Cold-rolled steel strip rolling method

A technology for cold-rolling steel strips and strips, which is applied in metal rolling, metal rolling, and tool manufacturing. It can solve problems such as complex equipment, increased deflection of work rolls, and difficulty in reducing the diameter of work rolls to achieve increased thickness. The effect of controlling precision, improving board surface cleanliness, and eliminating emulsion entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

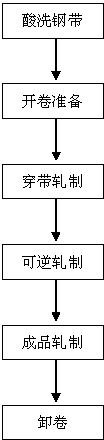

[0031] Such as figure 1 Shown, the cold-rolled strip rolling method comprises the steps:

[0032] (1) Preparation for opening the book

[0033] The pickled carbon steel strip is placed on the material support frame, and the strip coil is transported to the reel of the uncoiler by the feeding trolley. After the reel is tightened, the scraper of the straightener rises to cut off the strap Hold the tape head, lower the pressure roller of the uncoiler and run it jog, first send the tape head to the pinch roller, press the upper pinch roller to send the tape head to the five-roller straightening roller, and the upper straightening roller will straighten the tape head and send it to the hydraulic pressure Cut off the irregular lead and complete the preparation for uncoiling.

[0034] The uncoiler is a cantilever floating structure, and the reel is a pyrami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com