A swing arm mechanism for reciprocating and moving wall and floor tiles

A technology of reciprocating swing, wall and floor tiles, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of increasing the use and maintenance cost of the swing arm device, difficult to achieve positioning of the end of the swing arm, and affecting the reliability of the swing device. Simple mechanical structure and electrical control method, improve motion accuracy, and relieve impact load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with a specific embodiment:

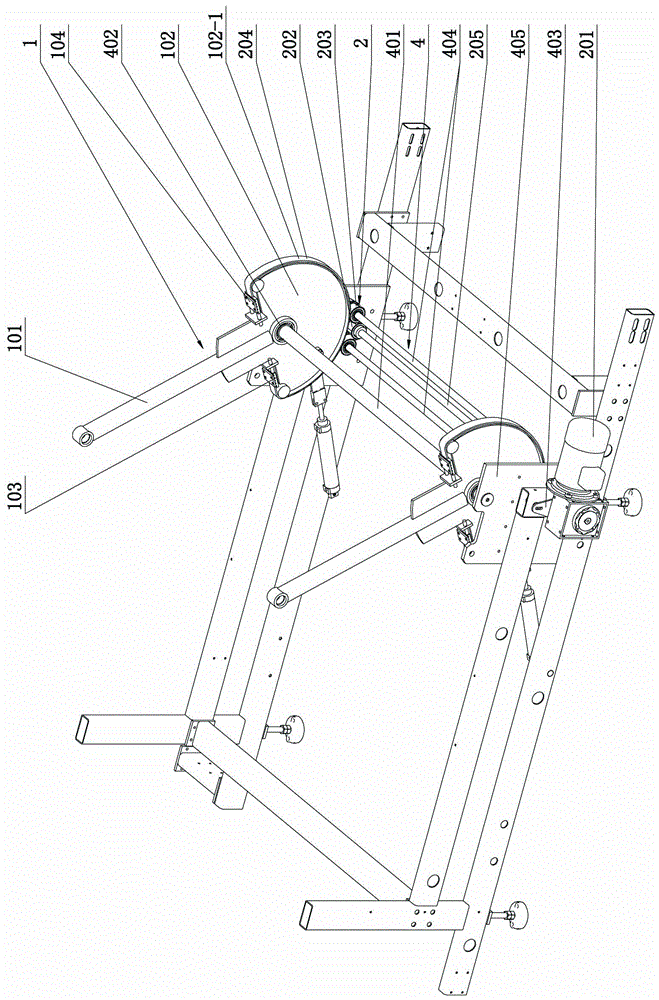

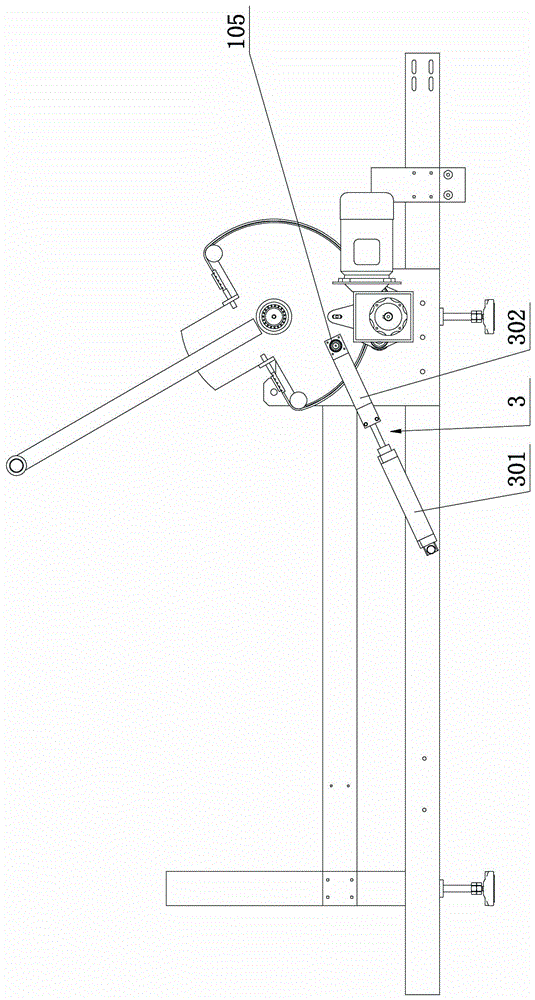

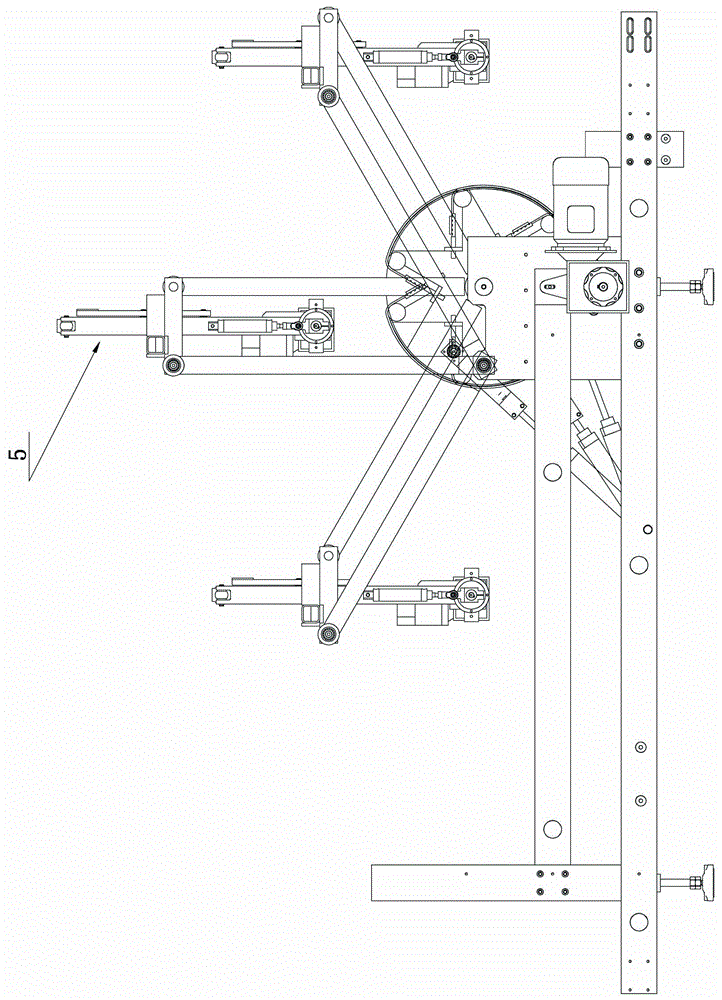

[0016] See attached Figure 1 to Figure 3 As shown, a swing arm structure for reciprocatingly swinging and transferring wall and floor tiles described in this embodiment. It includes a swing arm assembly 1, a swing arm drive assembly 2, a base 4 and a wall and floor tile gripping device 5. The swing arm assembly 1 includes a swing arm 101 on both sides, a swing wheel 102, a timing belt joint 103, and a timing belt splint 104; the swing arm drive assembly 2 includes a reduction motor 201, a drive shaft 205, and timing belt drive wheels on both sides 202, the timing belt guide wheel 203 and the timing belt 204; the base 4 includes a shaft 401 and a bearing 402 supporting the swing arm assembly 2, a set of support shafts 404 supporting the timing belt guide wheel 203, a bearing seat 405 supporting the drive shaft 205 and Fix the fixed seat 403 of the geared motor 201.

[0017] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com