Steel rail induction butt welding and heat treatment method

A heat treatment method and butt welding technology, applied in heat treatment furnaces, heat treatment equipment, rails, etc., can solve problems such as unstable quality of rail welded joints, low rail construction organization efficiency, and increased construction site requirements, so as to reduce the impact of human factors. , The effect of reducing labor intensity and reducing equipment and site requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

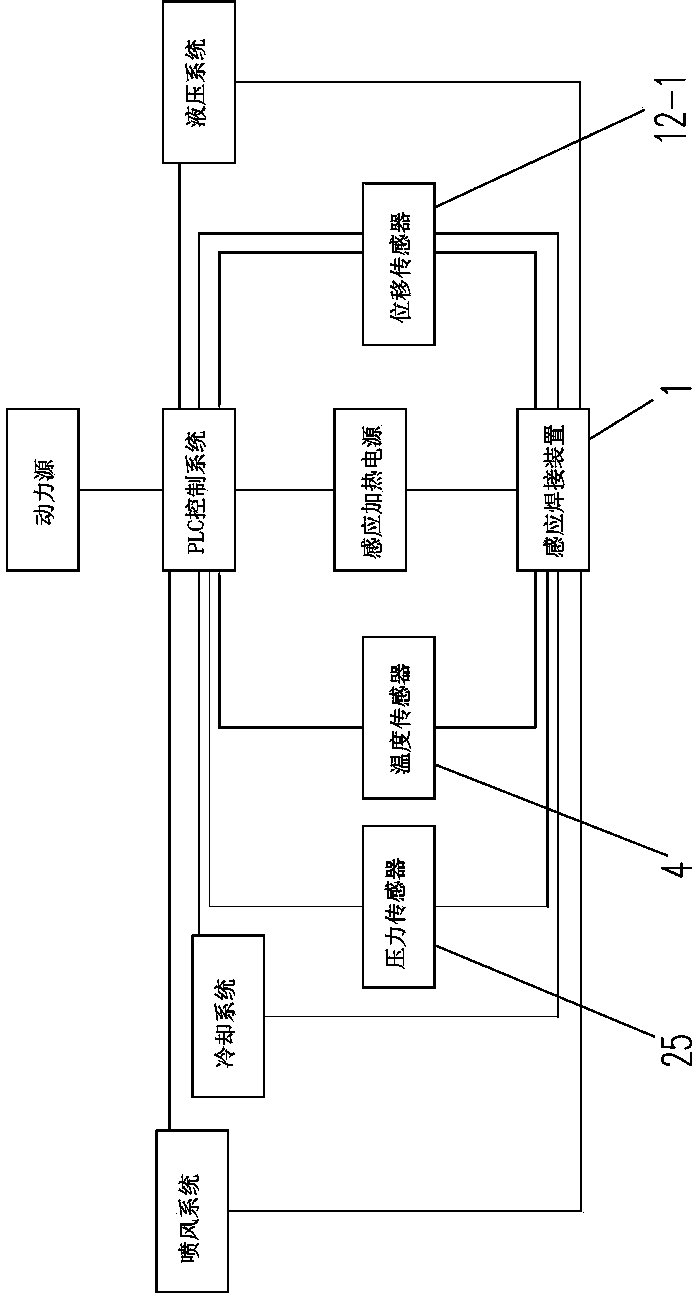

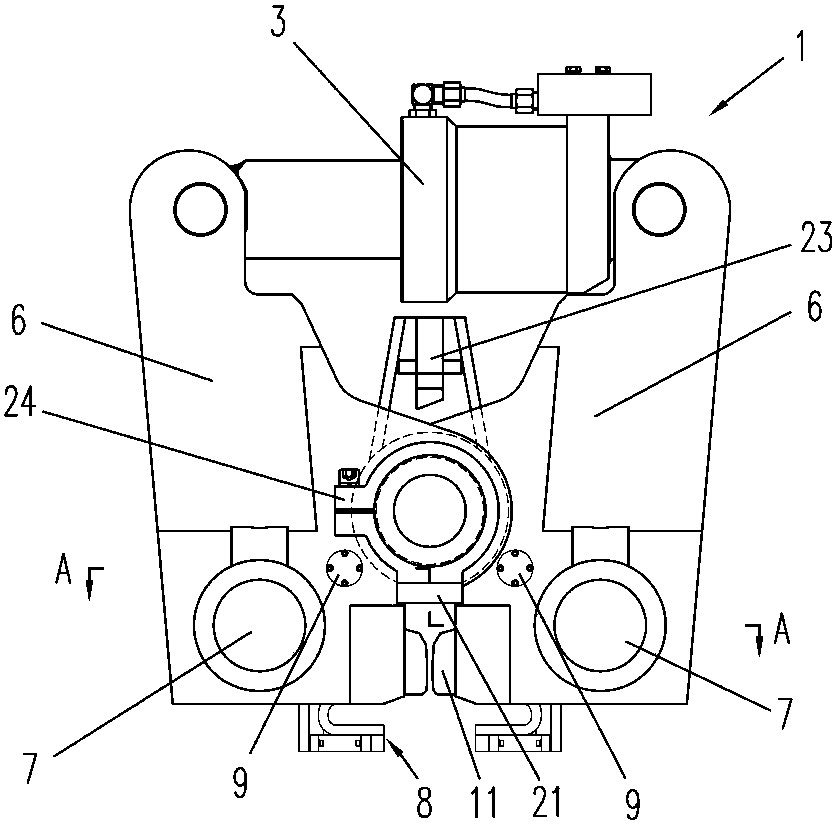

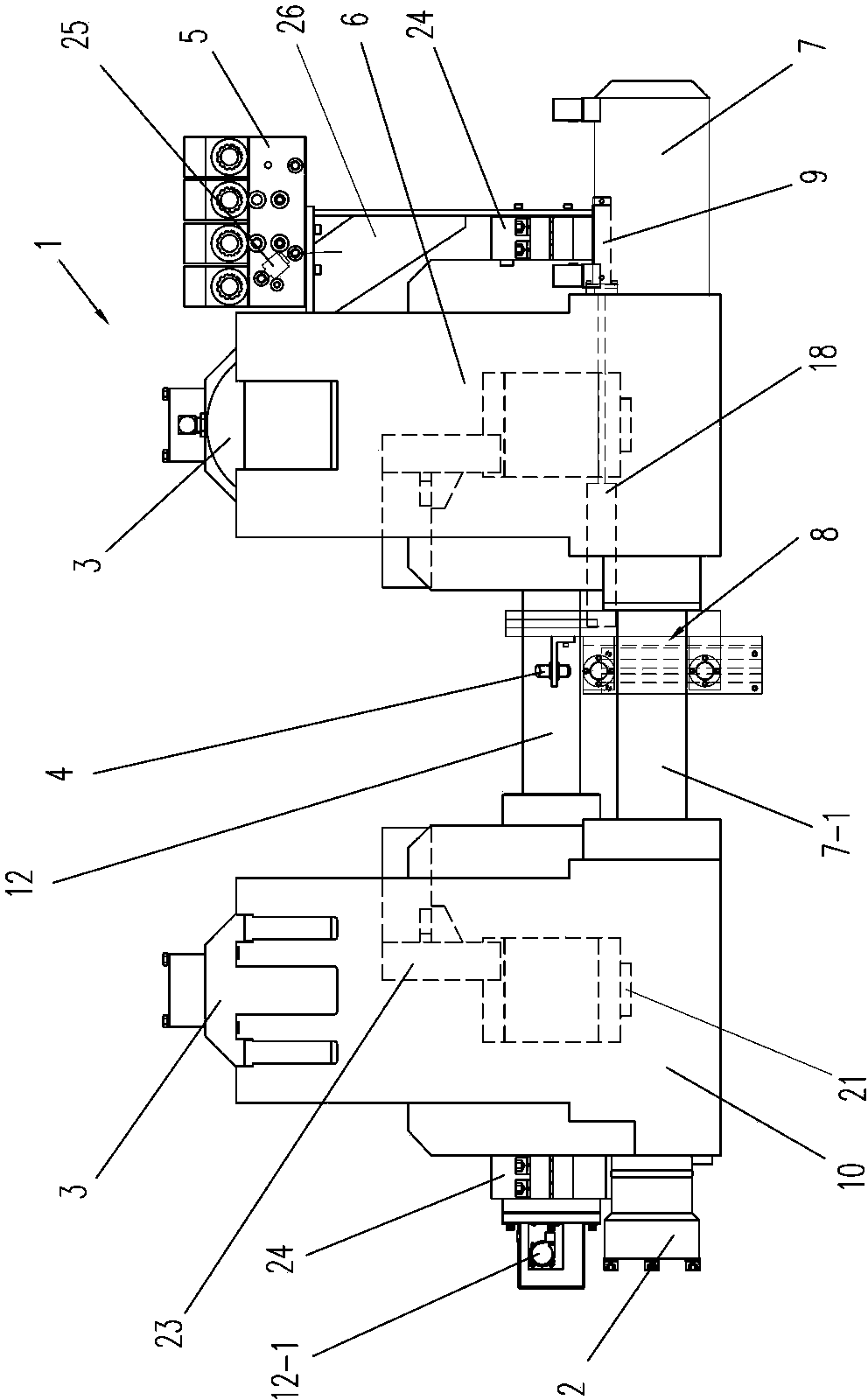

[0042] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, and 13, a kind of rail induction butt welding and heat treatment method of the present invention comprises the following steps:

[0043] a. The two rails 20 are positioned through the positioning piece 21 attached to the lower part of the central axis 12 of the induction welding device 1; the induction welding device 1, hydraulic system, cooling system, induction heating power supply and blowing system are controlled by the PLC control system to execute subsequent actions;

[0044] b. The two clamping oil cylinders 3 on the induction welding device 1 drive the two groups of clamp bodies 10 and 6 to rotate around the central axis 12 respectively, so that the jaws 11 at the bottom of the two groups of clamp bodies 10 and 6 respectively hold the two steel rails 20 Clamp and center;

[0045] c. The upsetting oil cylinder 7 on the induction welding device 1 applies an initial upsetting force to make the end faces of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com