Engine noise reduction component vibration damping installation device

A technology for installing devices and engines, which is applied in the direction of engine components, power devices, noise reduction devices, etc., can solve the problems of rubber suspension abnormal noise, wear deformation, axial movement, etc., to improve service life, reduce vibration, strong The effect of fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

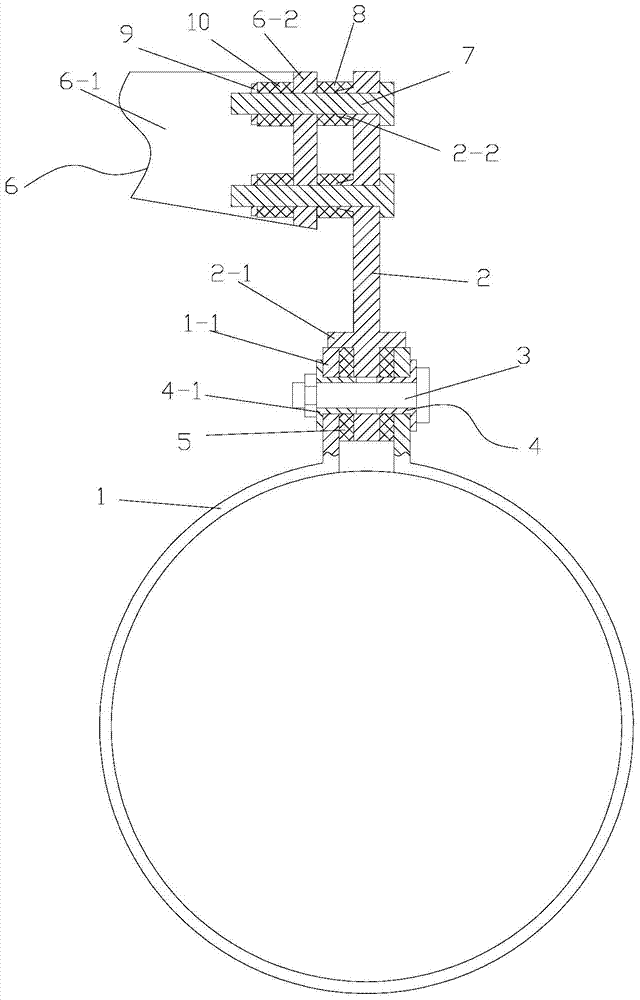

[0014] figure 1 It is a schematic diagram of the structure of the present invention, as shown in the figure: the vibration damping installation device of the engine noise reduction component of the present embodiment includes a vehicle body connecting plate 6, a muffler hoop 1 and a suspension arm 2, and also includes fixing the upper end of the suspension arm 2 to the vehicle body. The upper connection assembly of the vertical side plate of the plate 6, the upper connection assembly is provided with at least one set, and each set of upper connection assemblies includes an upper connection piece 7 and a vertical side plate and a suspension arm arranged on the vehicle body connection plate 6 2 is used for vibration reduction and the first shock absorber 8 passed by the upper connecting piece 7; wherein, the body connection plate 6 is fixedly connected with the body of the car, the muffler hoop 1 is used to fix the muffler, and the suspension arm 2 is used for Connect the body c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com