An intermediate frequency induction motor for evaporative cycle refrigeration

An induction motor and electric motor technology, which is applied to the starter, motor generator/starter, and electric components of a single multi-phase induction motor, can solve the problems of increasing the volume and weight of the starter box, large active power loss, etc. The effect of compactness, ensuring safe operation, improving service life and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

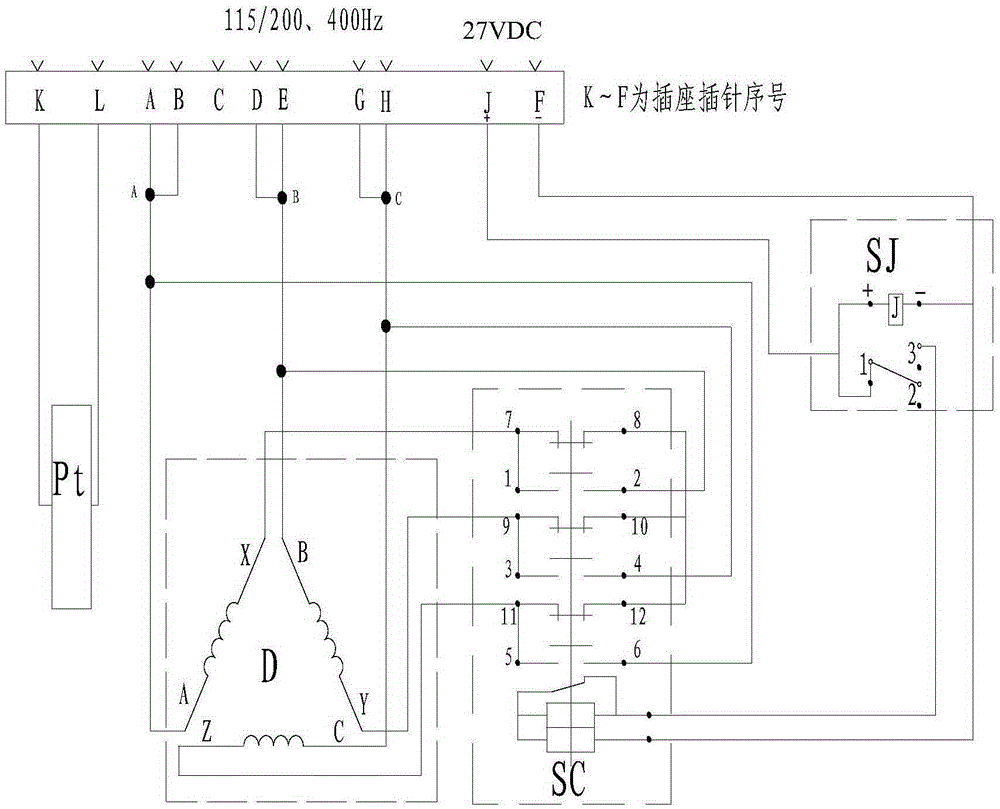

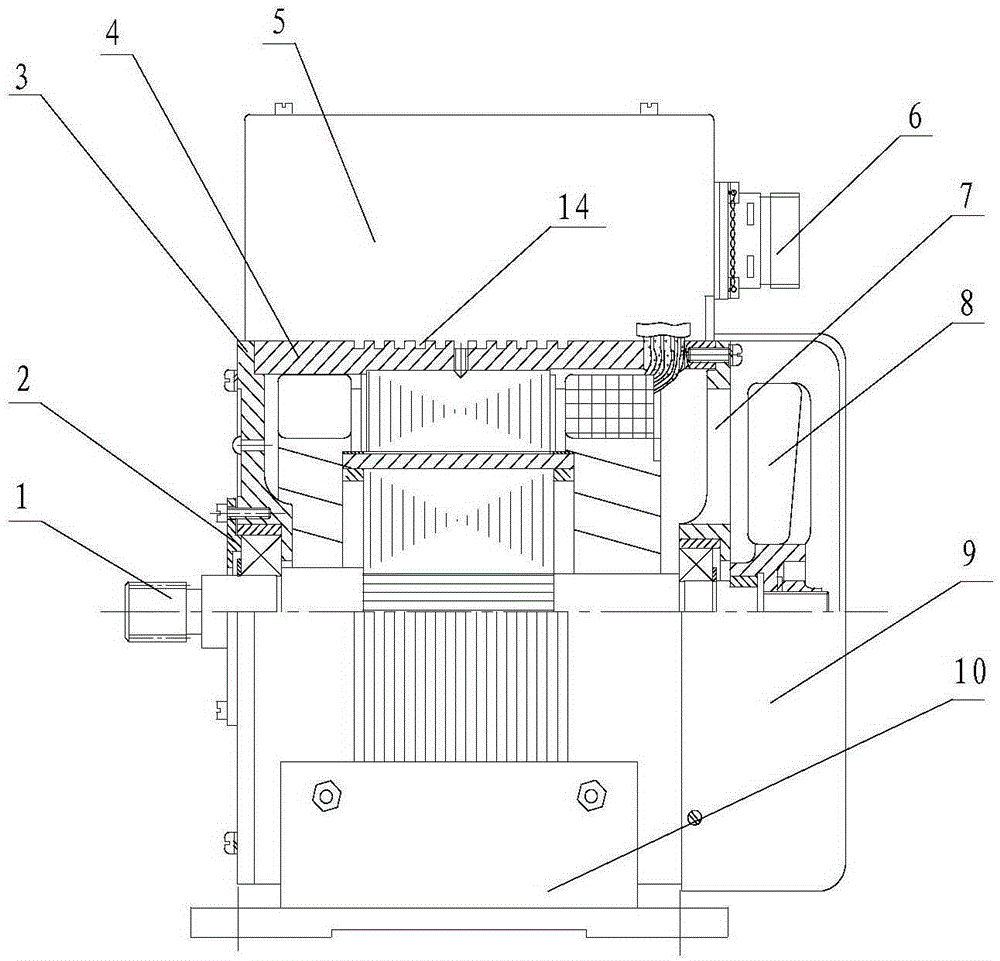

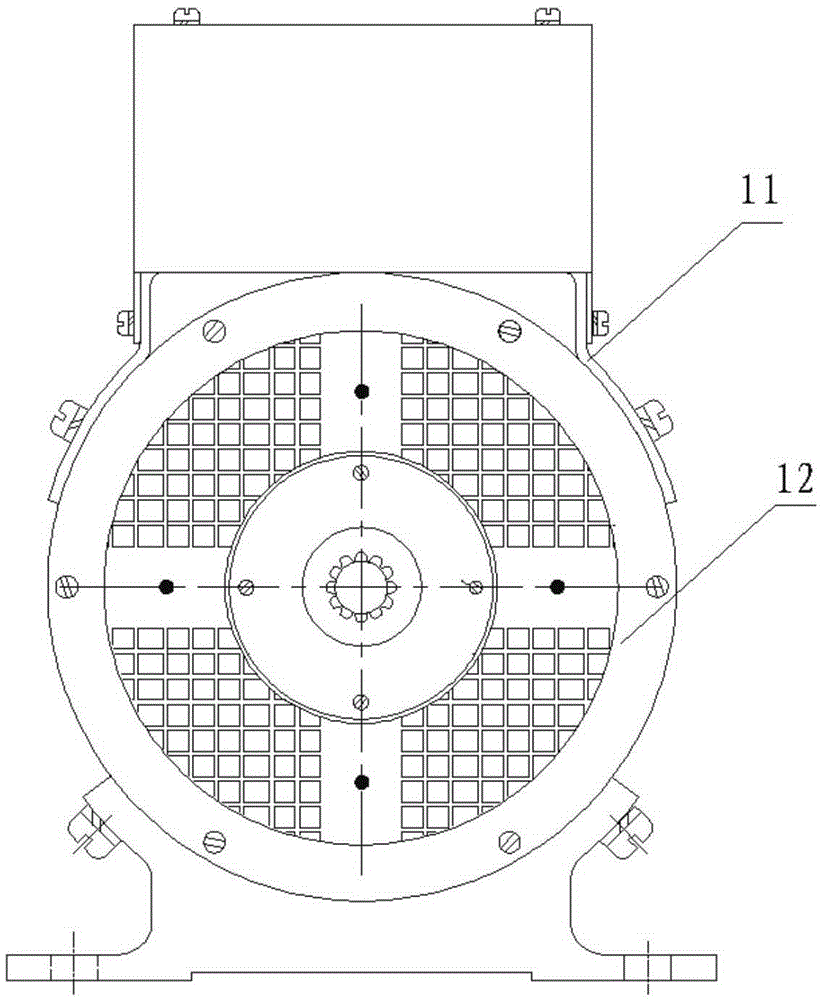

[0030] The technical solution of the embodiment of the present invention is: the stator winding of the motor adopts three-phase symmetrical double-layer stacked windings, the three-phase windings are independently output, and there are six outlets in total, and the outlets of the three-phase windings are connected to the starter box assembly 5 . The starter box assembly 5 includes: a starter box base 11, a sealed hybrid delay relay SJ, a three-phase AC contactor SC, and the like. When starting, the evaporative cycle refrigeration system controls 115 / / 200VAC, 400Hz AC power supply and 27VDC DC power supply to be connected at the same time, the delay relay SJ starts timing, and the stator winding ends x, y, z are normally closed with the three-phase AC contactor SC respectively. Contacts 7 and 8, 9 and 10, 1 and 12 are connected, and the stator winding of the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com