Array substrate and preparing method thereof, display device and preparing method thereof

A technology for array substrates and display devices, applied in the fields of array substrates and their preparation, display devices and their preparations, can solve problems such as gate drive circuit damage, abnormal screen display, and failure to work normally, so as to improve reliability and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

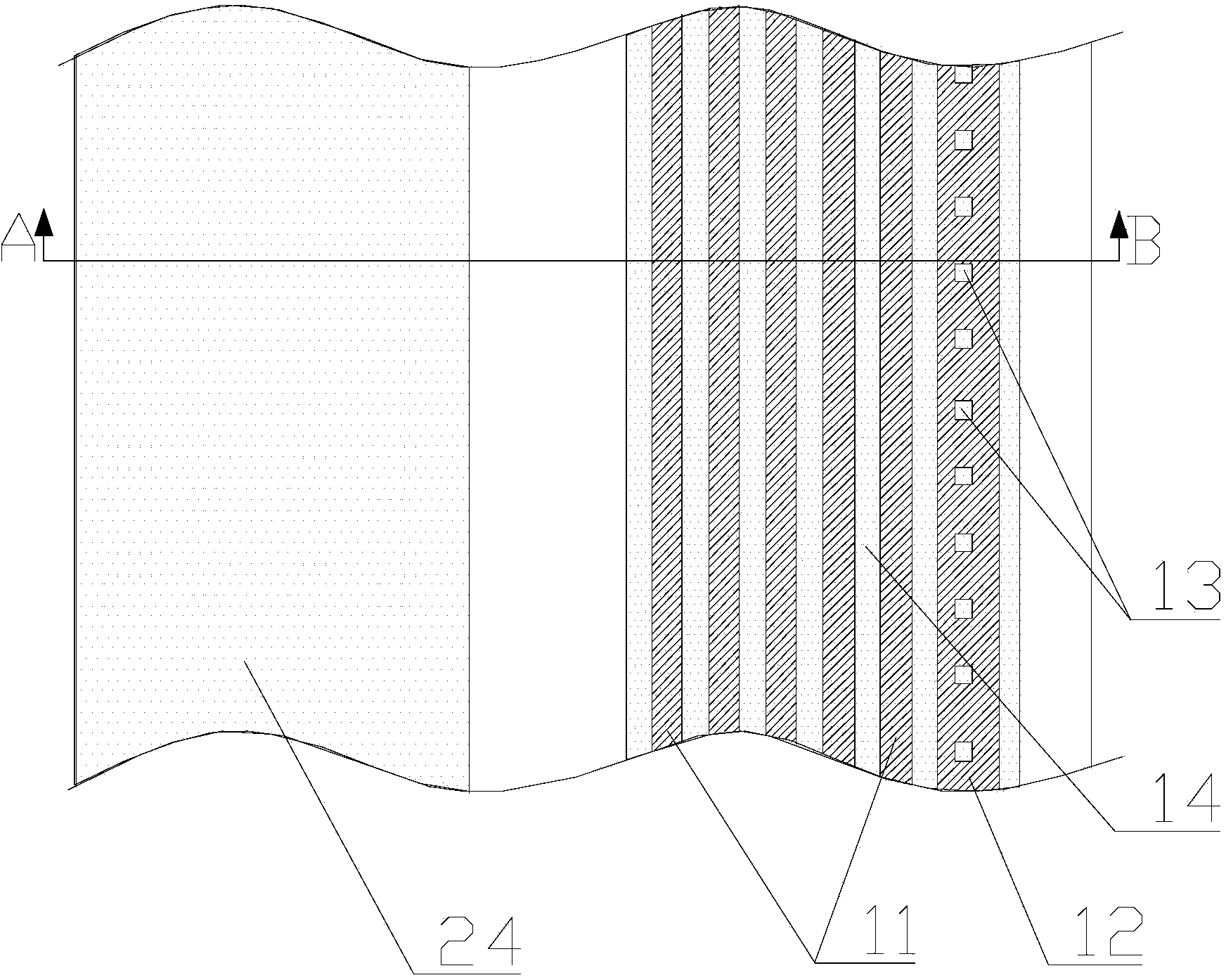

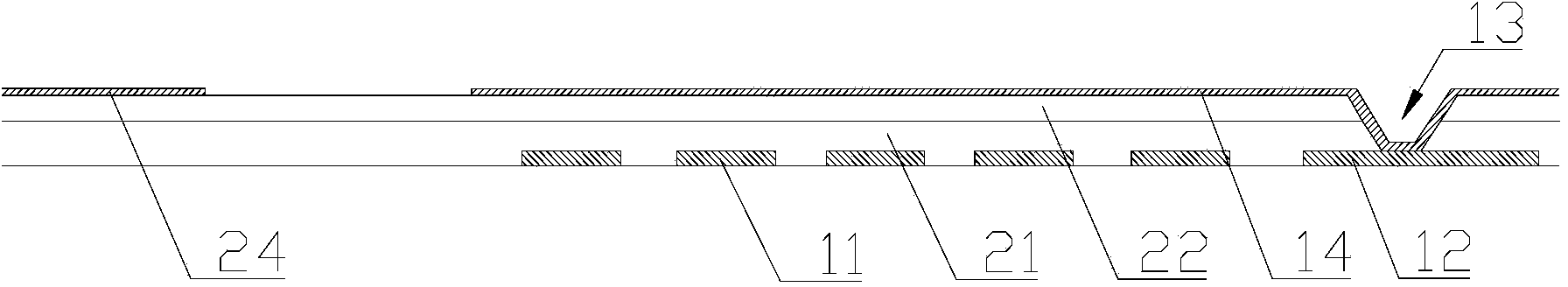

[0060] In this embodiment, the array substrate mainly includes a base substrate, which can be a glass substrate, a quartz substrate, or other flexible substrates, etc., and several pixel units are arranged on the base substrate, and each pixel unit usually includes a TFT, and the TFT Generally, it includes a source, a gate, and a drain. Each pixel unit may also include a pixel electrode, a common electrode, and a touch electrode. In addition, a touch electrode may also be provided on the array substrate. The TFT of each pixel unit needs to be connected with a corresponding driving circuit for providing driving signals for each TFT.

[0061] The above-mentioned drive circuits mainly include drive circuits such as gate drive circuits, source drive circuits, common electrode drive circuits, and touch drive circuits. Various drive circuits can be manufactured using the process of external chips, and can also be partially or completely arranged on the array substrate. Therefore, th...

Embodiment 2

[0070] The present invention also provides a display device using any one of the above-mentioned array substrates, the display device mainly comprising any one of the above-mentioned array substrates and a cell-aligning substrate disposed opposite to the array substrate.

[0071] The box-to-box substrate can be different depending on the type of display device; for example, in a liquid crystal display device, the box-to-box substrate can be a color filter substrate, while an OLED (Organic Light Emitting Diode, organic light-emitting diode) In a display device with a level tube), the pair of cell substrates may be a packaging substrate or the like.

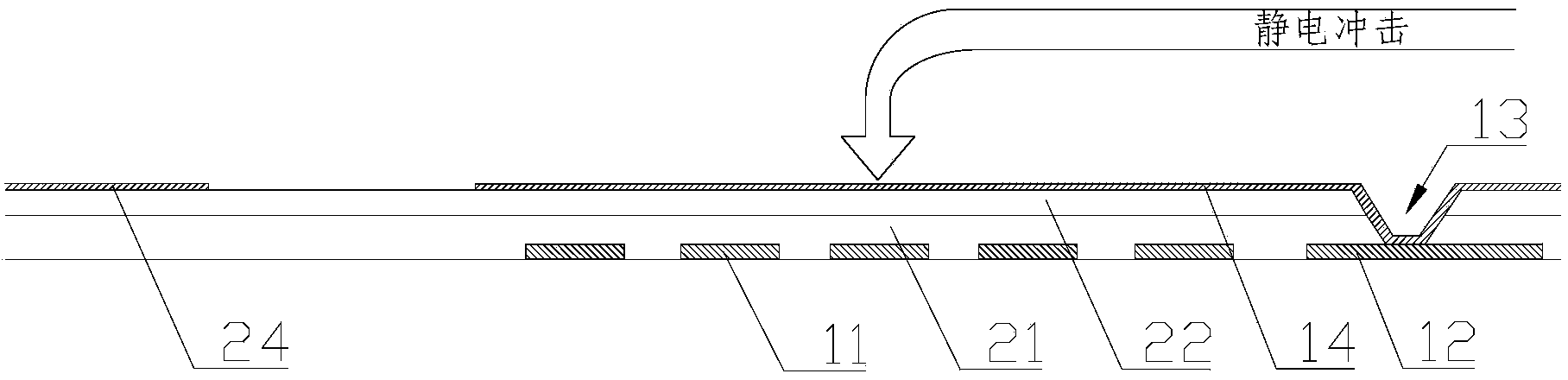

[0072] Since the array substrate used in the display device is provided with a grounding structure including grounding leads and a first electrostatic protection layer, the grounding structure can be used to effectively protect the drive circuit provided on the array substrate from electrostatic shocks, thereby avoiding electrostati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com