of reducing friction, ensuring grinding quality, and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment discloses a grinding blade that can simultaneously cut and recover the welding surfaces of two welding electrodes that are damaged to different degrees up and down. Through the grinding blade, the welding surfaces of the upper and lower welding electrodes can be cut and trimmed respectively at the same time, thereby grinding an electrode cap with specific geometric characteristics on the welding surface, and also recovering an integral welding electrode with specific geometric characteristics on the welding surface. The dressing of the welding electrode can be repeated as many times as necessary until the welding surface can no longer support dressing due to material loss.

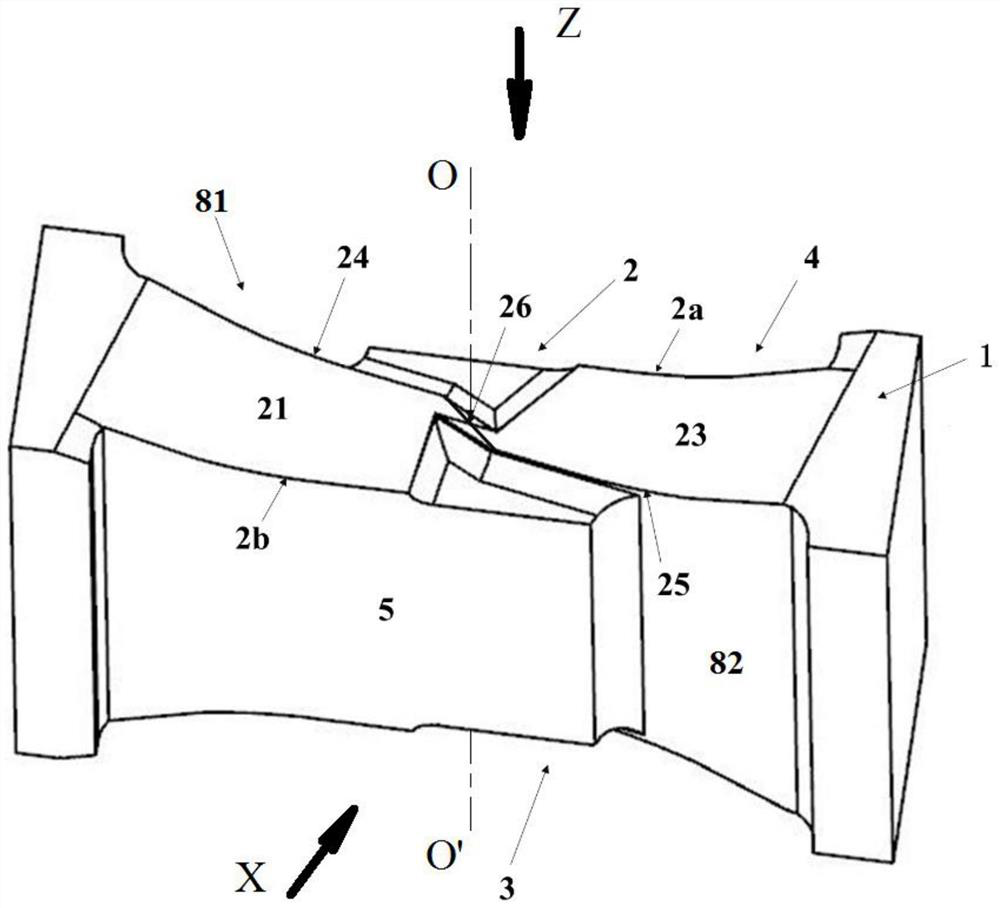

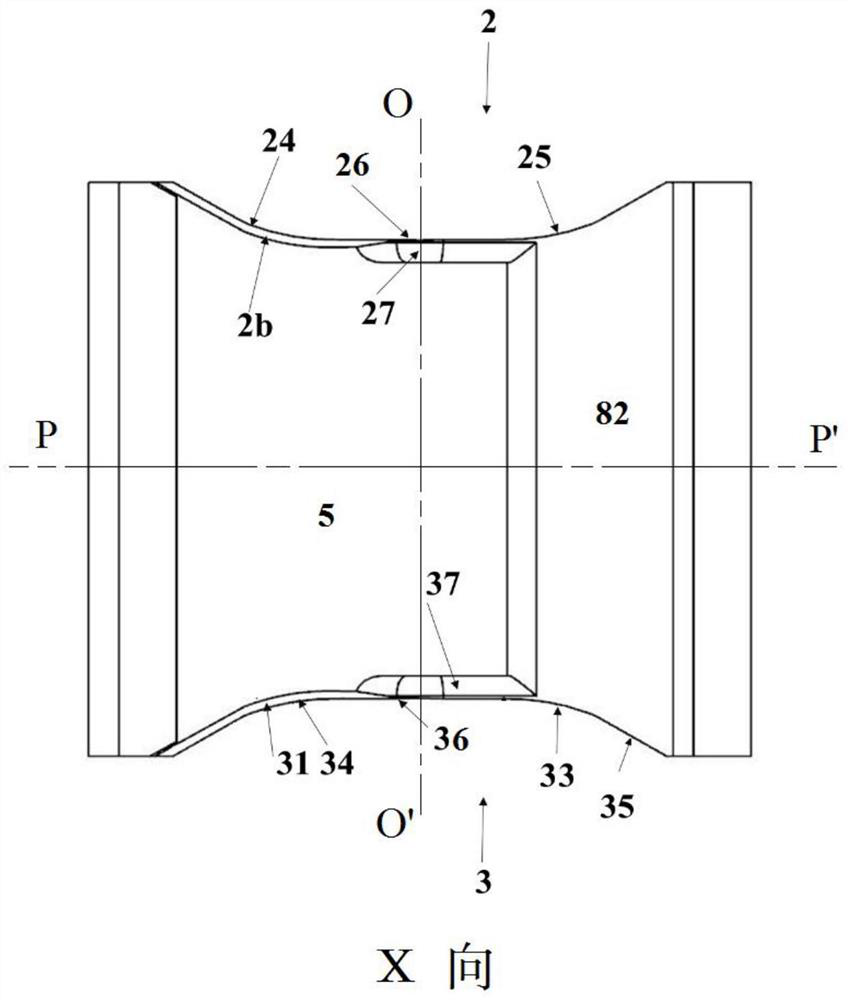

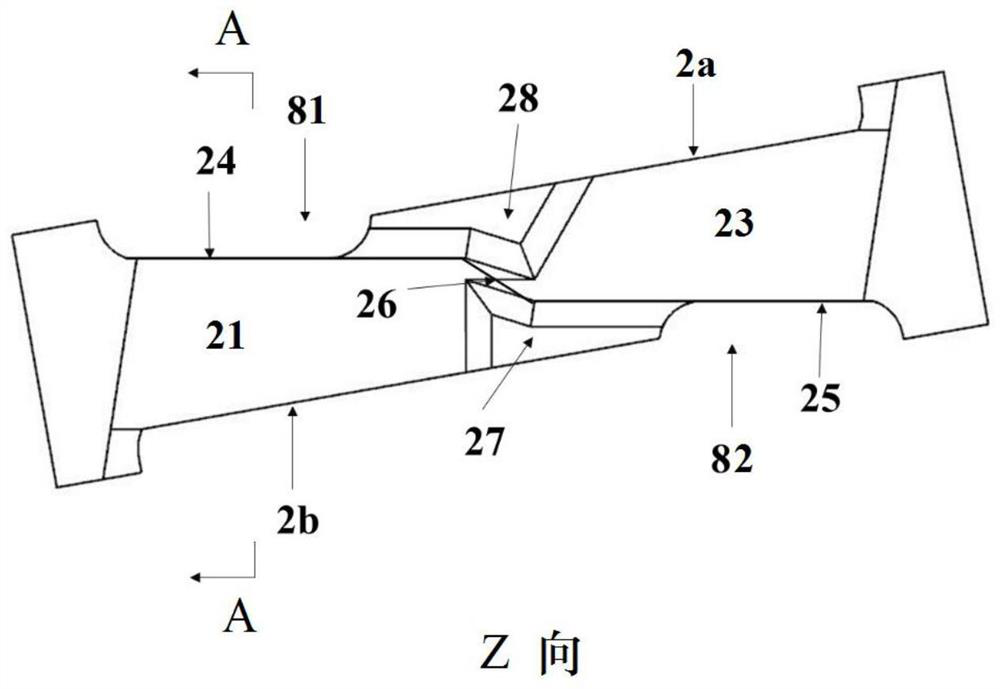

[0057] Such as figure 1 , figure 2 and image 3 As shown, the grinding blade is an integral structure, which is provided with an I-shaped support type main body 1; the support type main body 1 is composed of a cutting part in the middle and mounting parts at both ends, and the cut...

Embodiment 2

[0075] This embodiment can meet the requirement of grinding the upper welding electrode 91 and the lower welding electrode 92 with different welding surface shapes. The structure of the second embodiment is basically the same as that of the first embodiment, except that the first cutting groove 2 and the second cutting groove 3 are no longer arranged symmetrically with respect to the central axis of rotation OO'.

[0076] In this embodiment, the structure of the first cutting groove 2 is similar to that of the second cutting groove 3, but the size and shape of the third cutting edge 34, the fourth cutting edge 35 and the second chisel edge 36 are different from the first cutting edge 34. The first cutting edge 24 , the second cutting edge 25 and the first chisel edge 26 are adjusted to different corresponding shapes and sizes according to the operation requirements.

[0077] The state of repairing the welding surface of the upper welding electrode 91 and the lower welding elec...

Embodiment 3

[0079] The structure of the third embodiment is basically the same as that of the first embodiment, except that a forming groove is provided on the cutting edge and a chip breaker is provided on the cutting surface.

[0080] Please refer to Figure 10 , Figure 11 and Figure 12 , the illustrated grinding blade is provided with a pedestal-type main body, which is composed of a cutting part in the middle and mounting parts at both ends, and has a central axis of rotation OO' along the vertical direction in the center. One side elevation of the cutting portion is provided with a first rake surface 81 and a second chip removal surface 4, and the other side elevation is provided with a second rake surface 82 and a first chip removal surface 5, and the cutting portion includes There are first cutting groove 2 and second cutting groove 3 opposite up and down.

[0081] The first cutting groove 2 includes a first cutting surface 21, a second cutting surface 23 and two third cutting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com