A dual-chamber electrically actuated valveless micropump

A micro-pump and actuation technology, applied in the direction of pumps, machines/engines, liquid variable capacity machines, etc., can solve the problems of small initial volume and static volume, low working efficiency, large compression ratio, etc., and achieve high flow and pressure. , simple structure, the effect of output flow and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

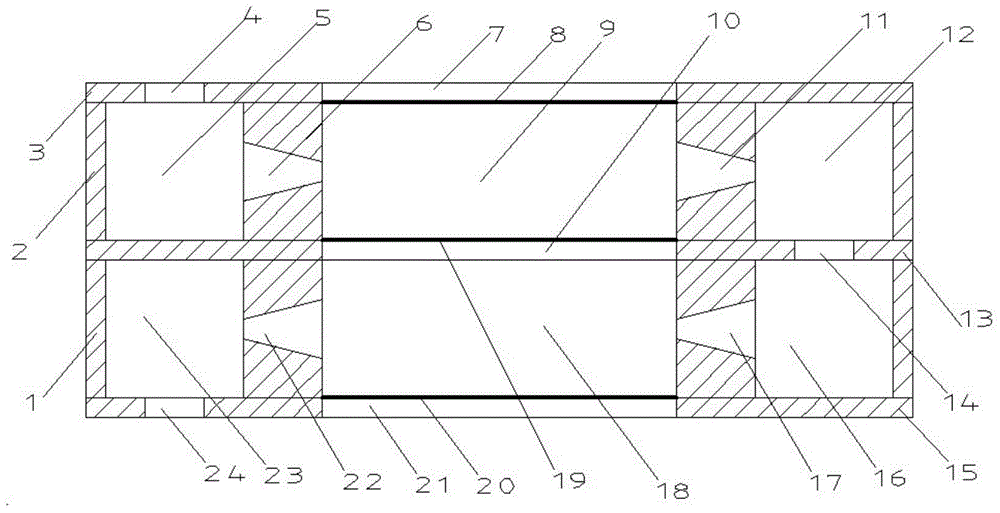

[0028] Such as figure 1As shown, the present invention includes two parts, the driving membrane and the micropump. The micropump is divided into two parts, a pump body and a pump cover, and the pump body is divided into an upper pump body 2 and a lower pump body 1 . Described pump cover is divided into upper pump cover 3, middle pump cover 13 and lower pump cover 15. The upper pump body 2 is located between the upper pump cover 3 and the middle pump cover 13, and the lower pump body 1 is located between the middle pump cover 13 and the lower pump cover 15, and the pump cover and the pump body overlap at intervals to form a micro pump. The upper pump cover 3 has a large hole 7 in the middle position, the left end of the large hole 7 is an outlet small hole 4, the middle pump cover 13 has a large hole 10, the right end of the large hole 10 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com