Pressure controllable abrasive belt tool system for grinding and polishing blades

A tool, grinding and polishing technology, applied in the field of blade grinding and polishing tools, can solve the problems of poor surface quality, low efficiency, uneven grinding and polishing of blade curved surface, etc., and achieve the effect of novel structure, high processing quality and uniform grinding and polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

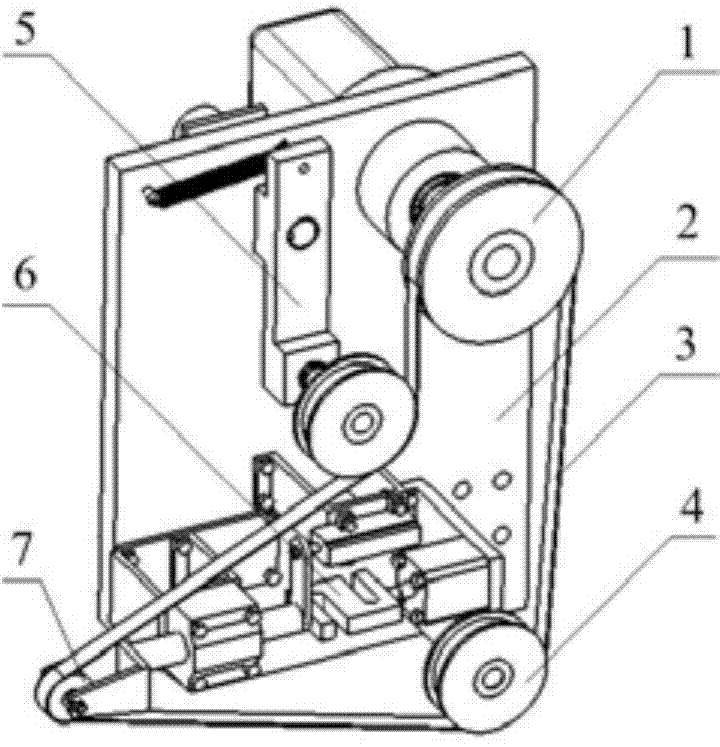

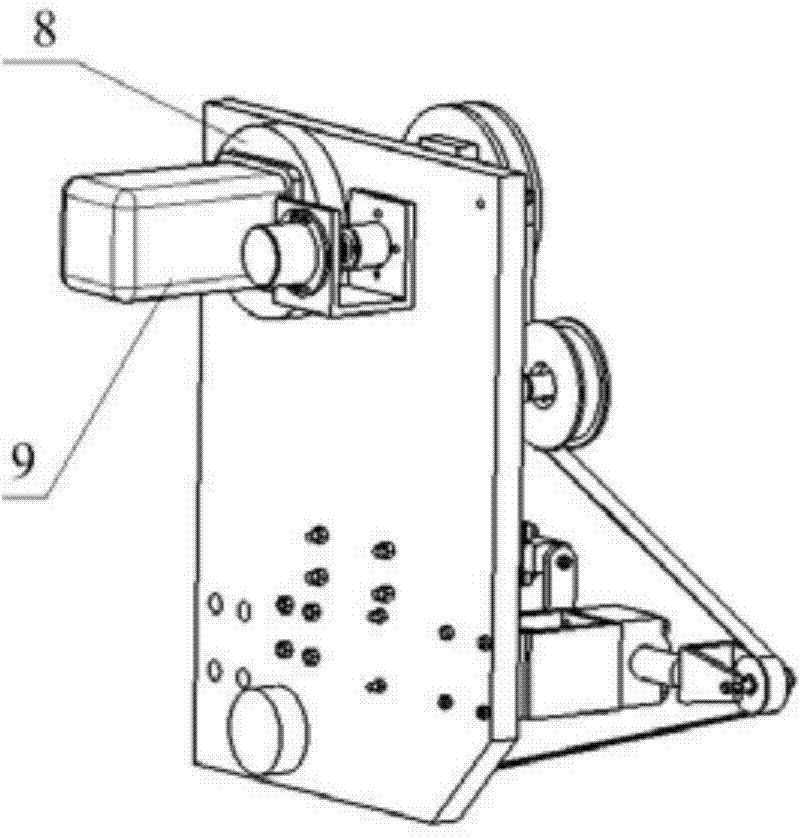

[0016] The driving wheel 1, the idler wheel 4, the tensioning mechanism 5, and the grinding and polishing pressure control mechanism 6 are installed on the tool plate 2, the servo motor 9 is connected with the tool plate 2 through the motor support 8, the driving wheel 1 is connected with the servo motor 9, and the contact The wheel 7 adopts the structure of sticking rubber material on the surface of the main body of the metal hub, the abrasive belt 3 is externally connected with the driving wheel 1, the idler 4 and the contact wheel 7, and the tensioning mechanism 5 is tensioned and connected with the abrasive belt 3;

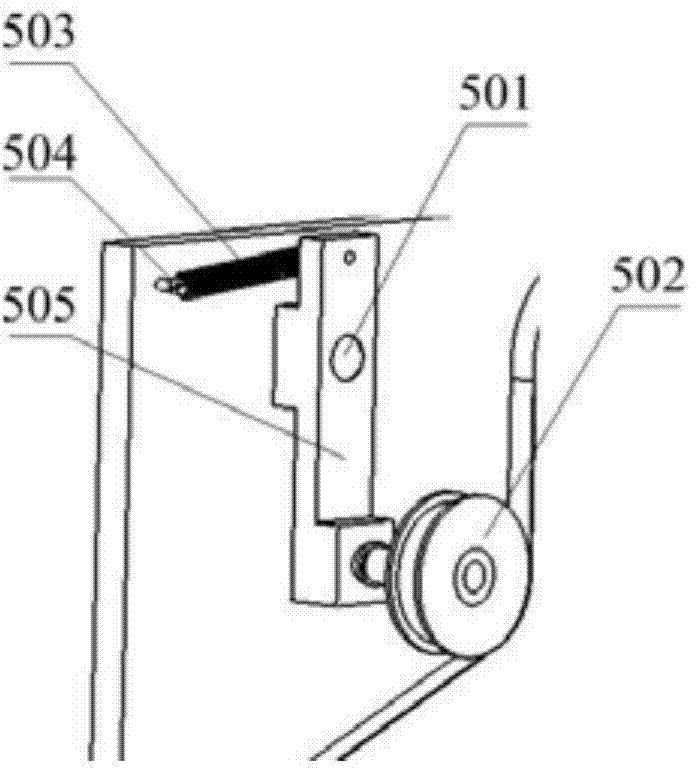

[0017] The structure of the tensioning mechanism is that the tensioning arm shaft 501 is installed on the tool plate 2 through a bearing, the tensioning arm 505 is fixedly connected with the tensioning arm shaft 501, the spring 503 is installed on the tool plate 2 through a pin 504, and the tensioning arm 505 is fixedly connected with the tensioning arm shaft 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com