Methods and equipment for recovering waste diachylon by wet method and manufacturing electrode active material of high performance lead acid battery by wet method

A technology for waste lead-acid batteries and electrode active materials, which is applied to the wet recovery and reuse of lead or lead compounds, and the field of lead paste for waste lead-acid batteries, which can solve the problems of limited economic and social benefits, insufficient supply of waste lead-acid batteries, poor profitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

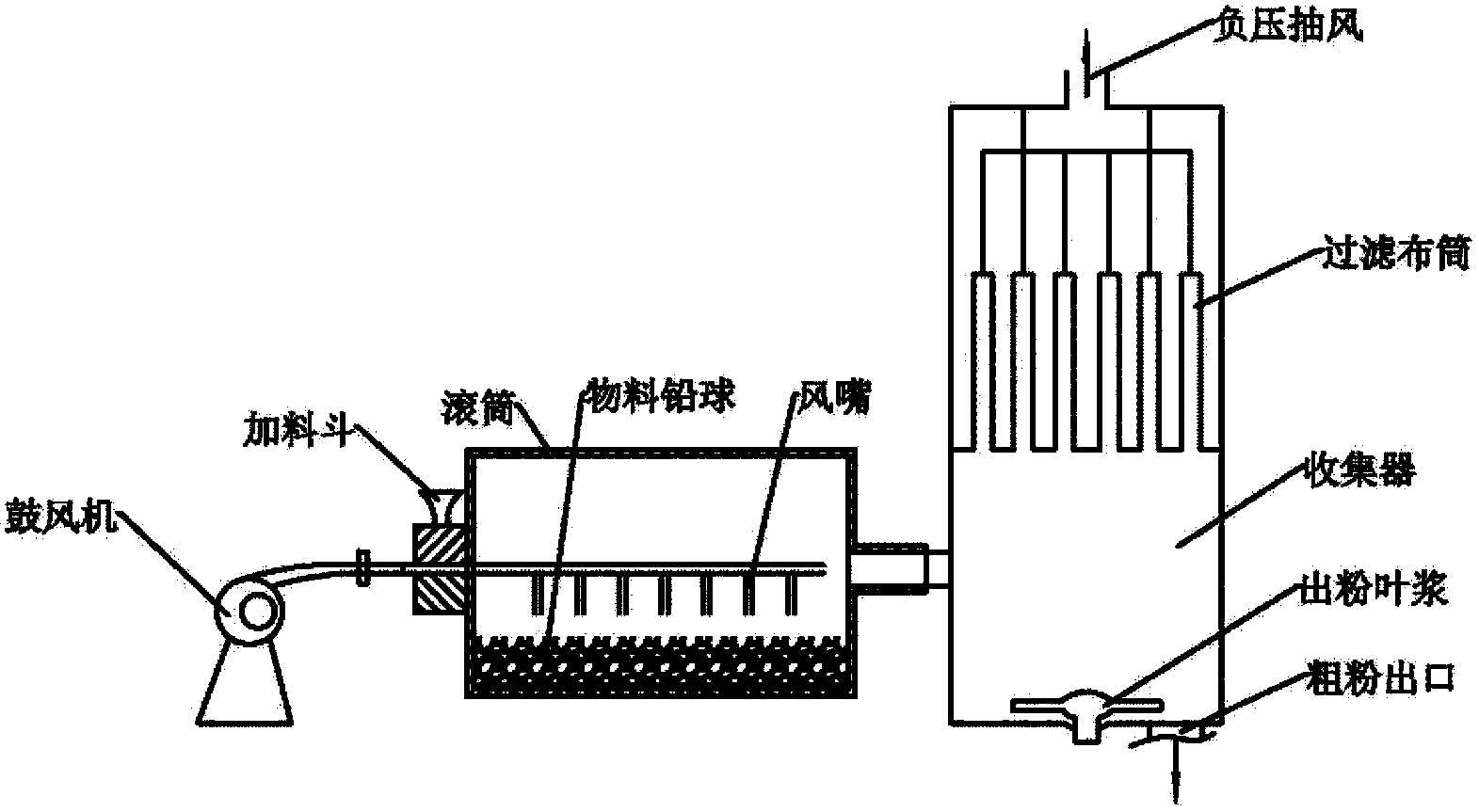

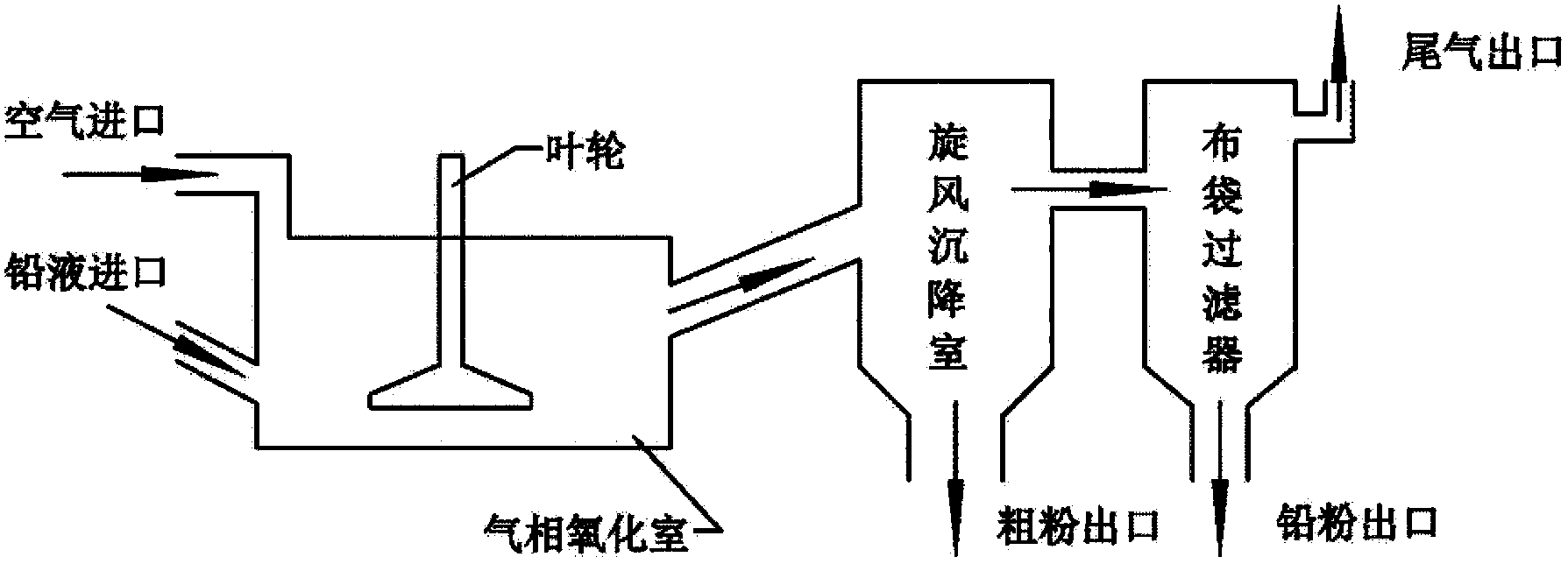

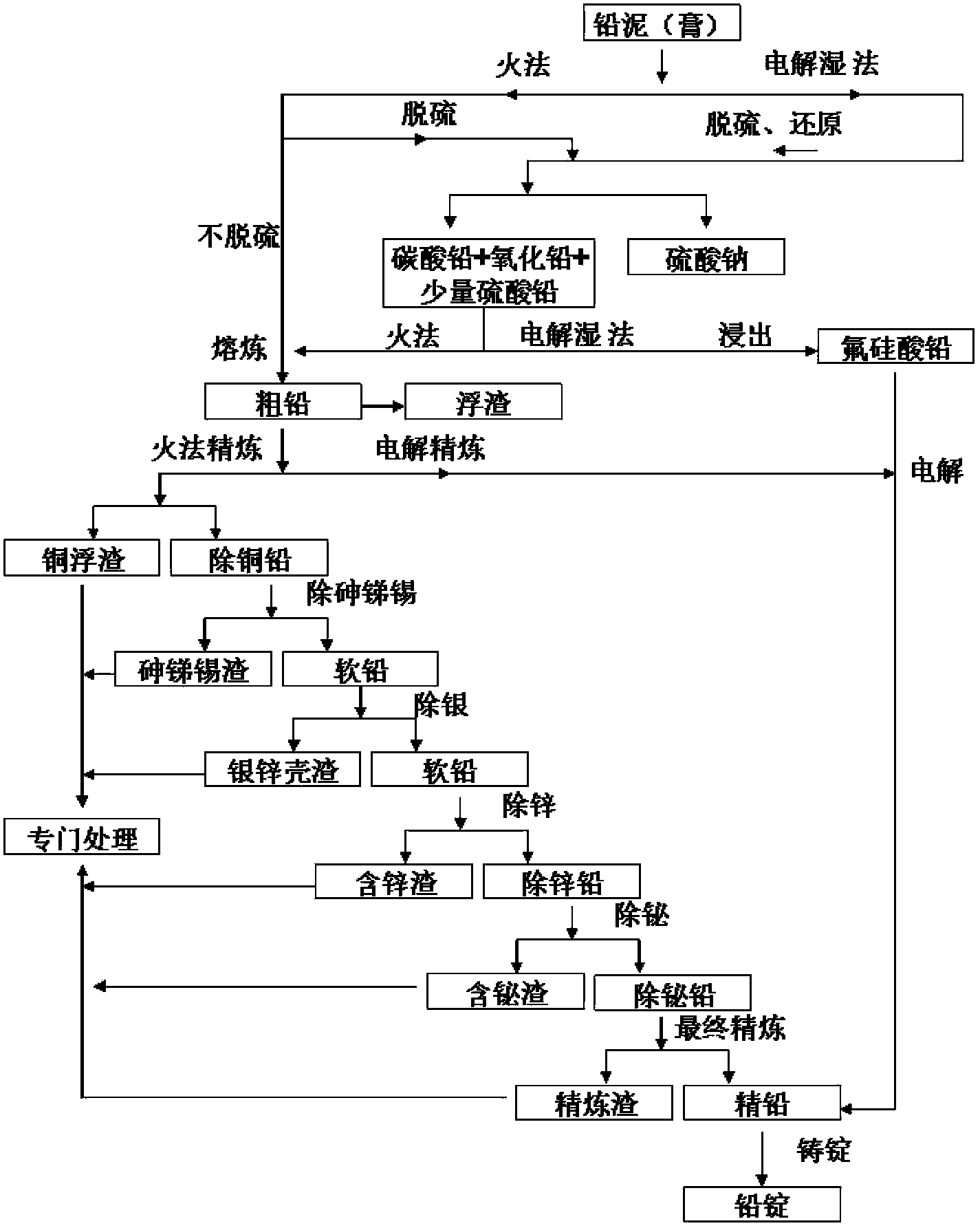

[0215] A process route suitable for chemical method 1 for wet recovery of waste lead paste and wet manufacturing of high-performance lead-acid battery electrode active materials, such as image 3 shown, and the equipment suitable for this chemical method 1 is as Figure 4 , 5 , 6 shown. in, Figure 4 The equipment in is composed of three main unit parts, that is, at least one reaction tank, at least one decomposition furnace, and at least one pulverizer, wherein the decomposition furnace is connected to the reaction tank and pulverizer respectively.

[0216] according to image 3 , the chemical reaction steps of this embodiment are as follows: (1) waste lead plaster reacts with sodium hydroxide to generate sodium sulfate solution and lead (hydroxide) oxide particles; Add acetic acid to the particle to form a solution, the solute in the solution is lead acetate and a small amount of lead dioxide, the soluble product generated by the reaction of lead and acetic acid; (3) mak...

Embodiment 2

[0229] A process route of chemical method 2 for wet recovery of waste lead paste and wet manufacturing of high-performance lead-acid battery electrode active materials and equipment suitable for chemical method 2 are as follows Figure 7 , 5 or 6.

[0230] according to Figure 7 , the chemical reaction steps of this embodiment are as follows: (1) waste lead plaster reacts with ammonium hydroxide to generate ammonium sulfate solution and lead (hydr) oxide particles; Nitric acid is added to the particles to form a solution, the solute in the solution is lead nitrate and a small amount of lead dioxide that may exist, and the soluble product generated by the reaction of lead and nitric acid; (3) The lead nitrate solution is reacted with ammonium carbonate to form Precipitation of solid particles and solution, wherein the main component of solid particles is lead carbonate particles, and the main component of solute in solution is ammonium nitrate; (4) Separating the solid particl...

Embodiment 3

[0239]A chemical method 3 for waste lead paste wet recovery and high-performance lead-acid battery electrode active material wet manufacturing process and equipment suitable for chemical method 3 are as follows Figure 8 , 5 or 6.

[0240] according to Figure 8 , the chemical reaction steps of this embodiment are as follows: (1) waste lead plaster reacts with sodium hydroxide to generate sodium sulfate solution and lead (hydr) oxide particles; Fluorosilicic acid is added to the particles to form a solution, the solute in the solution is lead fluorosilicate and possibly a small amount of lead dioxide, the soluble product formed by the reaction of lead and fluorosilicic acid; (3) lead fluorosilicate The solution reacts with sodium hydroxide to generate solid particle precipitation and solution, wherein the main component of the solid particle is lead hydroxide, and the main component of the solute in the solution is sodium fluorosilicate; (4) Separating the solid particle from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com