Preparation method of regular pentagonal prism-shaped copper micrometer wire

A technology of pentagonal prisms and micron wires, which is applied in the field of preparation of regular pentagonal prism copper micron wires, can solve problems such as difficult operation, unstable quality, and complicated methods, and achieve the effects of low cost, recyclable raw materials, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 35 ml of water into the beaker, add 3.72 g (0.01 mol) of EDTA-2Na (disodium ethylenediamine tetraacetate), add 1.6 g of copper sulfate (0.01 mol), and stir well. Then 1.4 g (0.01 mol) of urotropine and 0.8 g of CTAB (cetyltrimethylammonium bromide) were added in sequence and stirred evenly to obtain a mixed solution.

[0028] The mixed solution was placed in an autoclave for hydrothermal reaction at 150° C. for 120 hours. After the reaction, the precipitate was collected by centrifugation, washed three times with absolute ethanol, then washed three times with deionized water, and dried at 30° C. for 12 hours to obtain material 1.

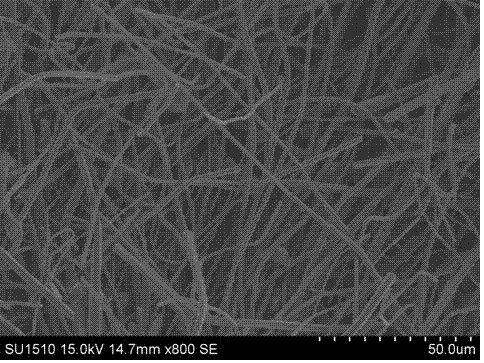

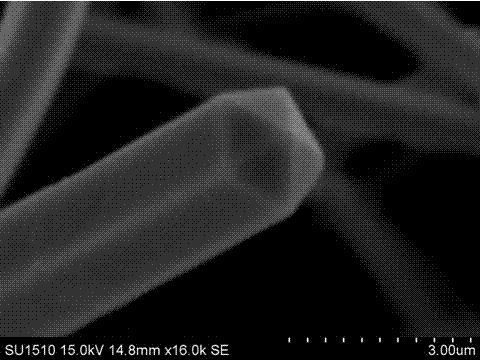

[0029] From Figure 7 It can be seen that material 1 is pure copper with extremely high crystallinity. From figure 1 It can be seen that the copper micron wire of material 1 is a regular pentagonal column structure; from figure 2 It can be seen that the length of the copper micron line of material 1 is between 200 and 300 microns, w...

Embodiment 2

[0032] Add 35 ml of water into the beaker, add 3.72 g (0.01 mol) of EDTA-2Na (disodium ethylenediamine tetraacetate), add 0.005 mol of copper nitrate, and stir well. Then 0.70 g (0.005 mol) of urotropine and 0.4 g of CTAB (cetyltrimethylammonium bromide) were added in sequence and stirred evenly to obtain a mixed solution.

[0033] The mixed solution was placed in an autoclave for hydrothermal reaction at 135° C. for 144 hours. After the reaction, the precipitate was collected by centrifugation, washed three times with absolute ethanol, then washed three times with deionized water, and dried at 80° C. for 0.5 hour to obtain material 2.

[0034] The X-ray electron diffraction image of material 2 shows that material 2 is pure copper with extremely high crystallinity. From image 3 It can be seen that the copper micron wire of material 2 is a regular pentagonal prism structure, from Figure 4 It can be seen that the length of material 2 is between 200 and 300 microns, which is...

Embodiment 3

[0038] Add 35 ml of water into the beaker, add 3.72 g (0.01 mol) of EDTA-2Na (disodium ethylenediamine tetraacetate), add 2.4 g of copper sulfate (0.015 mol), and stir well. Then 2.1 g (0.015 mol) of urotropine and 1.2 g of CTAB (cetyltrimethylammonium bromide) were added in sequence and stirred evenly to obtain a mixed solution.

[0039] The mixed solution was placed in an autoclave for hydrothermal reaction at 180° C. for 100 hours. After the reaction, the precipitate was collected by centrifugation, washed three times with absolute ethanol, then washed three times with deionized water, and dried at 55° C. for 6 hours to obtain material 3.

[0040] The X-ray electron diffraction image of material 3 shows that material 3 is pure copper with extremely high crystallinity. From Figure 6 It can be seen that the copper micron wire of material 3 is a regular pentagonal column structure, from Figure 5 It can be seen that the length of the copper micron wire is between 200 and 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com