Horizontal elastic damping system for long-span bridges

A technology of horizontal elasticity and damping system, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of collision between main beam and adjacent span approach bridge, loss of structural integrity, inability to reset, etc., to avoid excessive horizontal displacement, The effect of improving anti-shock performance and simple structure

Active Publication Date: 2016-02-03

CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Under the action of live loads such as temperature, wind load, and vehicle load, the beam end will produce a large horizontal displacement, and the horizontal displacement of the bridge under the above load cannot be reset because there is no horizontal elastic damping system, and the beam end is too large. The displacement may cause the collision between the main girder and the adjacent approach bridge, the falling girder of the main girder, and the collision with the anchor pier, etc., which will cause the loss of integrity of the entire structure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

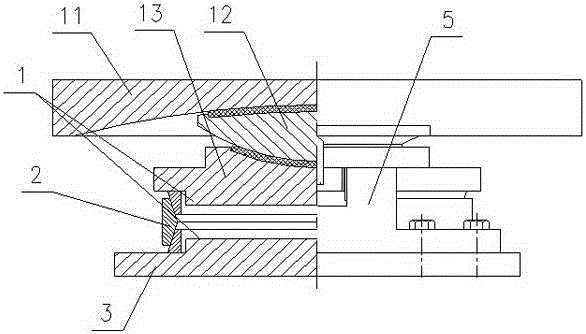

[0030] see Figure 5 The difference between this embodiment and Embodiment 1 is that a guide groove 14 is provided in the middle of the bottom of the lower seat plate 13, and a guide column 15 is correspondingly provided on the base 3, and the guide column 15 is slidingly fitted with the guide groove 14.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

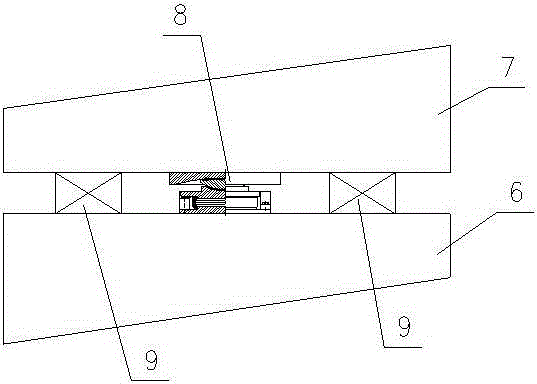

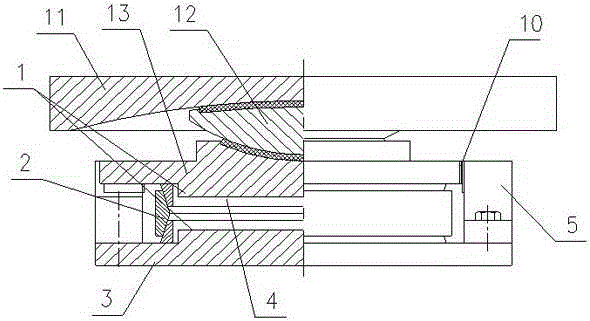

The invention discloses a horizontal elastic damping system of a long-span bridge. The horizontal elastic damping system comprises an elastic seismic-reduction support and common supports, wherein the elastic seismic-reduction support and the common supports are installed between an abutment and a bridge body. Two sides of the elastic seismic-reduction support are provided with the common supports, and the elastic seismic-reduction support mainly consists of an upper support plate, a middle lining plate, a lower support plate and a base. The middle lining plate is assembled between the upper support plate and the lower support plate and forms a curved surface slide fitting surface with the upper support plate and the lower support plate, the base is located under the lower support plate, and a vertical spring is arranged between the lower support plate and the base. The horizontal elastic damping system is simple in structure and reasonable in design, can convert horizontal force suffered by the bridge body into vertical force and convert horizontal damping rigidity of the bridge body into vertical damping rigidity, avoids overlarge horizontal displacement of the bridge body, accordingly limits the horizontal displacement of the bridge effectively, has energy-dissipation and seismic-reduction effects on seismic load and improves the seismic resistance and reduction performance of the bridge.

Description

technical field [0001] The invention relates to a damping system, in particular to a horizontal elastic damping system of a long-span bridge. Background technique [0002] At present, in order to prevent possible earthquake disasters, it is necessary to carry out seismic design of bridges. In the transverse bridge direction of the cable-stayed bridge, the main girder and the main tower generally use wind-resistant bearings to restrict the relative movement of the beam and the tower, and the tops of the anchor piers and auxiliary piers are often equipped with lateral limit devices, which will cause earthquakes. The inertial force transmitted to the pier column is too large, so the side pier and its foundation of the cable-stayed bridge are the weak parts of seismic resistance in the transverse bridge direction. For general cable-stayed bridges, the anchor piers and auxiliary piers can allow the bridge pier columns to enter the plastic state under strong earthquakes, and the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E01D19/04

Inventor 宋辉熊劲松黄李骥刘海亮邹贻军

Owner CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com