High-temperature early warning system of coupler

An early warning system and coupling technology, applied in the field of early warning systems and transmission machinery early warning systems, can solve problems such as bearing lubrication deterioration, oil waste, coupling structural deformation, etc., to prevent excessive oil temperature and avoid oil waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with accompanying drawing.

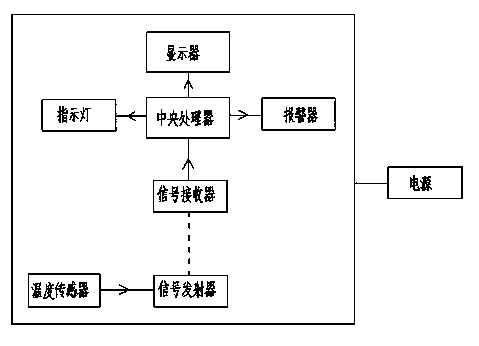

[0008] Such as figure 1 As shown, a coupler high temperature early warning system includes a temperature sensor, a signal transmitter, a signal receiver, a central processing unit, an indicator light, an alarm, a display, and a power supply. The temperature sensor and the signal transmitter are installed on the coupler On the casing, the temperature sensor, the signal transmitter, and the power supply are connected in sequence; the signal transmitter is matched with the signal receiver, and the two are connected through wireless; 1. Display connection, the signal receiver, central processing unit, indicator light, alarm, and display are respectively connected to the power supply.

[0009] Preferably, the display is an LED display, and the display effect is better.

[0010] Preferably, the indicator light is a diode emitting red light and green light, which can emit differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com