Nine-strand steel core steel wire rope online tensioning production line equipment and technology for ultra-high-speed elevators

A production line equipment, wire rope technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

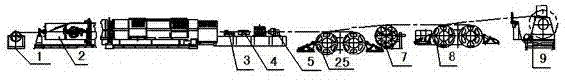

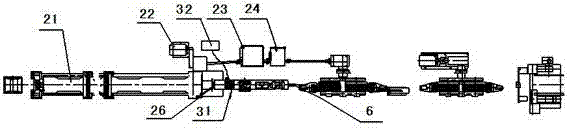

[0017] Example: To produce 9×25Fi+IWR-13.0mm ultra-high-speed elevator steel wire rope, arrange the outer strand 1×25Fi single-strand pay-off at the tail pay-off device of the tubular machine, its pay-off method, tension control method and rope twisting unit 2 strand pay-off is the same, the IWR metal rope core pay-off is arranged in the first frame of the rope twisting unit 2, to ensure the same tension, while reducing the twisting stress of the wire rope, avoiding the wire rope caused by the IWR metal rope core placing the tail of the machine And the metal core structure is destroyed. The application of this process completes the continuous production of the twisting, post-deformation, sizing, pre-tensioning and take-up of the nine-strand metal core steel wire rope at one time, which improves the production efficiency and the even distribution of the residual twisting stress of the metal core steel wire rope.

[0018] Process flow of nine-strand steel core wire rope for ultra-h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com