The construction method of the separated seismic isolation support system for the bridge pier

A support system and construction method technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as structural damage of structural objects, and achieve the effects of reducing destructive force, reasonable design, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

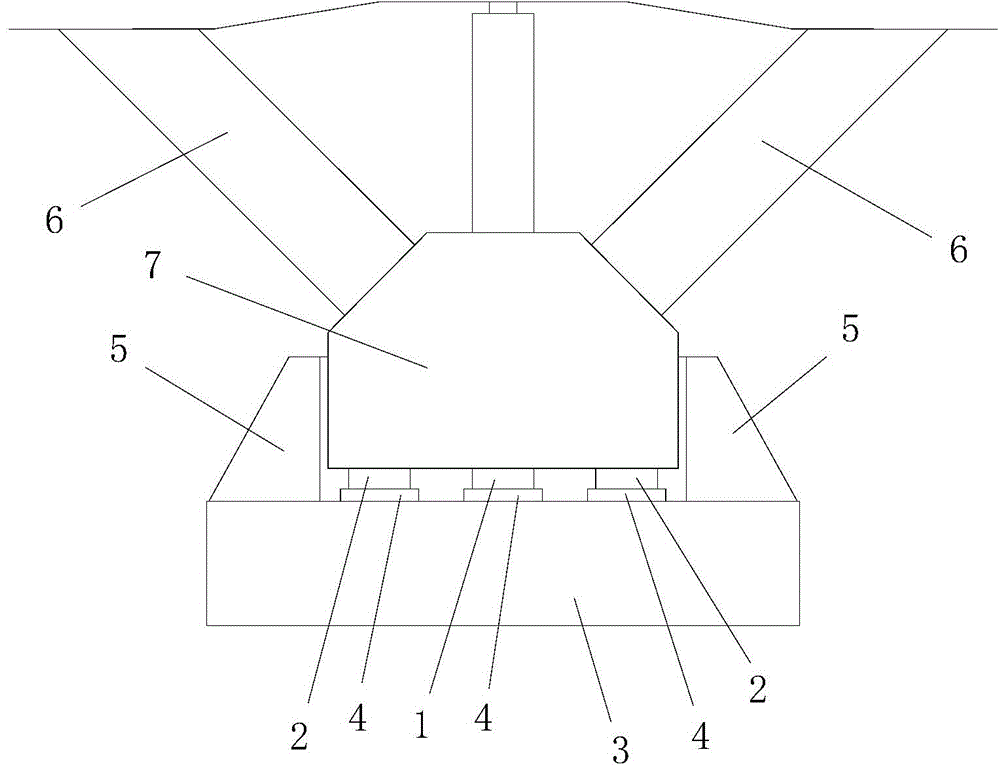

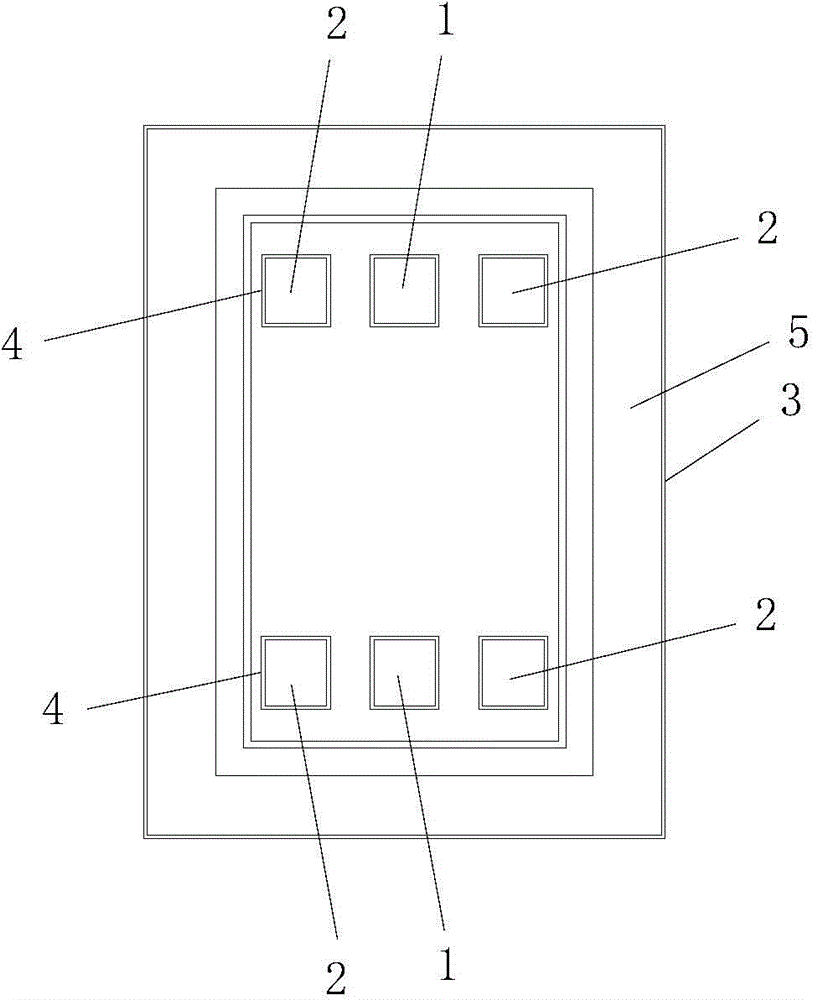

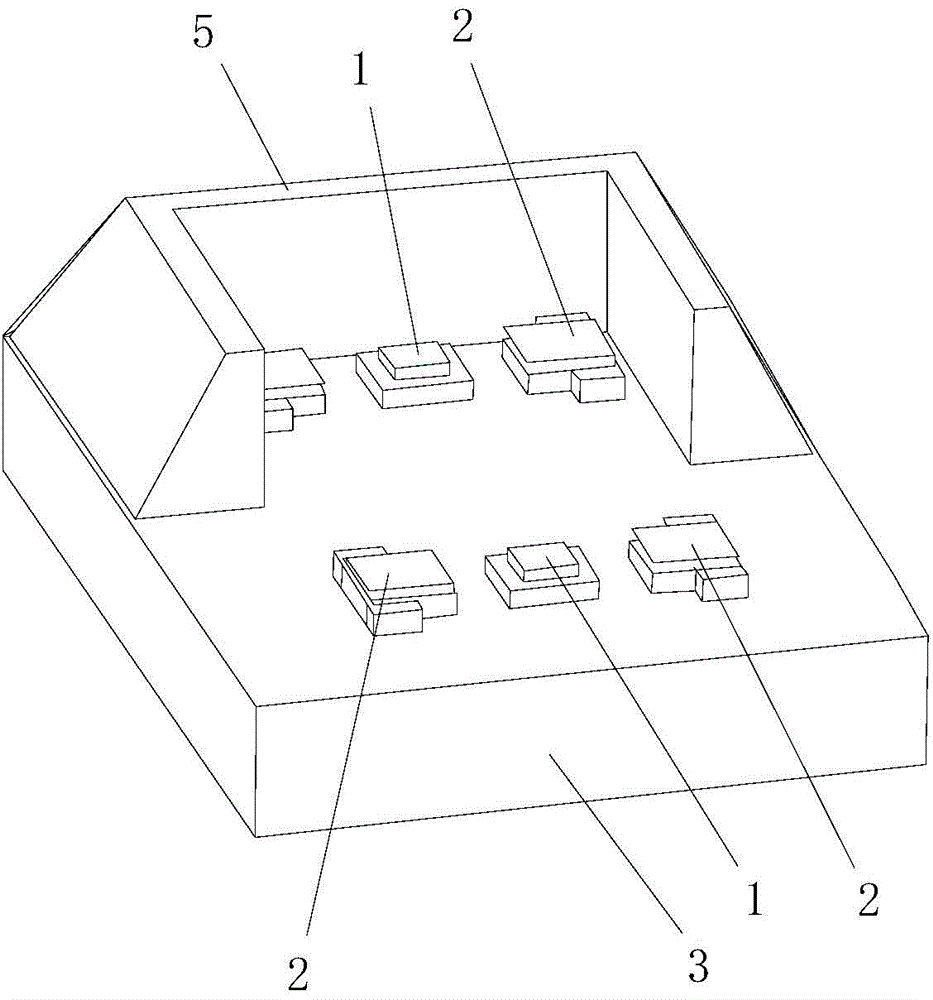

[0044] Such as figure 1 , figure 2 , image 3 and Figure 4 A separate shock-absorbing and isolating support system for bridge piers is shown, which includes two rows of supports arranged on the piers of the bridge under construction along the longitudinal direction of the bridge, and the two rows of supports are arranged symmetrically. Each row of bearings includes a basin-type rubber bearing 1 and two lead core vibration-isolation rubber bearings 2 symmetrically arranged on the left and right sides of the basin-type rubber bearing 1 . The cap 3 on the top of the pier is provided with six support pads 4 for the installation of the basin rubber bearing 1 and the lead core isolation rubber bearing 2 respectively, and the basin rubber bearing 1 and the lead core isolation rubber bearing A grouting layer 8 is arranged between the vibration rubber bearing 2 and the bearing pad 4 .

[0045] In this embodiment, the construction bridge is a two-span semi-intermediately supported...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com