Preparation method of mangosteen shell natural dye, application and staining method thereof

A technology for natural dyes and mangosteen shells, applied to natural dyes and their application fields, can solve the problems of poor extraction efficiency, long time consumption, and no reports, and achieves short time, low price, and good ecological environment compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

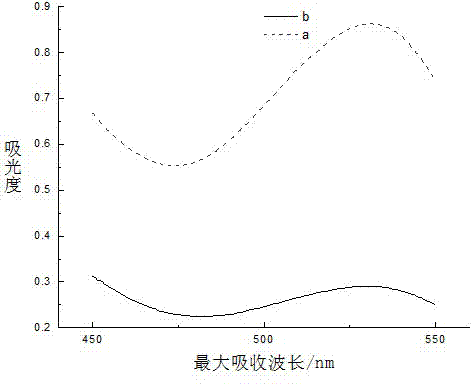

Image

Examples

Embodiment 1

[0022] Wash the mangosteen shell, dry it in the air, and crush it mechanically. Weigh 1 kg of the crushed mangosteen shell and add it to 10 kg of ethanol aqueous solution containing sodium hydroxide, and extract at 90°C for 30 minutes to obtain the extract. Wherein, the mass percent concentration of the ethanol aqueous solution is 20%, and every kilogram of ethanol aqueous solution contains 0.5 grams of sodium hydroxide. Then, the extract is filtered and concentrated to 5 kg by distillation under reduced pressure to obtain the concentrated natural dye of mangosteen shell.

Embodiment 2

[0024] Wash the mangosteen shell, dry it in the air, and crush it mechanically. Weigh 1 kg of the crushed mangosteen shell and add it to 20 kg of ethanol aqueous solution containing sodium hydroxide, and extract at 75°C for 70 minutes to obtain the extract. Wherein, the mass percent concentration of ethanol aqueous solution is 30%, and every kilogram of ethanol aqueous solution contains 1 gram of sodium hydroxide. Then the extract was filtered and concentrated to 5 kg by distillation under reduced pressure to obtain the concentrated mangosteen husk natural dye.

Embodiment 3

[0026] Wash the mangosteen shell, dry it in the air, and crush it mechanically. Weigh 1 kg of the crushed mangosteen shell and add it to 30 kg of ethanol aqueous solution containing sodium hydroxide, and extract at 60°C for 120 minutes to obtain the extract. Wherein, the mass percent concentration of the ethanol aqueous solution is 40%, and every kilogram of ethanol aqueous solution contains 1.5 grams of sodium hydroxide. Then the extract was filtered and concentrated to 5 kg by distillation under reduced pressure to obtain the concentrated mangosteen husk natural dye.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com