Solvent process for preparation of high-quality coal-based needle coke

A high-quality, needle-shaped coke technology, applied in the field of coal chemical industry, can solve the problems of high content, high solubility, unsatisfactory quinoline, etc., and achieve high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

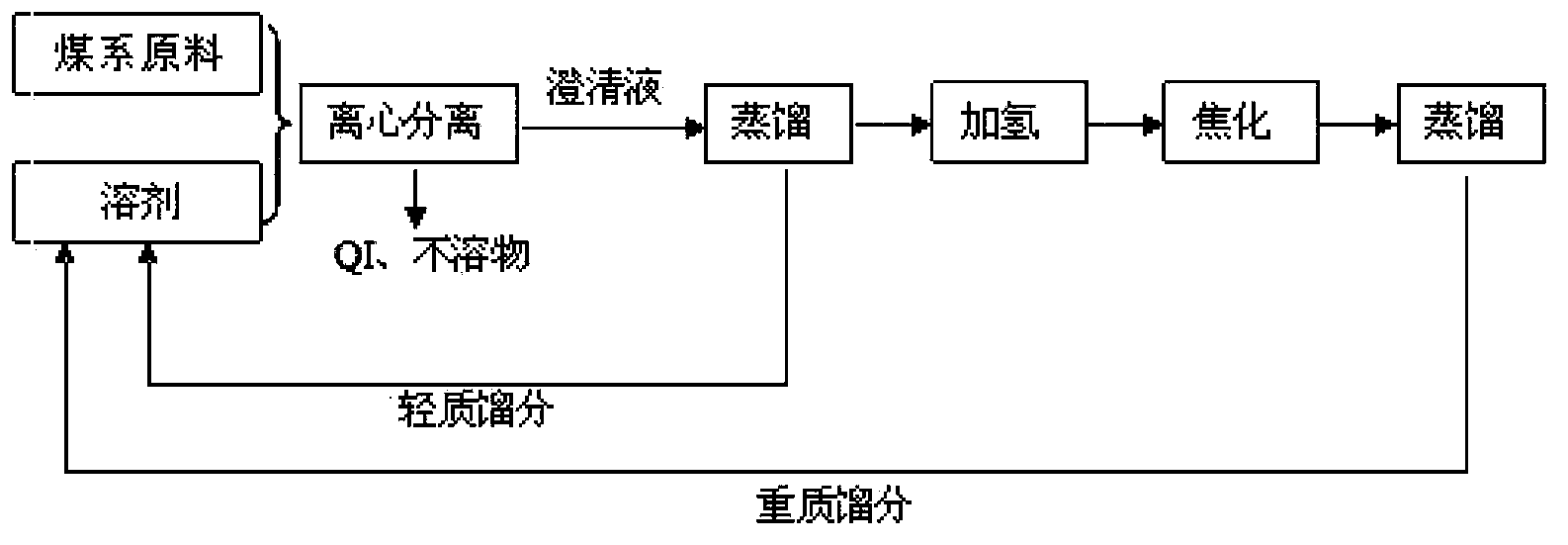

Method used

Image

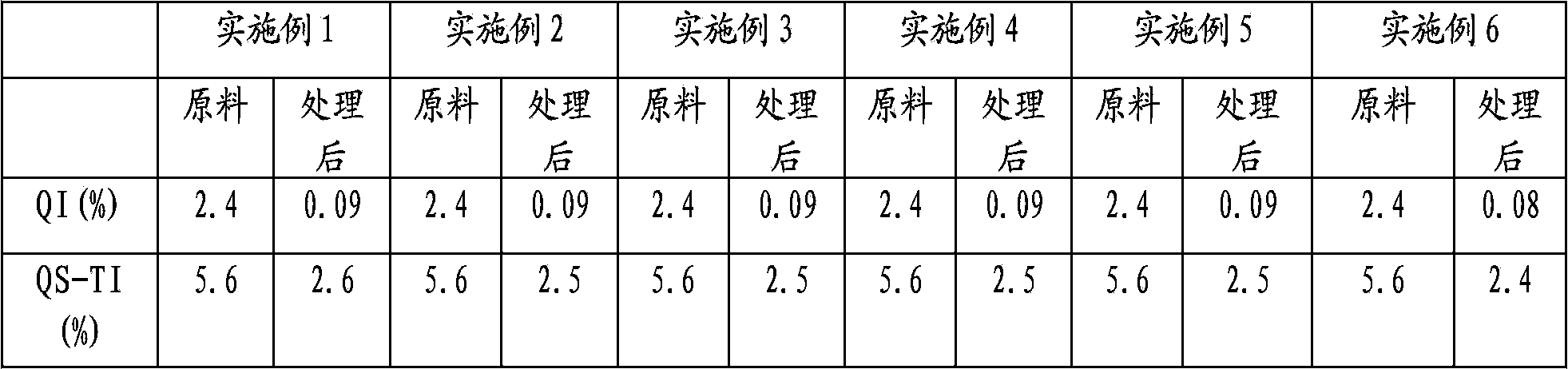

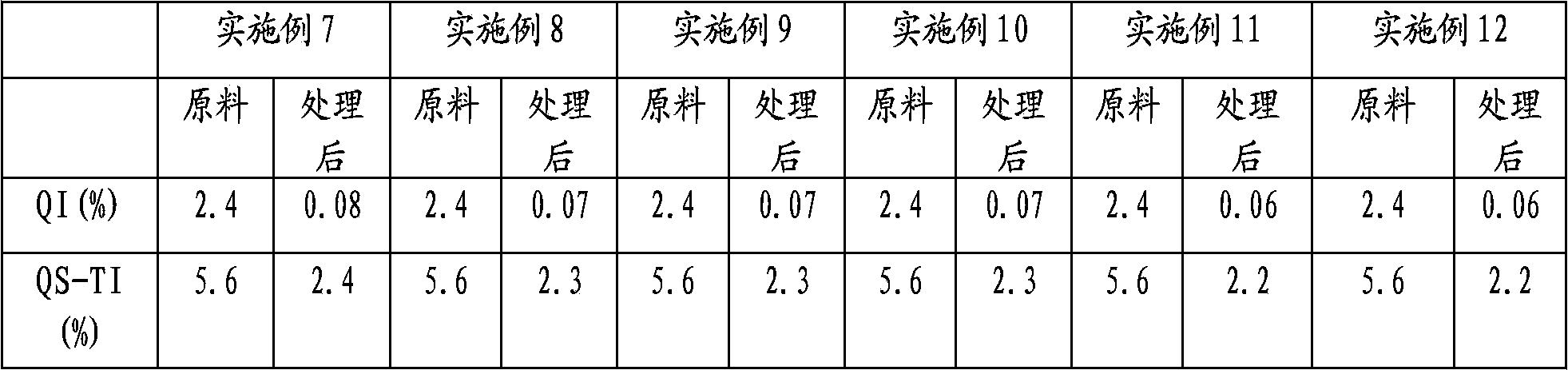

Examples

Embodiment 1

[0042] The process for preparing high-quality coal-based needle coke using the solvent method described in this example includes the following steps:

[0043] (1) Preparation of solvent: pump the coal tar into the first hydrogenation reactor, set the temperature at 300°C, and the pressure at 20Mpa, add SAS-10 type dearsenic and desulfurization catalyst, carry out hydrogenation treatment on the coal tar, and put The product obtained by hydrotreating is sent to the first distillation tower for distillation, and the heavy distillate at 200°C-300°C obtained by fractional distillation is used as a solvent.

[0044] (2) Mix the coal tar with the solvent, stir evenly, remove the solvent-insoluble matter by sedimentation and separation to obtain a clear liquid, the time of sedimentation and separation in this embodiment is 24 hours, and the mass ratio of the solvent to the coal tar is 0.5 ;

[0045] (3) Pump the clarified liquid into the second hydrogenation reactor, set the temperat...

Embodiment 2

[0049] The process for preparing high-quality coal-based needle coke using the solvent method described in this example includes the following steps:

[0050] (1) Preparation of solvent: pump coal tar pitch into the first coking tower, set the temperature at 400°C and pressure at 0.1Mpa, coke the coal tar pitch, send the oil and gas produced by coking into the first distillation tower for Distillation, using the coal-based heavy distillate at 200°C-300°C obtained by fractional distillation as a solvent;

[0051] (2) Mix the coal tar pitch with the solvent, stir evenly, and then use sedimentation to separate and remove solvent-insoluble matter to obtain a clear liquid. The time for sedimentation and separation in this example is 24 hours. The mass ratio of the solvent to the coal tar pitch is is 10;

[0052] (3) Pump the clarified liquid into a fixed-bed hydrogenation reactor, set the temperature at 330°C, and set the pressure at 19Mpa, add FHRS-2 hydrogenation silicon repleni...

Embodiment 3

[0056] The process for preparing high-quality coal-based needle coke using the solvent method described in this example includes the following steps:

[0057] (1) Preparation of solvent: pump the distillate oil at 200-350°C obtained by distilling coal tar, set the temperature at 300°C, and the pressure at 20Mpa, add FHRS-2 hydrogenation and silicon-replenishing catalyst, and process the coal tar pitch Hydrotreating, the product obtained by hydrotreating is sent to the first distillation tower for distillation, and the coal-based heavy distillate at 200°C-300°C obtained by fractional distillation is used as a solvent, and the solvent also contains petroleum-based raw materials obtained by fractional distillation 200°C-300°C petroleum-based heavy distillate, the mass ratio of the coal-based heavy distillate to the petroleum-based heavy distillate is 5:95. (2) Mix the coal tar pitch with the solvent, stir evenly, and then use sedimentation to separate and remove solvent-insoluble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com