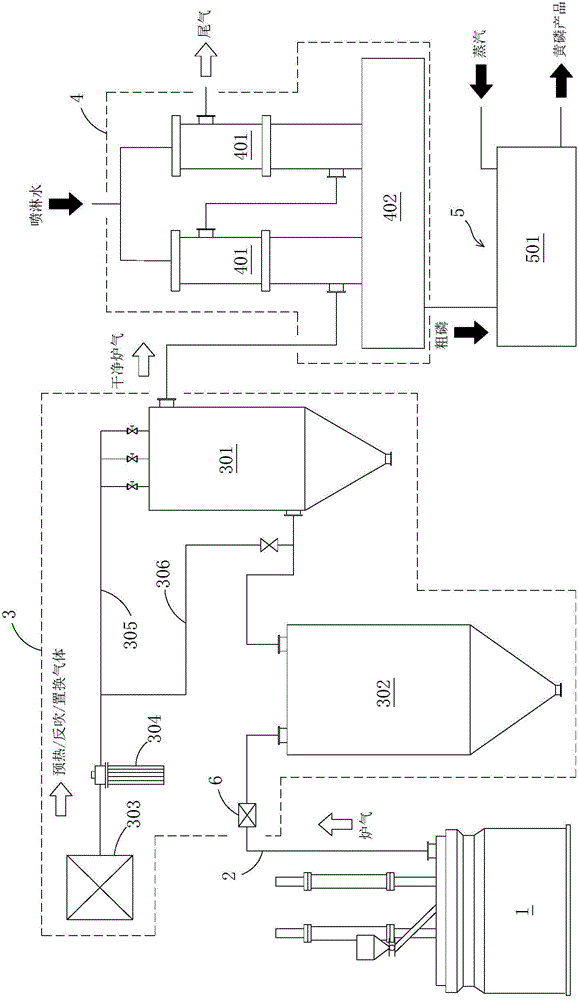

Yellow phosphorus preparation method and yellow phosphorus preparation equipment

A yellow phosphorus and equipment technology, applied in the field of yellow phosphorus preparation, can solve the problems of high technical requirements for personnel, huge construction cost of electrostatic precipitator supporting facilities, high operation and maintenance costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

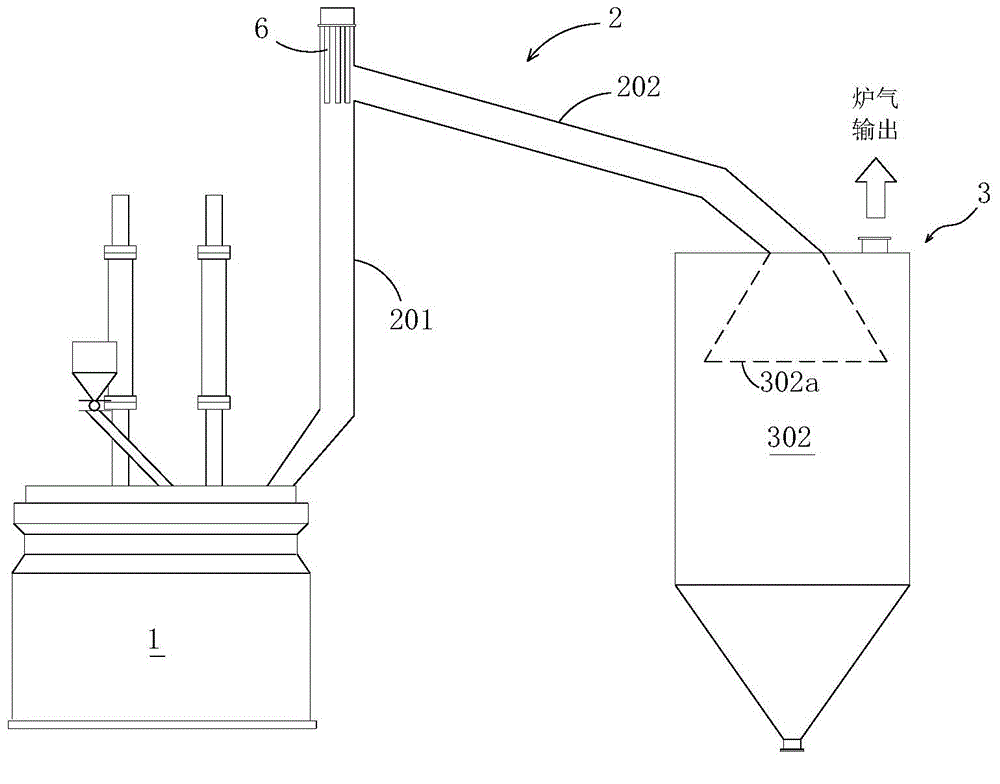

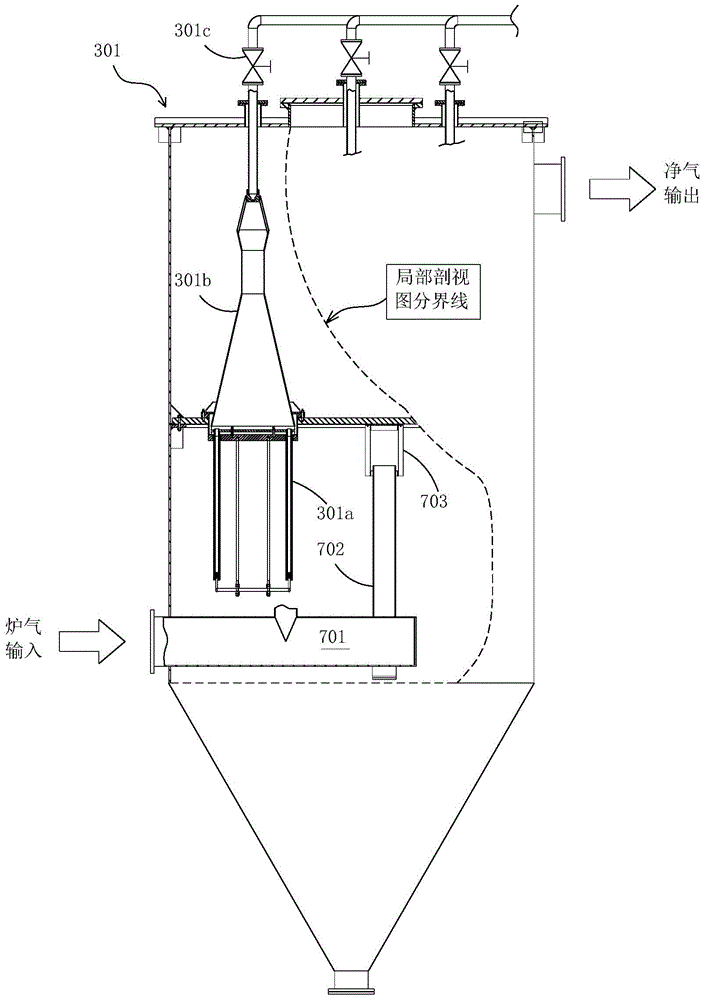

Embodiment 1

[0070] A multi-electrode phosphorus electric furnace with a transformer capacity of 15000KVA is used. 50 tons of the mixture is continuously added to the electric furnace 1 for reaction, and at the same time, the gas supply device 303 and the heater 304 are activated, and the high-temperature inert preheated gas passes through the second output pipe 306 and enters the filter 301 from the furnace gas inlet pipe to be filtered. The sintered inorganic porous material filter element (using FeAl intermetallic compound porous material filter element) in the filter 301 is preheated to 187.5°C, and then the valve on the second output pipe 306 is closed. After that, the furnace gas discharged from the electric furnace 1 is introduced into the furnace gas dust collection system 3 through the exhaust pipe 2, during which the furnace gas is heated by the heat exchange device 6. The heated furnace gas discharged from the electric furnace 1 first enters the mechanical dust collector 302 thro...

Embodiment 2

[0072] After the end of Example 1, the equipment is directly used to proceed to Example 2. The second batch of 50 tons of mixed material is continuously added to the electric furnace 1 for reaction, and at the same time, it is switched to another refining pot 501. The furnace gas discharged from the electric furnace 1 is introduced into the furnace gas dust collection system 3 through the exhaust pipe 2, during which the furnace gas is heated by the heat exchange device 6. The heated furnace gas discharged from the electric furnace 1 first enters the mechanical dust collector 302 through the flue gas duct 2 for primary dust removal and purification, and then enters the filter 301 for secondary dust removal and purification. It is detected that the temperature of the furnace gas to be filtered is maintained at about 250°C on the gas inlet pipe of the filter 301 to be filtered. The filter 301 starts on-line blowback every 600s. During the blowback, the inert blowback gas output ...

Embodiment 3

[0074] After the end of Example 2, the equipment is directly used to proceed to Example 3. The third batch of 50 tons of mixed material is continuously added to the electric furnace 1 for reaction, and at the same time, it is switched to another refining pot 501. The furnace gas discharged from the electric furnace 1 is introduced into the furnace gas dust collection system 3 through the exhaust pipe 2, during which the furnace gas is heated by the heat exchange device 6. The heated furnace gas discharged from the electric furnace 1 first enters the mechanical dust collector 302 through the flue gas duct 2 for primary dust removal and purification, and then enters the filter 301 for secondary dust removal and purification. It is detected that the temperature of the furnace gas to be filtered is maintained at about 300°C on the gas inlet pipe of the filter 301 to be filtered. The filter 301 starts on-line blowback every 600s. During the blowback, the inert blowback gas output b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com