A Dielectrophoresis Automobile Exhaust Dust Collector

A technology of dielectrophoresis and dust collector, which is applied in the direction of exhaust equipment, climate change adaptation, climate sustainability, etc., to achieve the effects of reducing pollution, improving exhaust emission standards, and strong dielectrophoresis force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below through the accompanying drawings and specific examples, but the present invention is not limited to the following embodiments, and any changes or alternatives made on the principle of this example all fall within the scope of the present invention. among.

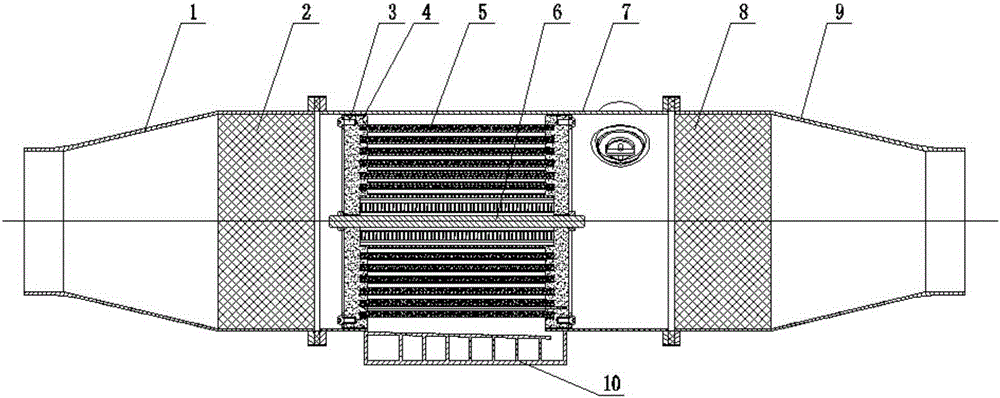

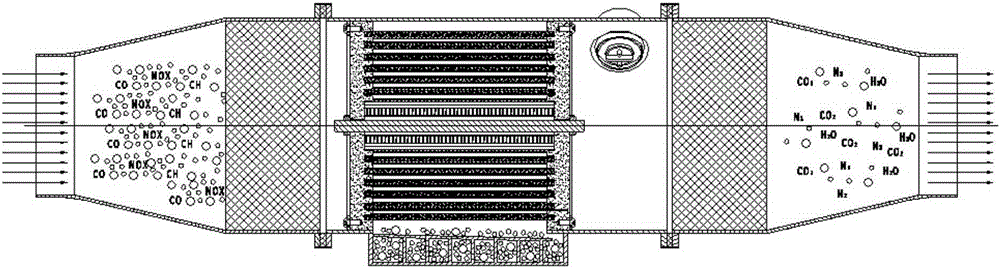

[0020] A kind of dielectrophoresis tail gas dust collector, such as figure 1 As shown, it includes a processing cylinder 7, an air intake cylinder 1, an outlet cylinder 9 and an electrode 5, a front end three-way catalytic converter 2, and a rear end three-way catalytic converter 8. The outlet cylinder is coaxially fixed with the front-end three-way catalytic converter and the rear-end three-way catalytic converter in the air inlet cylinder and the outlet cylinder respectively, and ceramic flanges 4 are coaxially mirrored and symmetrically fixed on both sides of the processing cylinder respectively. Each of the ceramic flanges is fixed on the mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com