Bidirectional diffusion centrifugal fan

A technology of centrifugal fan and centrifugal impeller, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve problems such as not meeting the requirements, and achieve the effect of compact structure, reliable guarantee, and improved noise index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

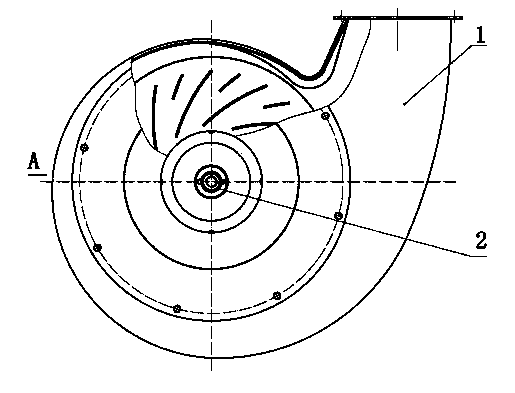

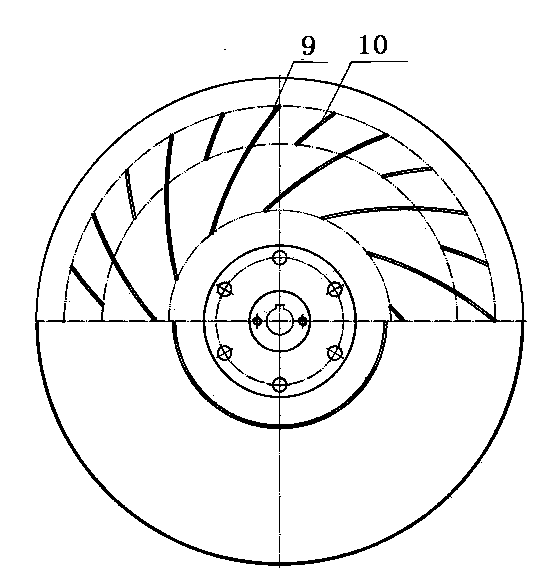

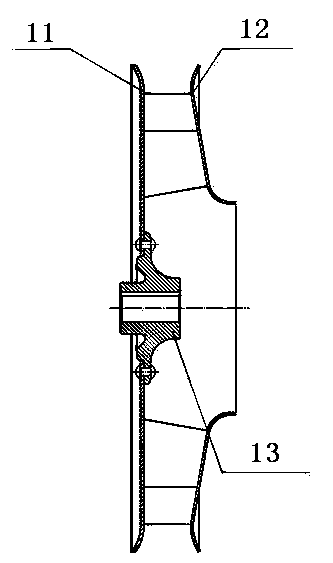

[0021] Referring to the above drawings, a two-way diffuser centrifugal fan includes a volute assembly 1, a shaft head stopper 2, an impeller assembly 3, an air inlet collector 4, a mounting frame (5), a shock pad 6, The motor 7 and the junction box device 8 are characterized in that the impeller assembly 3 is a centrifugal impeller assembly with two-way diffuser and long and short blade structure, and the centrifugal impeller assembly 3 is fixed on the shaft extension end of the motor 7 through the shaft end stopper 2 ; Centrifugal impeller assembly 3 includes blades, rear disc 11, front disc 12 and hub 13;

[0022] Described blade is provided with the blade of two kinds of specifications, namely long blade 9 and short blade 10, and the quantity of long blade 9 and short blade 10 is equal, and ratio is 1:1; The length ratio of long blade 9 and short blade 10 is 3 :1, the long blades 9 and the short blades 10 are evenly distributed and staggered at 1:1 and welded between the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com