Regeneration-type variable-porosity heat regenerator for low temperature refrigerator

A low-temperature refrigerator and porosity technology, applied in refrigerators, superheaters, refrigeration components, etc., can solve the problems of increasing the loss of the regenerator and the unfavorable efficiency of the regenerator, so as to improve the heat recovery efficiency, reduce the internal loss, increase the The effect of cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

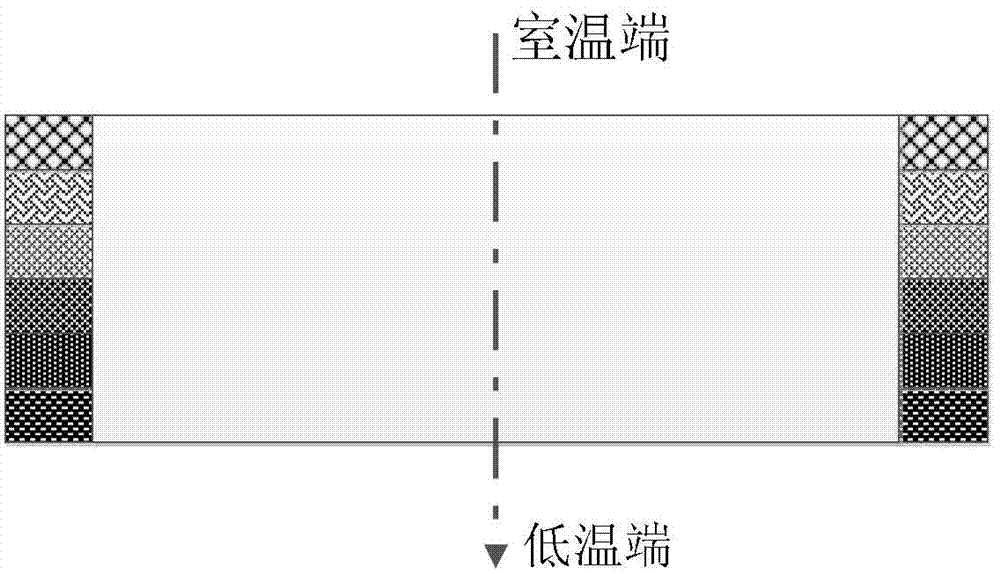

[0026] refer to figure 2 , figure 2 It is a cross-sectional structure diagram of a variable porosity regenerator for a cylindrical regenerative cryogenic refrigerator. The regenerator includes a low-temperature section and a high-temperature section. The regenerator is filled with multiple layers of regenerative fillers with different porosities. The hydraulic diameter range of the regenerative fillers is 20-30 μm. The regenerative fillers are stainless steel wire mesh. The number range is 400-635. It can be seen from the figure that the regenerator is filled with 6 layers of regenerative fillers, and the porosity of the regenerative fillers gradually decreases from the room temperature end to the low temperature end. The room temperature end shown in the figure is the hot end of the high temperature section, and the low temperature end is the cold end of the low temperature section. For example, a single-stage Stirling-type pulse tube refrigerator used in a temperature r...

Embodiment 2

[0031] refer to image 3 , image 3 It is a cross-sectional structure diagram of a variable porosity regenerator for a ring-shaped regenerative cryogenic refrigerator. The regenerator includes a low-temperature section and a high-temperature section. The regenerator is filled with multiple layers of regenerative fillers with different porosities. The hydraulic diameter of the regenerative fillers ranges from 10-25 μm. It can be seen from the figure that the regenerator is filled with 6 layers of regenerating fillers. From the room temperature end to the low temperature end, the porosity of the regenerating fillers gradually decreases. The porosity range of the regenerating fillers filled in the regenerator is 59%-92%, the room temperature end shown in the figure is the hot end of the high temperature section, and the low temperature end is the cold end of the low temperature section.

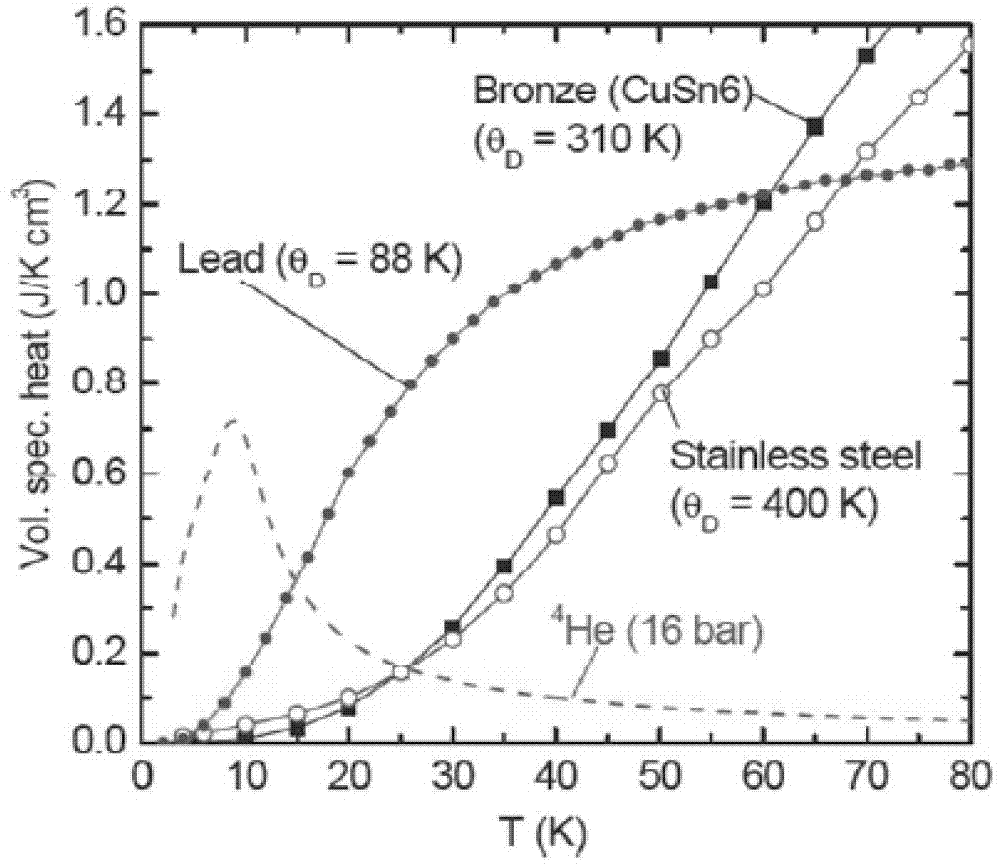

[0032] The influence of the variable porosity of the regenerative filler on the refrigerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com