Rapid detection method and device for ferrous oxide in sintered ores

A ferrous oxide, rapid detection technology, applied in the direction of material magnetic variables, etc., can solve the problems that the detection reproducibility cannot guarantee the practical application of sintering production, can not meet the needs of fast, timely guidance of sintering production, and cannot distinguish the valence state of elements, etc. Achieve the effect of saving material cost, good test stability and large sampling volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0031] A kind of rapid determination method of ferrous oxide in sintered ore, specifically comprises the following steps

[0032] (1) Sample pretreatment

[0033] After the sinter sample to be tested is ground into powder, it passes through a 160-180 mesh screen and is sent to a sample press (manufacturer: Changchun Keguang Electromechanical Equipment Co., Ltd., model: YYJ-40). Under the condition of a pressure of 40t, Continue to press for 30s to obtain the sheet sample to be tested; through sample pretreatment, control the sample particle size, volume, sample volume, pressure, and continuous pressing time to make the standard curve of the sinter sample consistent with the bulk density of the sample block to be tested, that is, to ensure The experimental test conditions are the same;

[0034] (2) Standard curve establishment

[0035] Accurately weigh a series of sinter standard samples equal to the weight of the sinter samples to be tested, grind a series of si...

specific Embodiment 2

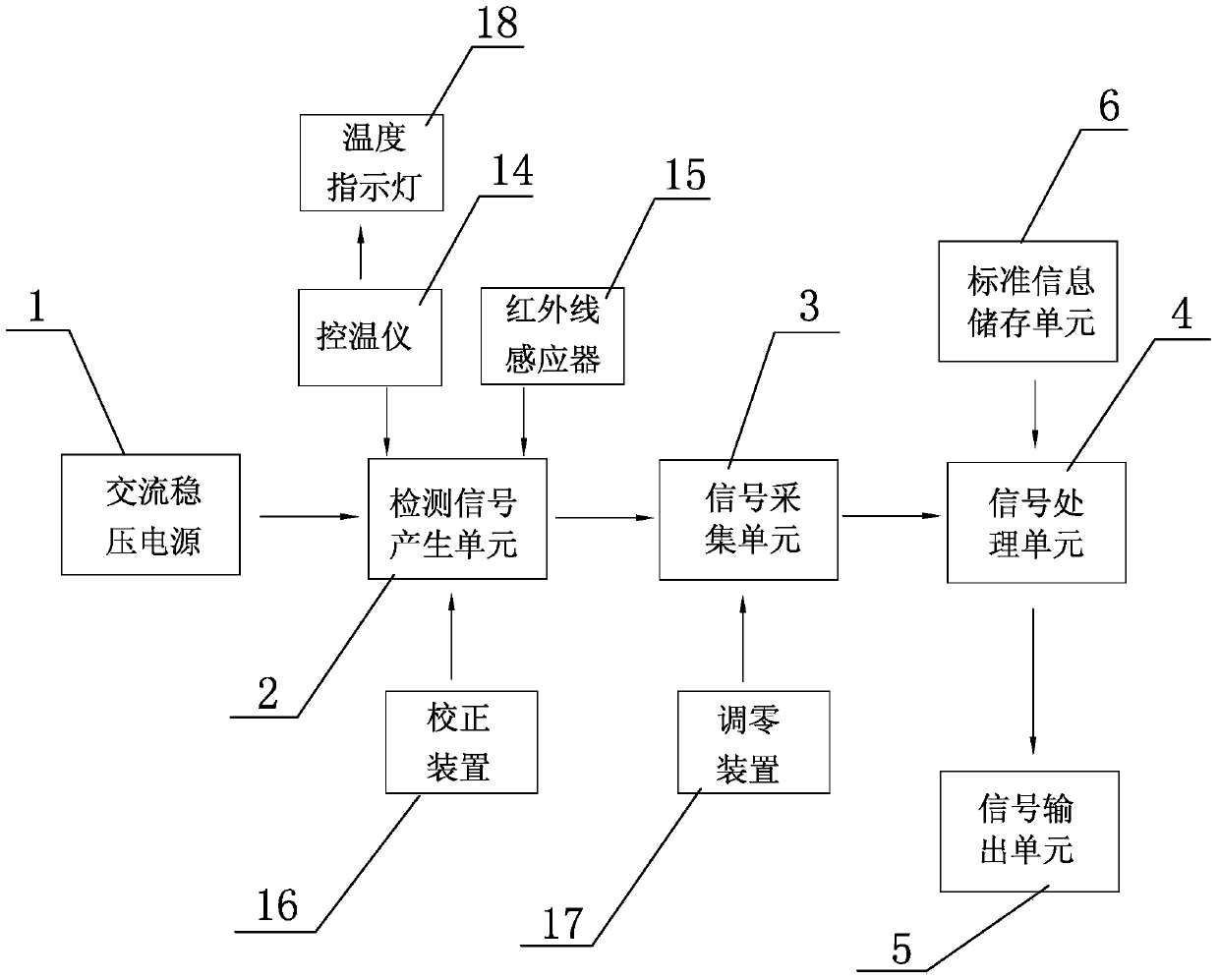

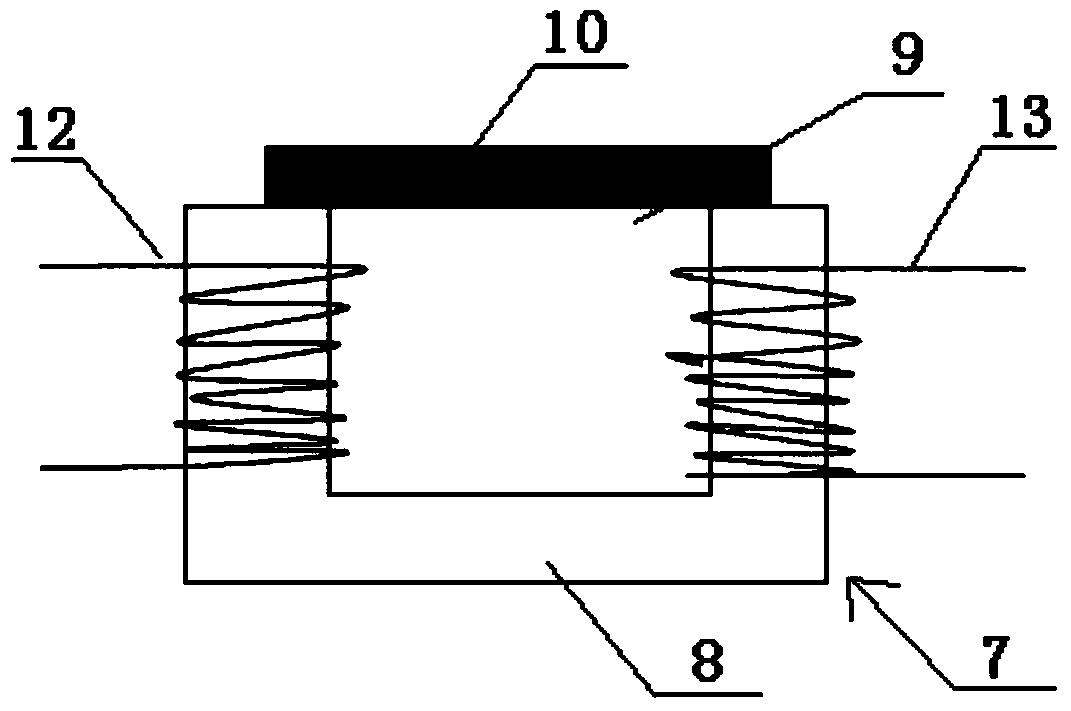

[0039] A measuring device for a rapid determination method of ferrous oxide in sintered ore, such as figure 1 As shown, it includes an AC regulated power supply 1, a detection signal generation unit 2, a signal acquisition unit 3, a signal processing unit 4 and a signal output unit 5 connected in sequence, and the signal processing unit 4 is connected with a standard information storage unit 6, such as figure 2 and image 3 As shown, the detection signal generation unit 2 includes a transformer 7, the upper end of the iron core 8 of the transformer 7 is provided with a magnetic circuit disconnection notch 9, and the magnetic circuit disconnection notch 9 is provided with a sinter sample 10 for placing the sintered ore sample to be tested and sintered to be tested. The sample measuring chamber 11 in which the ore sample 10 is in contact with the iron core 8, the primary coil 12 of the transformer 7 is connected to the AC stabilized voltage power supply 1, the secondary coil 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com