Water-based composite exterior wall coating and preparing method thereof

A water-based technology for exterior wall coatings, applied in coatings, etc., can solve problems such as high temperature resistance, weather resistance, water resistance, poor adhesion and environmental protection, etc., and achieve the effect of huge market demand, good application prospects, and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

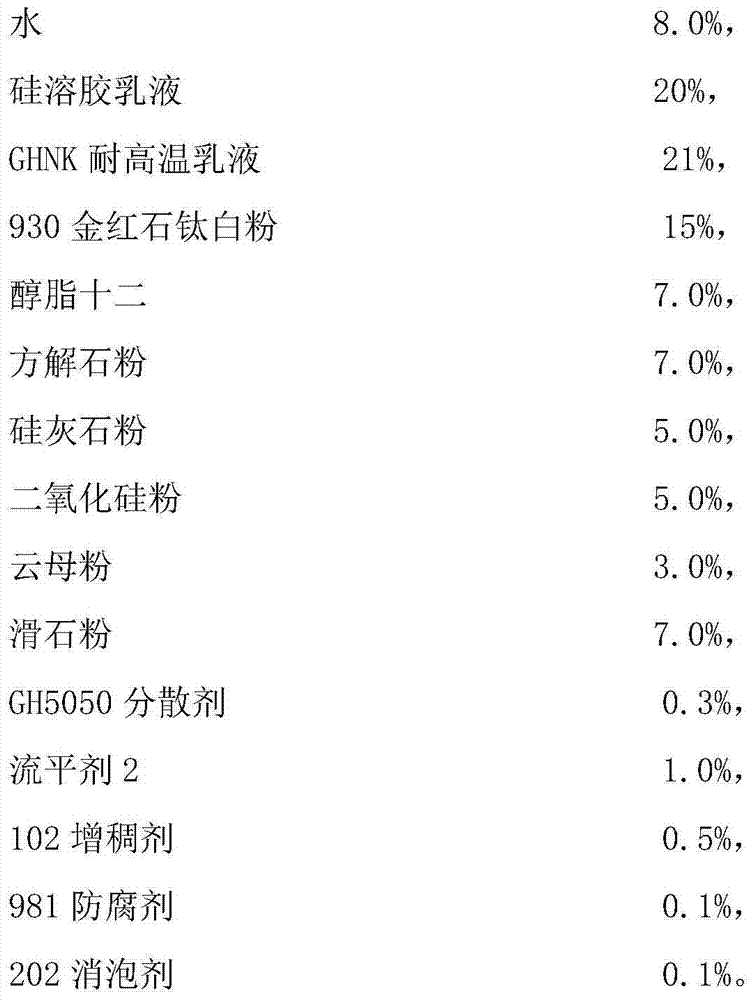

[0011] 1. The mass percentage content of each component of the coating is:

[0012]

[0013] The particle size of the calcite powder, wollastonite powder, silicon dioxide powder, mica powder and talc powder is all 1000.

[0014] Two, the preparation method is:

[0015] According to the formula, first add water to the container of the mixer, start the mixer at a speed of 1500rP / min, add 930 rutile titanium dioxide, calcite powder, wollastonite powder and stir for 19-23 minutes; add silica sol emulsion and stir for 19-23 minutes After 10 minutes, add silica powder, mica powder and talcum powder respectively and continue to stir for 19-23 minutes, then add GHNK high temperature resistant emulsion and continue to stir for 19-23 minutes, then add alcohol fat twelve and stir for 29-33 minutes, and finally add GH5050 dispersant, leveling agent 2, 102 thickener, 981 preservative, and 202 defoamer continue to stir for 39-43 minutes, filter and pack into barrels to obtain a water-ba...

Embodiment 2

[0020] 1. The mass percentage content of each component of the coating is:

[0021]

[0022] The particle size of the calcite powder, wollastonite powder, silicon dioxide powder, mica powder and talc powder is all 1200 mesh.

[0023] Two, preparation method is with embodiment 1.

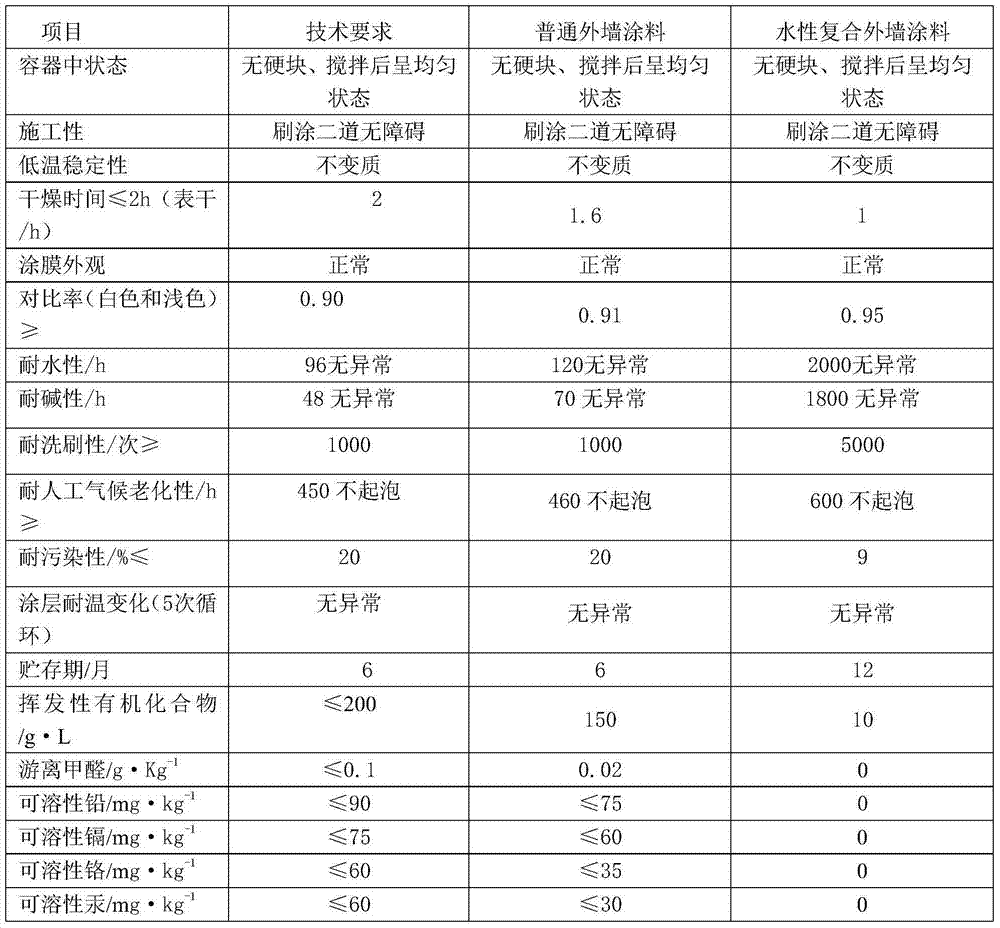

[0024] Three, the beneficial effects of this embodiment (compared with the prior art) are as follows in Table 2:

[0025] Table 2 Common Exterior Wall Paint and Example 2 Exterior Wall Paint Conventional Performance Test Comparison

[0026]

[0027]

Embodiment 3

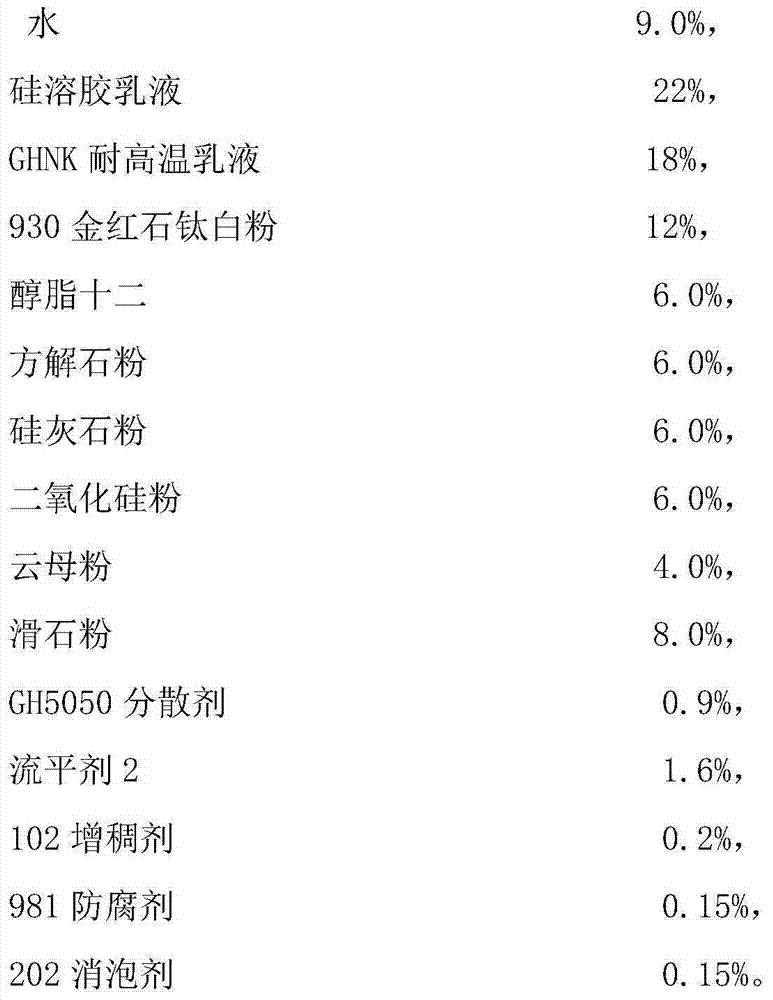

[0029] 1. The mass percentage content of each component of the coating is:

[0030]

[0031] The particle size of the calcite powder, wollastonite powder, silicon dioxide powder, mica powder and talc powder is all 1300 mesh.

[0032] Two, preparation method is with embodiment 1.

[0033] Three, the beneficial effects of this embodiment (compared with the prior art) are as follows in Table 3:

[0034] Table 3 Common Exterior Wall Paint and Example 3 Exterior Wall Paint Conventional Performance Test Comparison

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com