Cleaning device and cleaning method

A washing device and washing liquid technology, which is applied in the direction of chemical instruments and methods, spraying devices, cleaning methods and appliances, etc., can solve the problems of coating defects, affecting the discharge of coating liquid, etc., and achieve the effect of low-cost structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Embodiments of the present invention are described with reference to the drawings.

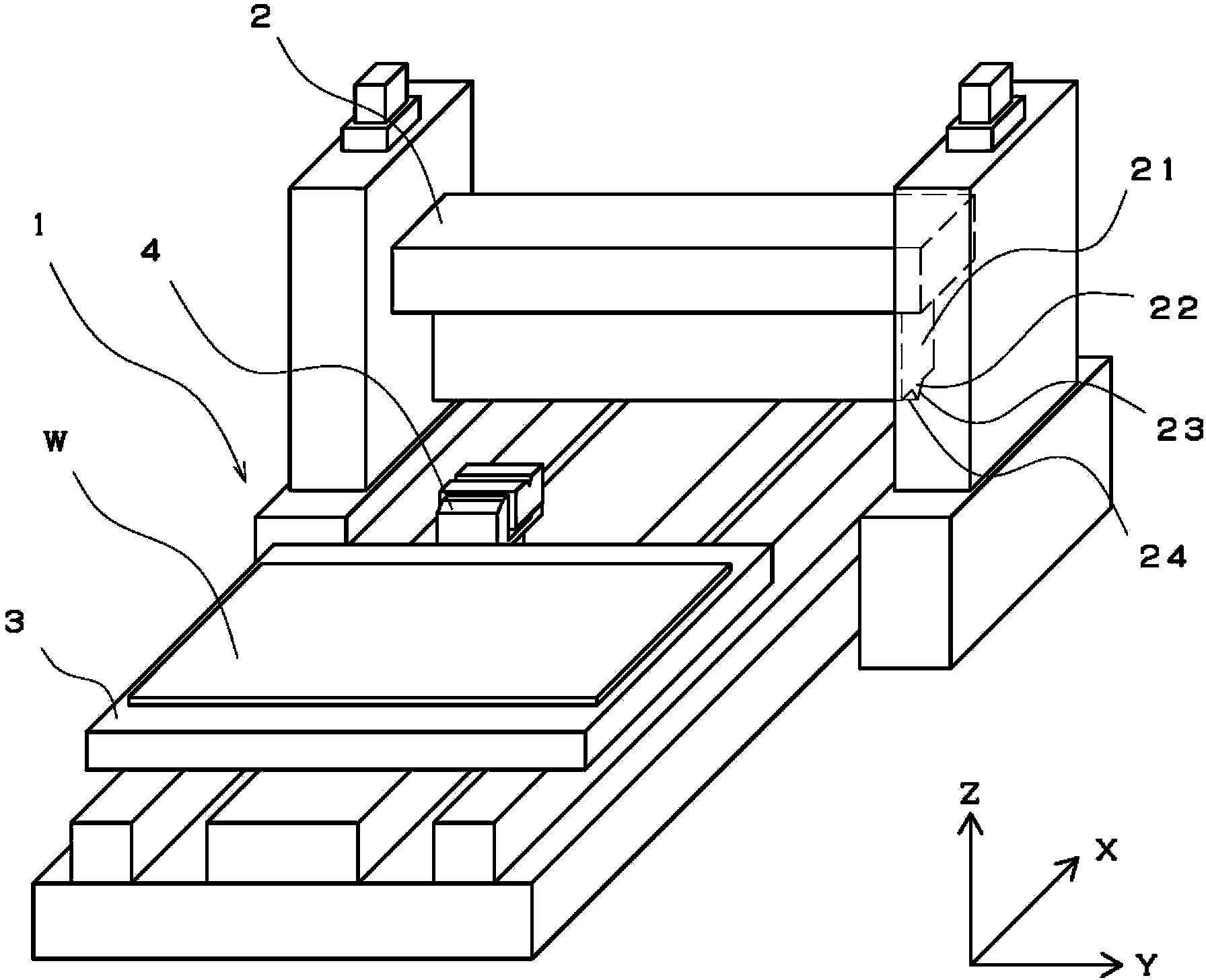

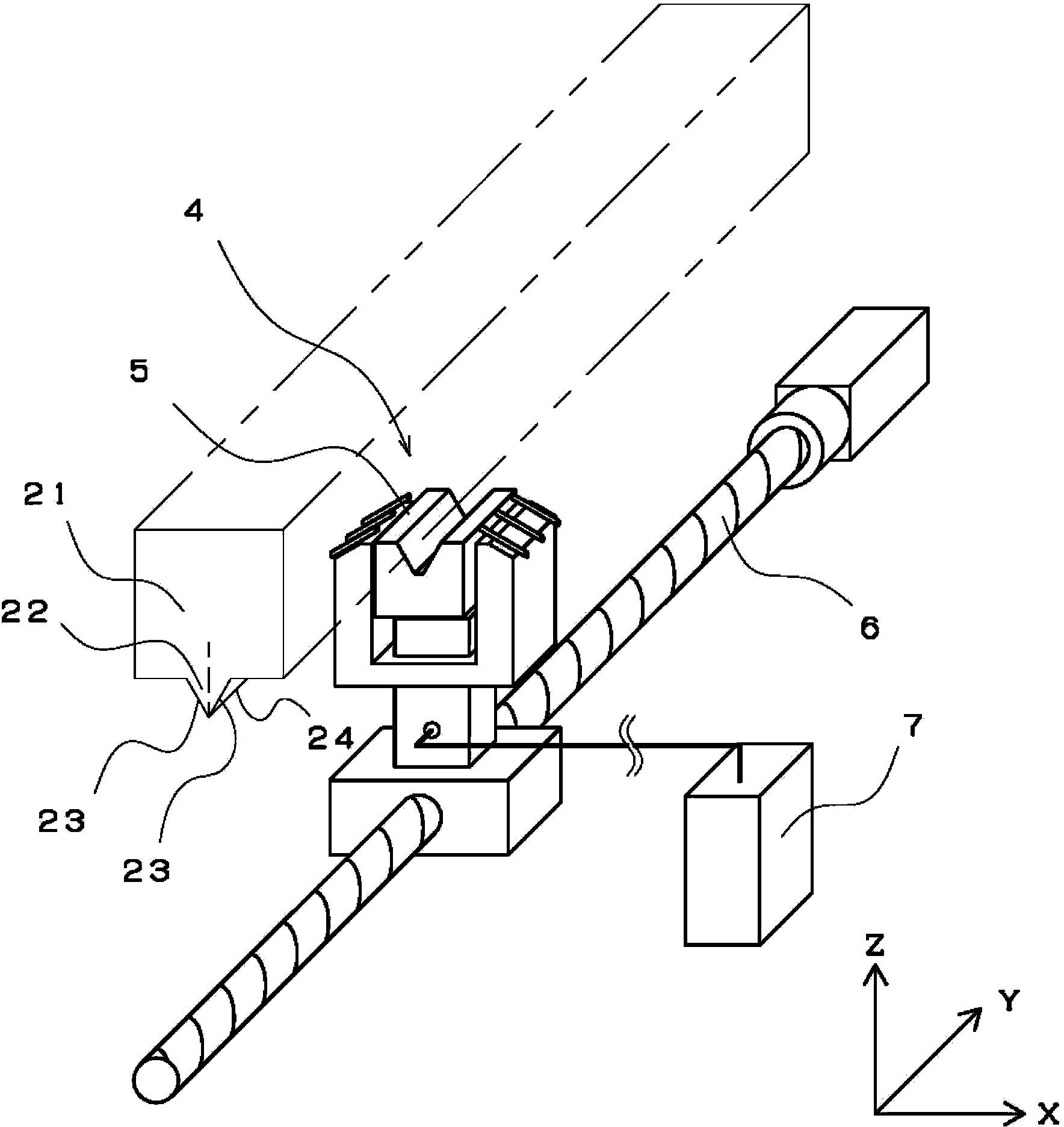

[0070] figure 1 It is a schematic diagram of a coating device using the cleaning device of the present invention. The coating device 1 includes: a coating unit 2 for coating the coating liquid on the substrate W; a transport unit 3 for transporting the substrate W; and a washing device 4 of the present invention for washing the lip surface 23 described later.

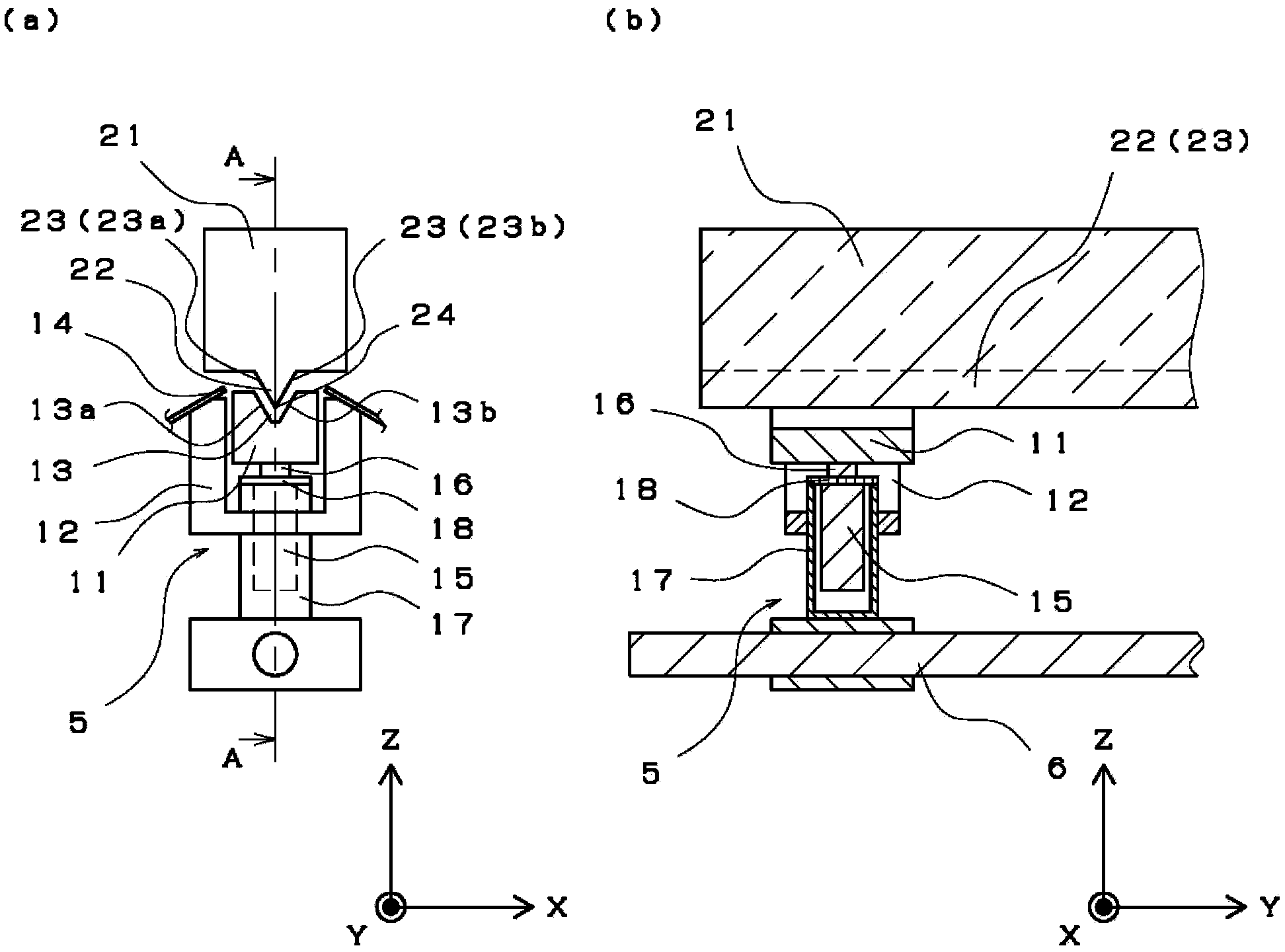

[0071] The coating unit 2 includes a nozzle 21 inside which has a slit whose longitudinal direction is the direction perpendicular to the transport direction of the substrate W transported by the transport unit 3 . In addition, a lip 22 is provided on the lower portion of the head 21 .

[0072] as explained later image 3 As shown in (a), the lip 22 has a shape protruding from the pipe head 21 to the downward with a pointed mouth shape, and the lip 22 has two inclined lip surfaces 23 ( image 3 (a) shows the lip surface 23a a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com