Soundproof material using polyurethane foam from car seat and fabrication process thereof

A polyurethane foam and sound-insulating material technology, applied in chemical instruments and methods, vehicle parts, non-woven fabrics, etc., can solve problems such as fiber dust, poor sound-absorbing properties, and poor sound-insulating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

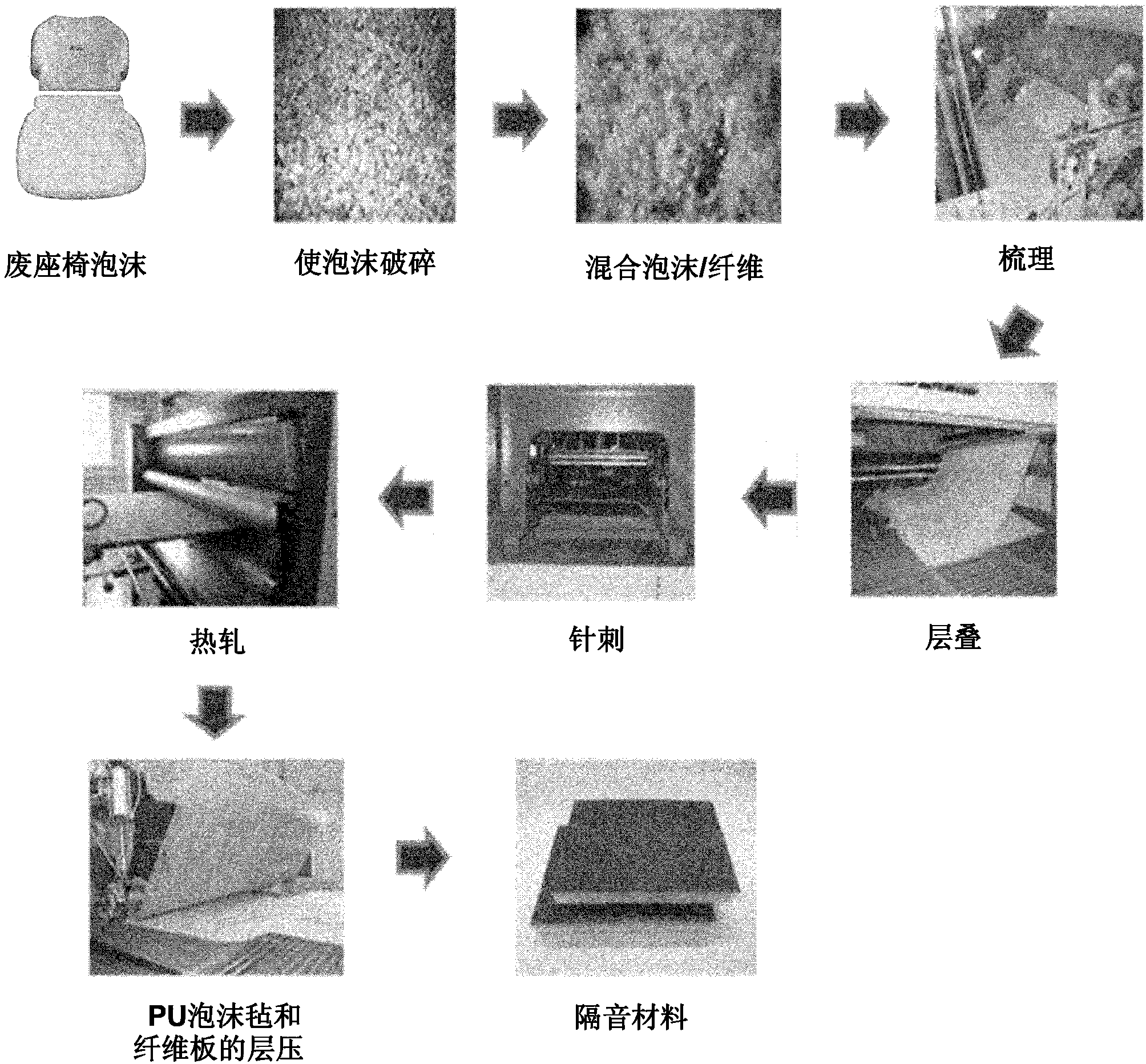

[0077] According to another embodiment of the present invention, there is provided a method of manufacturing a sound-insulating material, the method comprising the steps of:

[0078] (a) breaking the PU foam, preferably polyurethane foam from vehicle waste seats, into fine particles;

[0079] (b) by mixing the crushed PU foam obtained in step (a) with polyester-based fibers and low-melting-point polyester-based fibers to produce a sound-absorbing material;

[0080] (c) carding sound-absorbing materials;

[0081] (d) needle-punched sound-absorbing materials;

[0082] (e) thermoforming and cooling the sound-absorbing material, in particular to provide a felt shape;

[0083] (f) To manufacture sound-insulating materials by mixing polyester fibers, low-melting polyester fibers, and PP fibers;

[0084] (g) combing sound-proofing materials;

[0085] (h) needle-punched sound-insulating materials;

[0086] (i) thermoforming and cooling the sound insulation material, in particular...

Embodiment 1

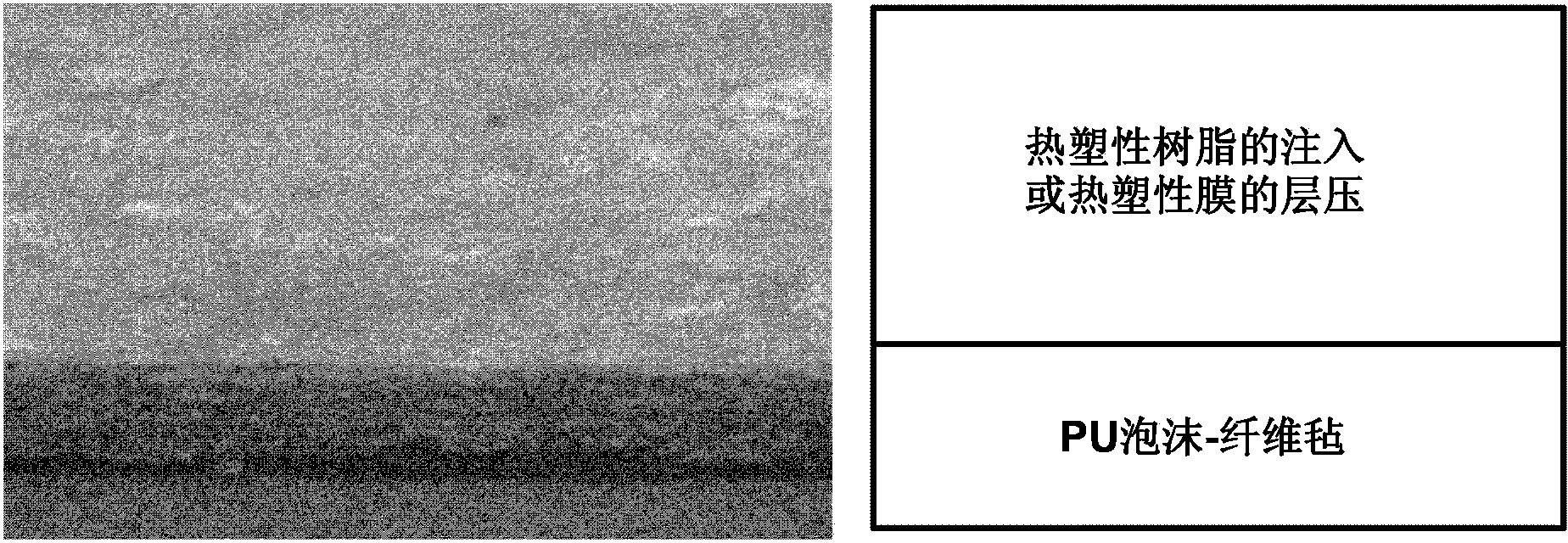

[0100] 10wt% of PET fiber, 10wt% of LM (low melting point) PET fiber, 10wt% of PP fiber, and 20wt% of thermoplastic resin were introduced into 50wt% of Obtained thermosetting polyurethane foam. As a result of this process, at least some thermoplastic resin is injected instead of fibers, which increases the mechanical strength of the product, but results in the mixture being partially coated with molten thermoplastic resin, which reduces the sound-absorbing properties and dimensional stability of the product.

Embodiment 2

[0102] 10wt% PET fiber, 10wt% LM PET fiber, 20wt% PP fiber, and 50g / m 2 The thermoplastic film of ® was incorporated into 50 wt% of thermoset polyurethane foam obtained by crushing PU foam from scrapped vehicle seats into fine particles. The products manufactured by laminating thermoplastic films thereon had better sound insulation properties and higher mechanical strength than those manufactured according to Comparative Examples 1 and 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com