Preparing method for embellish titanium dioxide nanotube array electrode material embellished by cadmium selenide nano-particles

A nanotube array and nanoparticle technology, which can be used in electrode manufacturing, active material electrodes, hybrid capacitor electrodes, etc., can solve the problems of high photogenerated electron-hole pair recombination rate, narrow light absorption wavelength range, and low photocatalytic activity. , to achieve the effect of good photocatalytic and photoelectric catalytic performance, strong binding force and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

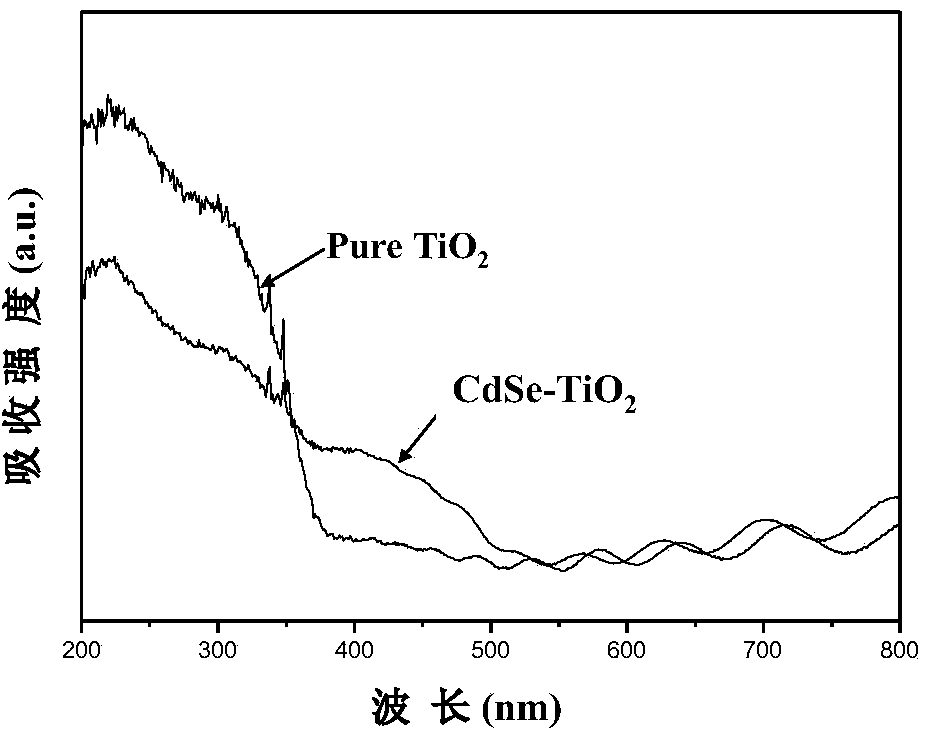

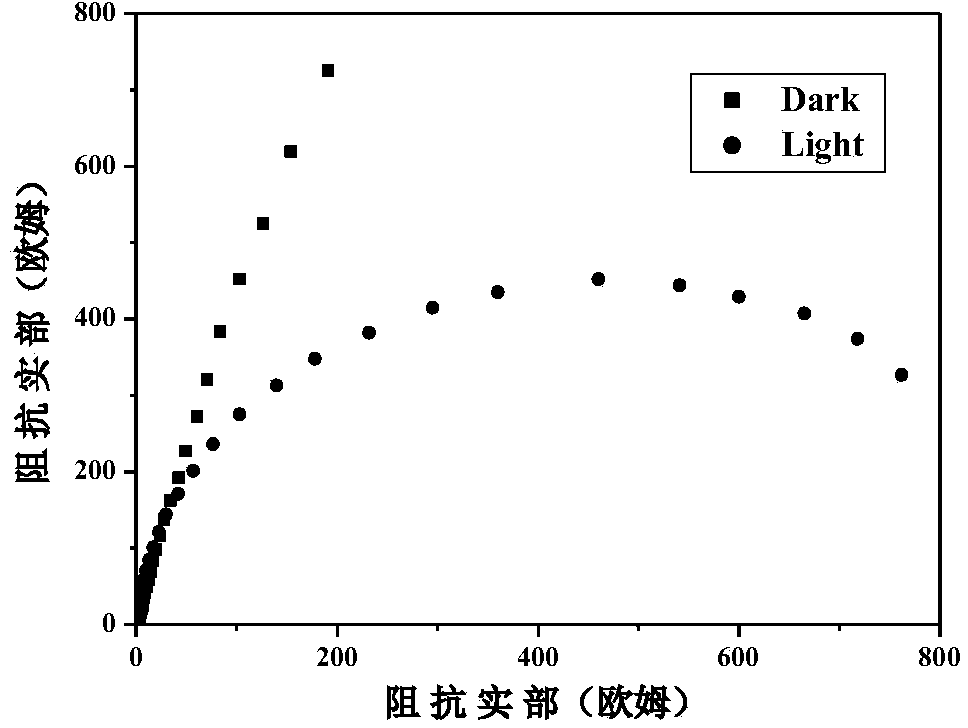

[0030] Cut the 0.3mm thick pure titanium foil into 33.0mm × 20.0mm × 0.3mm sheets, and ultrasonically clean them in acetone and ethanol in turn to remove the soluble organic matter on the surface, and then ultrasonically clean them with deionized water. Dry overnight at room temperature; apply 10V voltage, at 0.4mol / L NH 4 F. 0.4mol / L H 3 PO 4 Nanotube arrays can be obtained after anodic oxidation for 10 hours; the nanotube arrays are rinsed with deionized water, and then placed in deionized water for ultrasonic cleaning for 5 minutes, then taken out and dried at 500 °C, 2 °C / Min conditions, calcination for 2 h to obtain anatase phase of titanium dioxide nanotube arrays. Then, the obtained nanotube array electrode was used as the working electrode, the platinum sheet was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode. Nano metal particles Cd were deposited on the surface of the TiO2 nanotube array and the inner wall ...

Embodiment 2

[0032] Cut the 0.3mm thick pure titanium foil into 33.0mm × 20.0mm × 0.3mm sheets, and ultrasonically clean them in acetone and ethanol in turn to remove the soluble organic matter on the surface, and then ultrasonically clean them with deionized water. Dry overnight at room temperature; apply 20V voltage, at 0.2mol / L NH 4 F. 0.2mol / L H 3 PO 4In the aqueous solution, nanotube arrays can be obtained after anodizing for 8 hours; the nanotube arrays are rinsed with deionized water, ultrasonically cleaned in deionized water for 2 minutes, taken out and dried, and dried at 500°C, 2°C / Under the condition of min, calcined for 2h to get titanium dioxide nanotube arrays in anatase phase. Then, the obtained nanotube array electrode was used as the working electrode, the platinum sheet was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode. A bias voltage of -1.0V was applied to the working electrode by the constant potential deposit...

Embodiment 3

[0034] Cut the pure titanium foil with a thickness of 0.3mm into a sheet of 33.0mm×20.0mm×0.3mm, ultrasonically clean it in acetone and ethanol in turn to remove soluble organic matter on the surface, and then ultrasonically clean it with deionized water. Dry overnight at room temperature; apply 20V voltage, in 0.2mol / L NH 4 F, 0.1mol / L H 3 PO 4 In the aqueous solution, nanotube arrays can be obtained after anodizing for 7 hours; the nanotube arrays are rinsed with deionized water, ultrasonically cleaned in deionized water for 1 min, taken out and dried, and dried at 500 °C, 2 °C / Under the condition of min, calcined for 2h to get titanium dioxide nanotube arrays in anatase phase. Then, the obtained nanotube array electrode was used as the working electrode, the platinum sheet was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode. A bias voltage of -2.0V was applied to the working electrode by the constant potential deposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com