Preparation method of hydrophilic magnetic halloysite surface molecularly-imprinted nano composite material

A technology of nanocomposite materials and surface molecular imprinting, which is applied to chemical instruments and methods, water pollutants, alkali metal compounds, etc., to achieve uniform size, excellent regeneration performance, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] (1) Preparation of magnetic halloysite

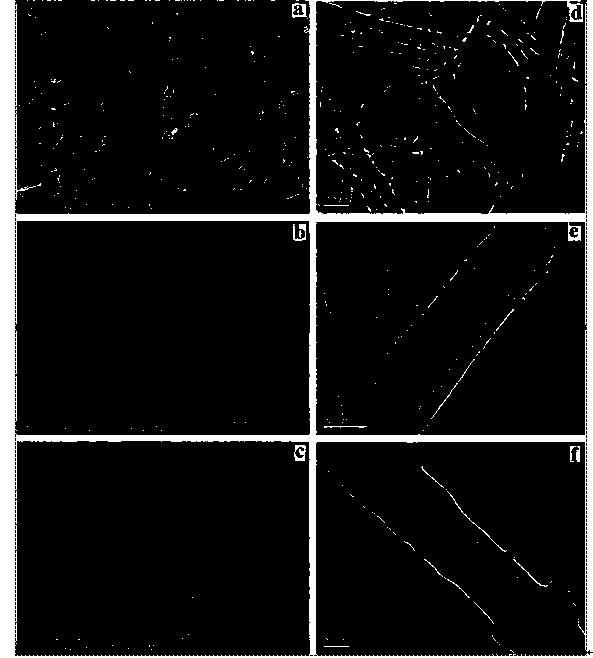

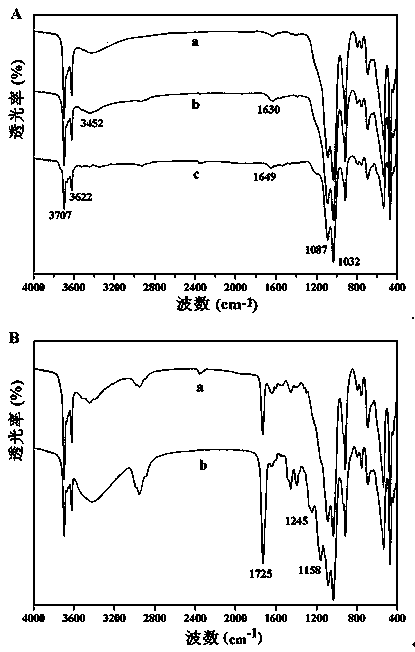

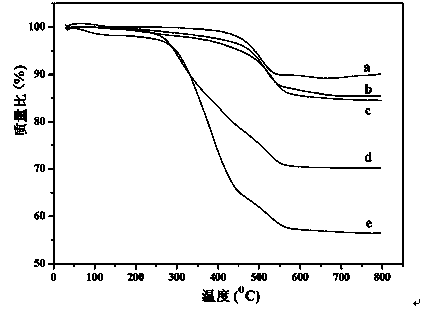

[0031] Add 20 mL of ethanol, 1.0 g of halloysite, and 0.8 g of ferric nitrate nonahydrate to a 50-ml flask in sequence, ultrasonically disperse evenly, and stir magnetically at room temperature for 16 h. o C oven dry. After grinding, put it into a magnetic boat, add 3.0 mL of ethylene glycol (EG) dropwise, fully soak for 12 h, and heat in a tube furnace at 4.0 oC / min heat up to 400 o C, Calcined at this temperature for 2.0 h, the calcined product was washed with ethanol several times, and dried to constant weight to obtain magnetic halloysite (MHNTs). From figure 1 It can be seen that the magnetic nanoparticles are evenly distributed inside and outside the pores of halloysite, and have strong magnetic saturation (such as Figure 4 shown).

[0032] (2) Magnetic halloysite surface grafting initiator

[0033] Add 1.0 g magnetic halloysite, 2.0 mL gamma -Aminopropyltriethoxysilane and 100 mL toluene, ultrasonically disperse...

experiment example 2

[0045] Experimental example 2: Take 10 ml of sulfamethazine solution with an initial concentration of 100 μmol / L and add it to a centrifuge tube, add 5.0 mg of HMMINs and HMNINs respectively, and place the test solution at 25 o C in a water bath for 10, 20, 30, 45, 60, 90 and 120 minutes. After standing still, the supernatant was collected by magnetic separation, and the concentration of unadsorbed sulfamethazine molecules was measured with an ultraviolet-visible spectrophotometer, and the adsorption capacity was calculated according to the results. Figure 7 The results showed that HMMINs and HMNINs had good adsorption kinetics for sulfamethazine, and the adsorption equilibrium was basically reached within 45 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com