Method for deeply treating and recycling coal gasification wastewater by preposed oxidization combined with microwaves

An oxidation treatment and advanced treatment technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. , the large amount of waste water from coal-to-gas production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

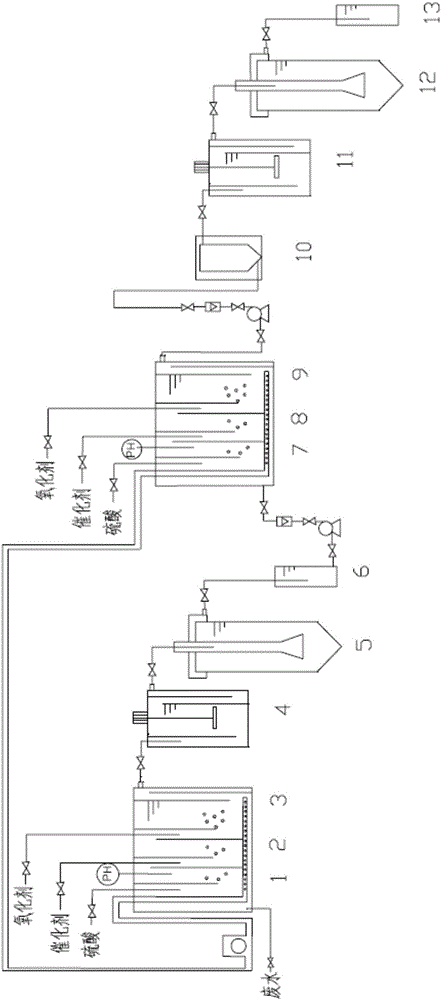

Image

Examples

Embodiment 1

[0049] The coal-gas wastewater after a certain biochemical process is treated by a method of pre-oxidation combined with microwave advanced treatment and reuse of coal-gas wastewater of the present invention. The COD of the biochemical coal gasification wastewater is 500mg / L, and the pH is 8.01. First, carry out primary acidification reaction treatment, add sulfuric acid to adjust the pH to 3.0, and react for 15 minutes. At this time, the COD of the acidified coal gasification wastewater is 350mg / L; L was catalyzed for 5 minutes, and the pH was 2.9; after primary catalysis, 350 mg / L of hydrogen peroxide was added to the wastewater after the hydrogen peroxide to wastewater ratio of 1:1, and the reaction was 80 minutes, and the pH was 2.9; the wastewater after primary oxidation Carry out flocculation reaction, add sodium hydroxide to adjust the pH of the wastewater to 9, and react for 15 minutes. At this time, the COD of the coal-gas wastewater after flocculation is 210mg / L; En...

Embodiment 2

[0051] The coal-gas wastewater after a certain biochemical process is treated by a method of the present invention which combines pre-oxidation and microwave advanced treatment of coal-gas wastewater and reuses it. The COD of the biochemical coal gasification wastewater is 450mg / L, and the pH is 8.50. First, carry out primary acidification reaction treatment, add sulfuric acid to adjust the pH to 3.3, and react for 15 minutes. At this time, the COD of the coal-gas wastewater after acidification is 320mg / L; L was catalyzed for 5 minutes, and the pH was 3.1; after primary catalysis, 320 mg / L of hydrogen peroxide was added to the wastewater after the hydrogen peroxide to wastewater ratio of 1:1, and the reaction was 80 minutes, and the pH was 3.1; the wastewater after primary oxidation Carry out flocculation reaction, add sodium hydroxide to adjust the pH of the wastewater to 8.5, and react for 10 minutes. At this time, the COD of the coal-gas wastewater after flocculation is 180...

Embodiment 3

[0053] The coal-gas wastewater after a certain biochemical process is treated by a method of the present invention which combines pre-oxidation and microwave advanced treatment of coal-gas wastewater and reuses it. The COD of the biochemical coal gasification wastewater is 550mg / L, and the pH is 8.20. First, carry out primary acidification reaction treatment, add sulfuric acid to adjust the pH to 2.5, and react for 15 minutes. At this time, the COD of the coal-gas wastewater after acidification is 400mg / L; L was catalyzed for 10 minutes, and the pH was 2.4; after primary catalysis, 600 mg / L of hydrogen peroxide was added to the wastewater after the hydrogen peroxide to wastewater ratio of 1.5:1, and the reaction was 100 minutes, and the pH was 2.4; the wastewater after primary oxidation Carry out flocculation reaction, add sodium hydroxide to adjust the pH of the wastewater to 9, and react for 15 minutes. At this time, the COD of the coal-gas wastewater after flocculation is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com