Colored asphalt cementing material and preparation method thereof

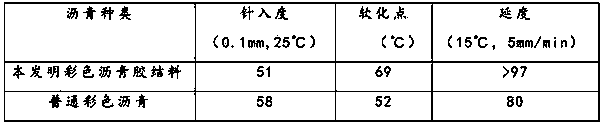

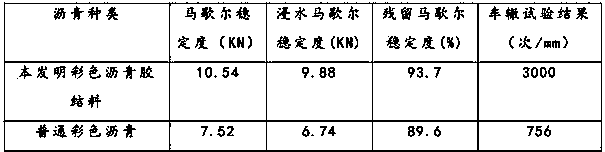

A technology of colored asphalt and binder, which is applied in the field of colored asphalt binder and its preparation, can solve the problems of insufficient high-temperature performance of colored asphalt, high cost of colored asphalt, unsatisfactory effect, etc., and achieves strong water damage resistance, simple preparation method, strong adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with specific embodiment, the present invention is described in detail as follows:

[0016] A colored asphalt binder, comprising the following raw material components by weight percentage: 10%-40% of C5 petroleum resin, 10%-40% of C9 petroleum resin, 30%-70% of rubber oil, 2%-8% of Ethylene-vinyl acetate copolymer, 2%-8% polyamide resin and 2%-8% polyurethane.

[0017] Among them, C5 petroleum resin is a fraction of cracked ethylene, which is formed by thermal polymerization or catalytic polymerization, and the average molecular weight is generally between 1000-3000. C5 petroleum resin has been widely used because of its high peel bonding strength, good fast tack, stable bonding performance and moderate melt viscosity. The most important function of C5 petroleum resin in colored asphalt is to provide adhesion, but due to the relatively small molecular weight of ordinary C5 petroleum resin, low softening point and more unsaturated hydrocarbons, resu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com