Casting device and casting method

A crucible and gas technology, applied in stirring devices, chemical instruments and methods, self-solidification methods, etc., can solve problems such as the decline in the yield of ingots, and achieve the effect of reducing foreign matter and preventing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〉

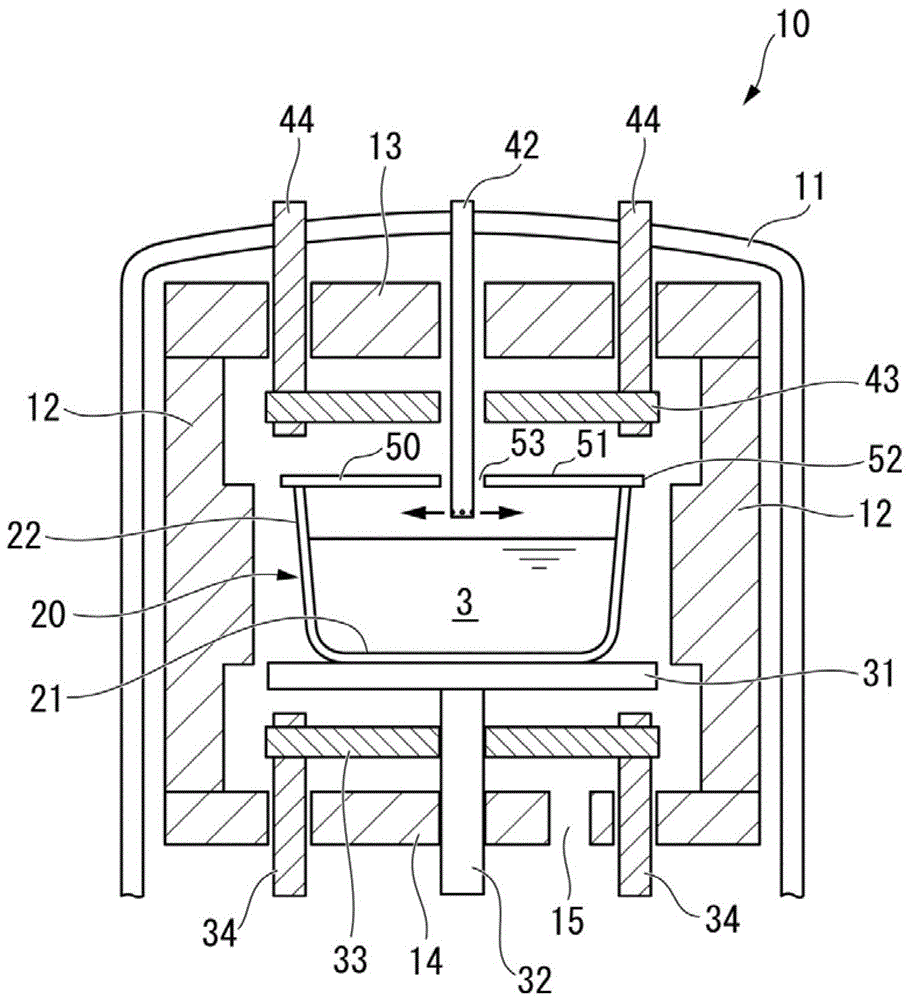

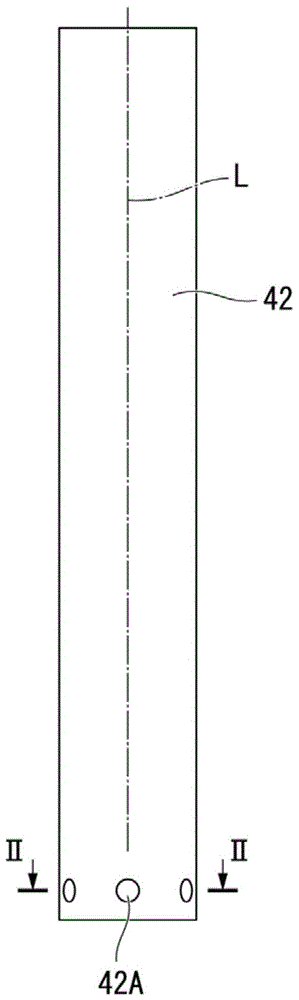

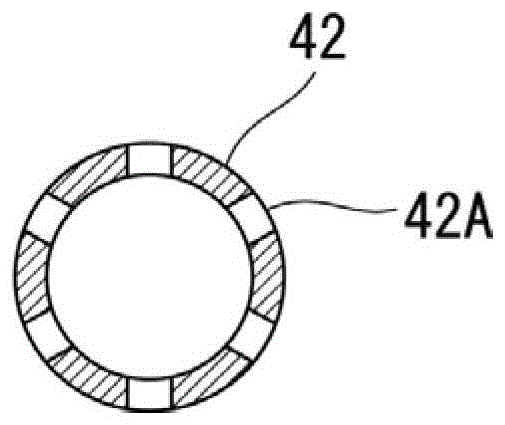

[0070] Figure 1 ~ Figure 5C The first embodiment of the casting device according to the present invention is shown. figure 1 It is a schematic cross-sectional explanatory view of the first embodiment. The casting apparatus 10 of the present embodiment includes a chamber 11 keeping the inside in an airtight state, a crucible 20 storing the silicon melt 3 , a chill plate 31 on which the crucible 20 is placed, and a The lower heater 33 , the upper heater 43 located above the crucible 20 , the cover 50 placed on the upper end of the crucible 20 , and a gas that introduces an inert gas (for example, argon) into the space between the crucible 20 and the cover 50 supply pipe 42 .

[0071] In addition, an insulating wall 12 is arranged on the outer peripheral side of the crucible 20 , an insulating top plate 13 is arranged above the upper heater 43 , and an insulating bottom plate 14 is arranged below the lower heater 33 . That is, in the casting apparatus 10 of the present embodi...

no. 2 approach 〉

[0098] Figure 6A ~ Figure 8B A second embodiment of the casting apparatus according to the present invention is shown. Figure 6A and Figure 6B It is a figure which shows the main part of 2nd Embodiment of the casting apparatus of this invention. Figure 6A is the side view of the gas channel, Figure 6B is a top view of the gas channel.

[0099] The difference between the second embodiment and the above-mentioned first embodiment is only the gas channel, and the other structures are the same as those of the first embodiment, and the description of the same parts will be omitted here.

[0100] The gas passage 60 of the second embodiment connects the base end side to the gas supply part, and includes a gas supply main pipe 61 arranged with the front end facing the upper space of the crucible, and a plurality of gas supply branch pipes branched from the front end of the gas supply pipe 61. 62.

[0101] The gas supply pipe 61 is arranged to extend in the vertical direction...

no. 3 approach >

[0111] Figure 9 , Figure 10 A third embodiment of the casting apparatus according to the present invention is shown. Figure 9 It is a perspective view which shows the main part of 3rd Embodiment of the casting apparatus of this invention.

[0112] This embodiment is also the same as the second embodiment, and the configuration other than the characteristic portion of the gas passage is the same as that of the above-mentioned first embodiment, so description thereof will be omitted.

[0113] The gas passage 70 of the third embodiment connects the base end side to the gas supply part, and includes a gas supply main pipe 71 arranged with the front end facing the upper space of the crucible, and a plurality of gas supply branch pipes 72 branched from the front end of the gas supply main pipe 71 .

[0114] The gas supply main pipe 71 is arranged to extend in the vertical direction, and is arranged to penetrate figure 1 The top plate of the chamber 11 shown passes through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com