Rubber vibration isolation pad

A rubber vibration isolation pad, vibration isolation pad technology, applied in the field of vibration isolation and vibration reduction, to achieve good compression and vibration isolation performance, reduce resistance and wear, good ventilation and drainage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

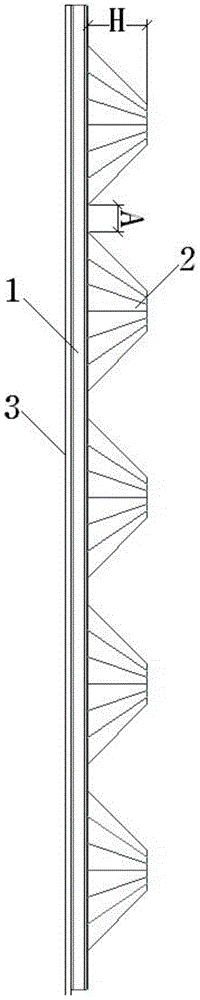

[0026] see figure 1 , figure 2 As shown, a preferred embodiment of the rubber vibration isolation pad of the present invention is shown.

[0027] The vibration isolation pad at least includes a surface layer 1 and a plurality of conical protrusions 2, and the rubber vibration isolation pad can effectively perform vibration isolation and noise reduction by being installed under concrete track slabs and other load-bearing structures.

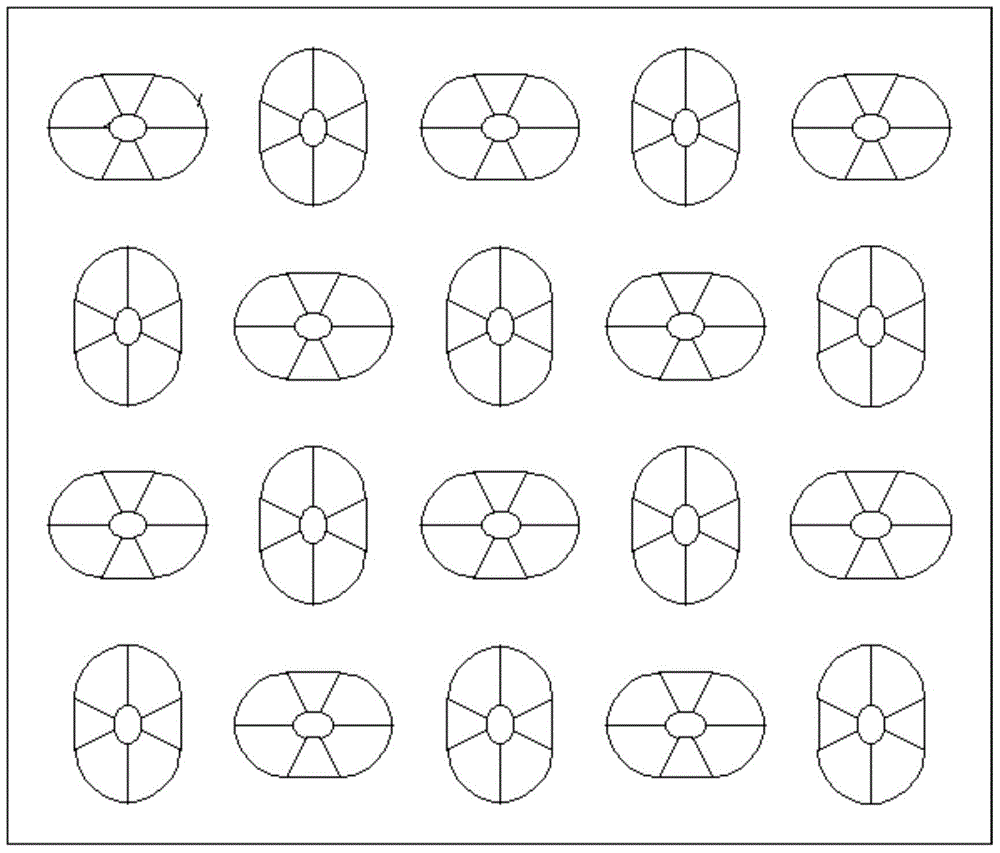

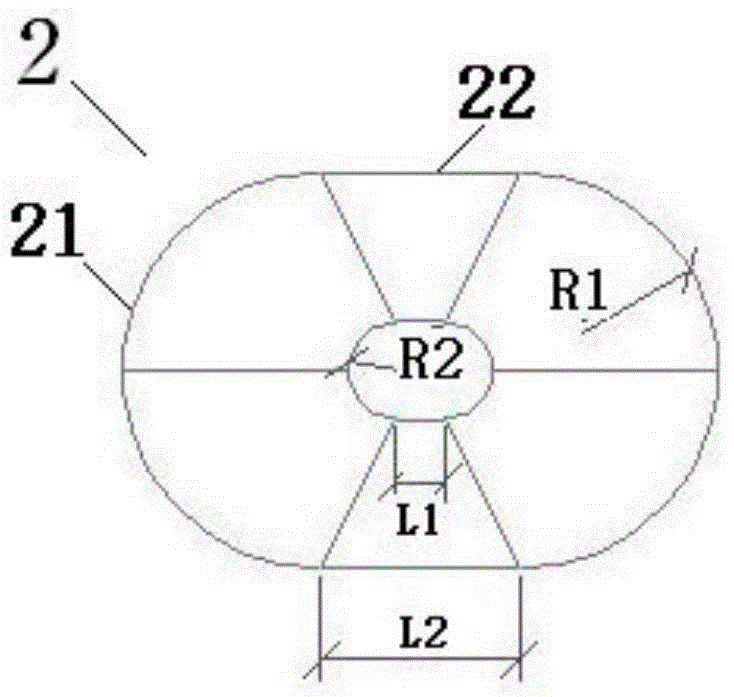

[0028] Wherein, the plurality of conical protrusions 2 are arranged on one side surface of the surface layer 1 in an array, and the conical protrusions 2 are spaced apart from each other by a certain distance. In order to form a better vibration isolation effect, the conical protrusions 2 adopt a special shape, image 3 It is a structural schematic diagram of the frustum of a cone 2 according to the present invention. The frustum of a cone 2 is a symmetrical key-shaped body whose cross-section is composed of two semicircles 21 and two straight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com