Auxiliary starting system and method for vacuum furnace motor

A start-up system and vacuum furnace technology, which is applied in the direction of machine/engine, mechanical equipment, pump control, etc., can solve the problem of large start-up current of fans, and achieve the effect of solving large start-up current and reducing start-up current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

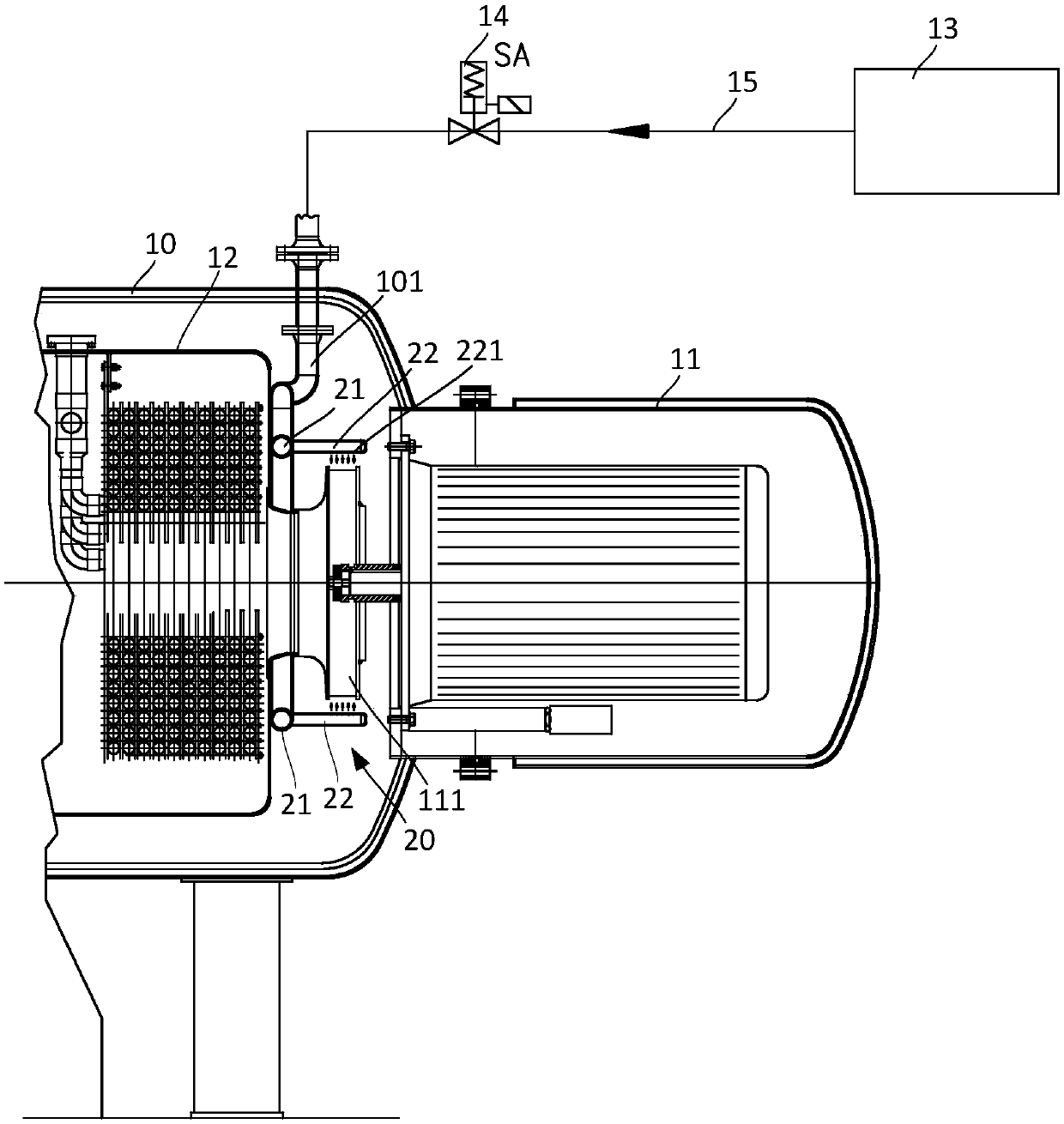

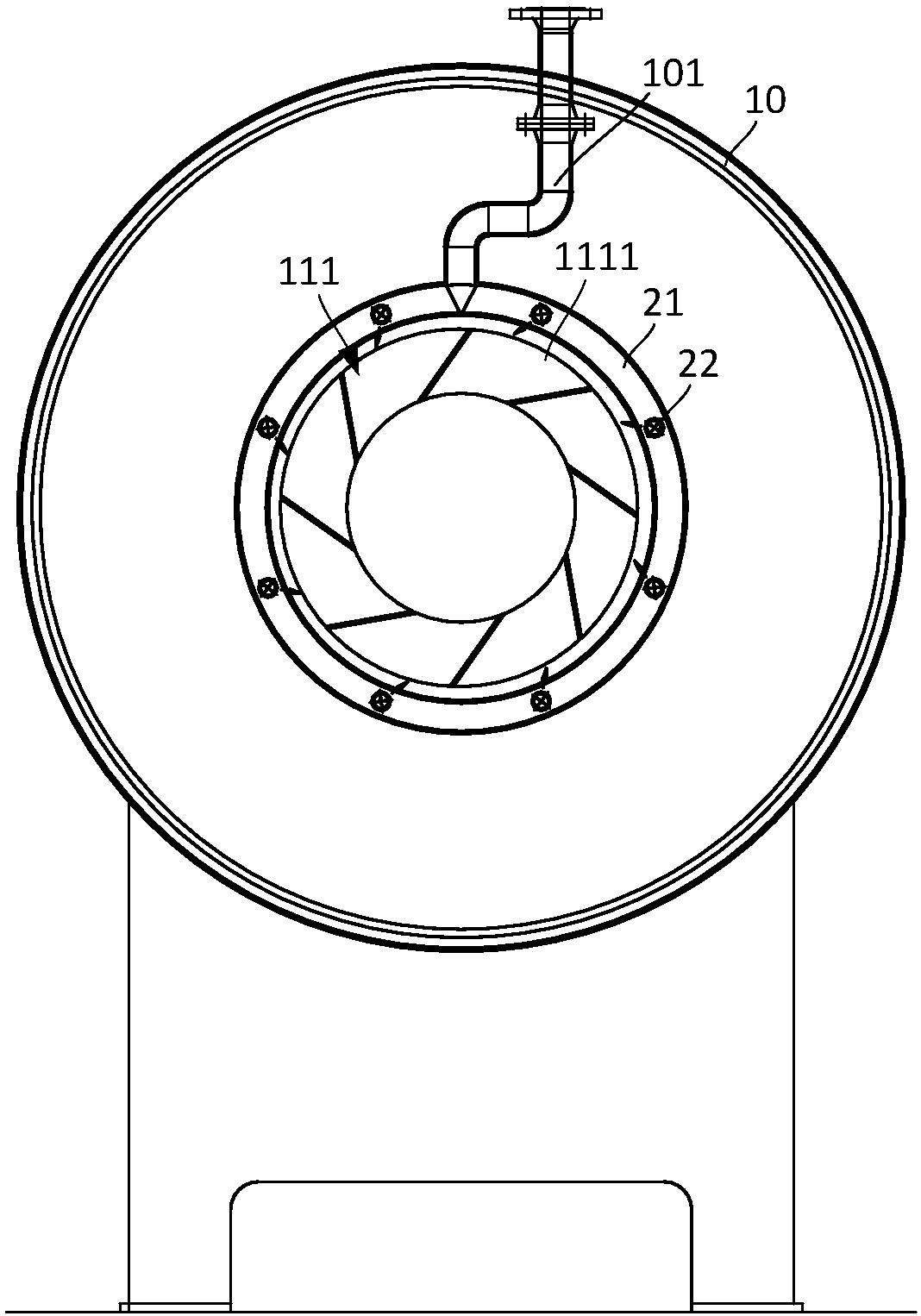

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] refer to figure 1 , The invention provides an auxiliary starting system and method for a vacuum furnace motor, which is used to solve the problem that the power and starting current of the fan on the vacuum furnace are very large in a gas environment of 20 bar. The auxiliary starting system of the present invention makes full use of the stage of filling the vacuum furnace with high-pressure gas, and uses the charged high-pressure gas to drive the impeller of the fan to rotate. When the impeller reaches a certain speed, the fan is started, thereby reducing the starting current and saving energy consumption. , effectively solve the problem of large starting current of the fan. The auxiliary starting system and method of the vacuum furnace motor of the present invention will be described below in conjunction with the accompanying drawings....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com