Process for producing borneol by adopting alpha-pinene

A technology of borneol and pinene, which is applied in the technical field of producing borneol from α-pinene, can solve the problems of difficult control of temperature control requirements, violent reaction heat release, fire, etc., to avoid the explosion factor of punching materials, high purity, and dangerous Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

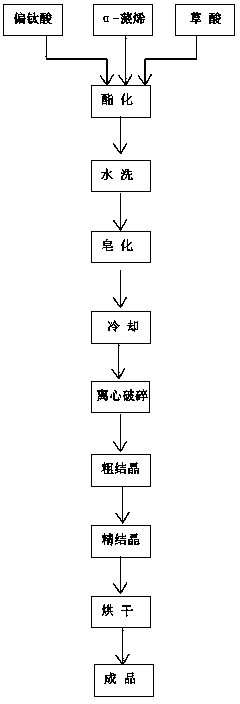

[0029] like figure 1 Shown, the technique of producing borneol with α-pinene adopts the following steps to carry out:

[0030] ① Esterification: Put α-pinene into the esterification reaction kettle, start stirring, add anhydrous oxalic acid 0.2 times the mass of α-pinene under stirring, after adding anhydrous oxalic acid, add α-pinene For the catalyst with a mass of 0.03 times, after the esterification reaction is completed, the cooling circulating water is turned on to lower the temperature in the kettle to below 70°C, the esterification reaction kettle is kept in a stirring state, and the reaction solution is transported to the water washing pot through the pipeline for washing. The catalyst is metatitanic acid.

[0031] ②Water washing: add waste acid water to the water washing pot containing the esterification reaction liquid, the amount of waste acid water added is 1.5-2 times the weight of the reaction liquid; first pass steam to heat the liquid in the pot to 88-90 °C, ...

Embodiment 2

[0048] like figure 1 Shown, the technique of producing borneol with α-pinene adopts the following steps to carry out:

[0049] ①Esterification: Put α-pinene into the esterification reaction kettle, start stirring, add anhydrous oxalic acid 0.1 times the mass of α-pinene under stirring, after adding anhydrous oxalic acid, add α-pinene For the catalyst with a mass of 0.02 times, after the esterification reaction is completed, the cooling circulating water is turned on to lower the temperature in the kettle to below 70°C, the esterification reaction kettle is kept in a stirring state, and the reaction solution is transported to the water washing pot through the pipeline for washing.

[0050] The catalyst is metatitanic acid, which is prepared by the following method: a. Mix the titanium white slurry with water, add NaOH solution with a concentration of 30%, and adjust the pH value to 8-9; then add water and wash repeatedly 2-5 times , during which the pH value is maintained at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com