Method and device for preparing titanium solution from fluidized acidolysis titanium-containing material

A fluidization and acidolysis solution technology, applied in the direction of titanium oxide/hydroxide, titanium dioxide, etc., can solve the problems of limited sulfuric acid titanium dioxide production, early hydrolysis of titanium solution, long reaction time, etc., to achieve low cost, Saving dosage, good effect of fluidization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

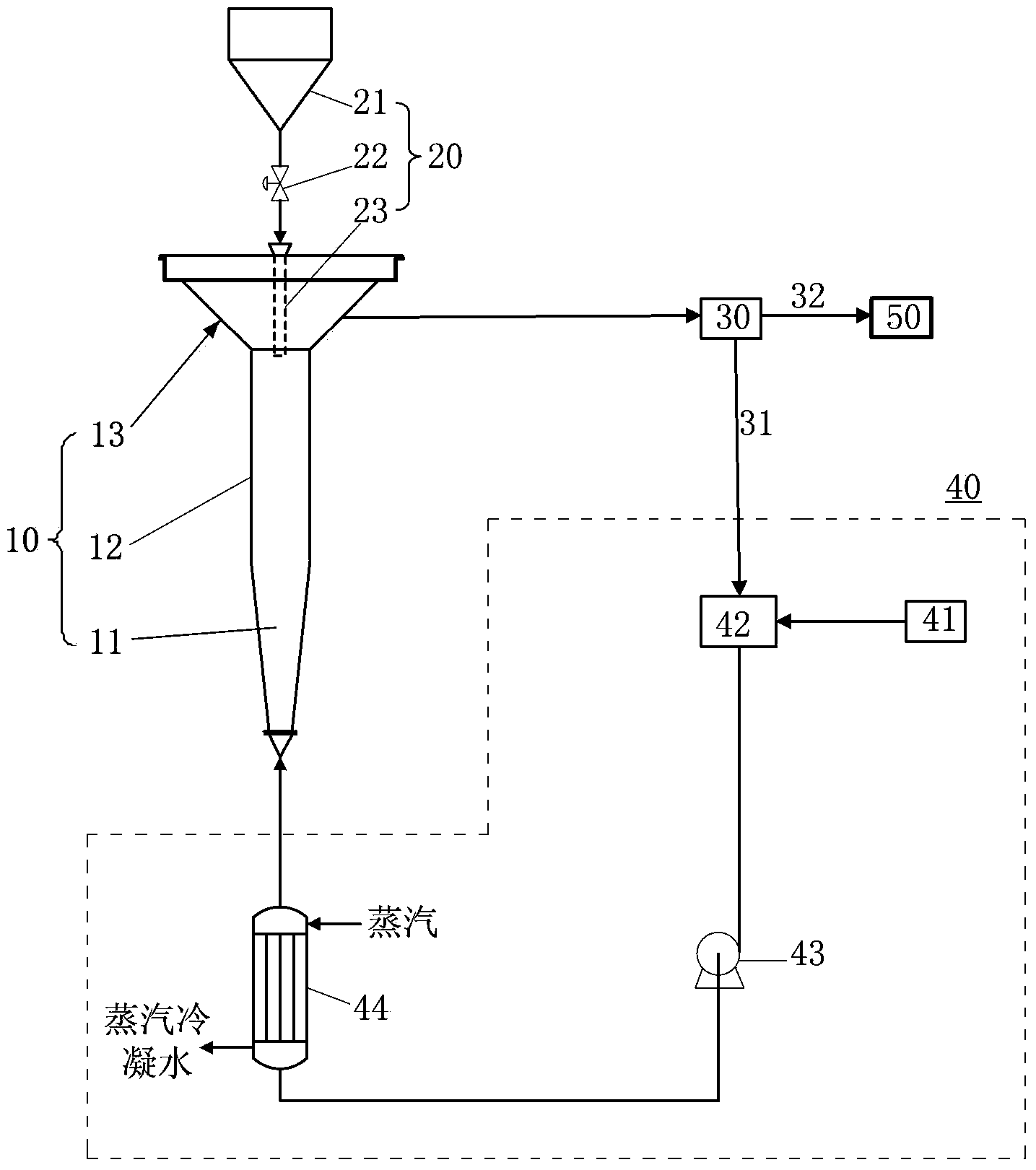

Method used

Image

Examples

example 1

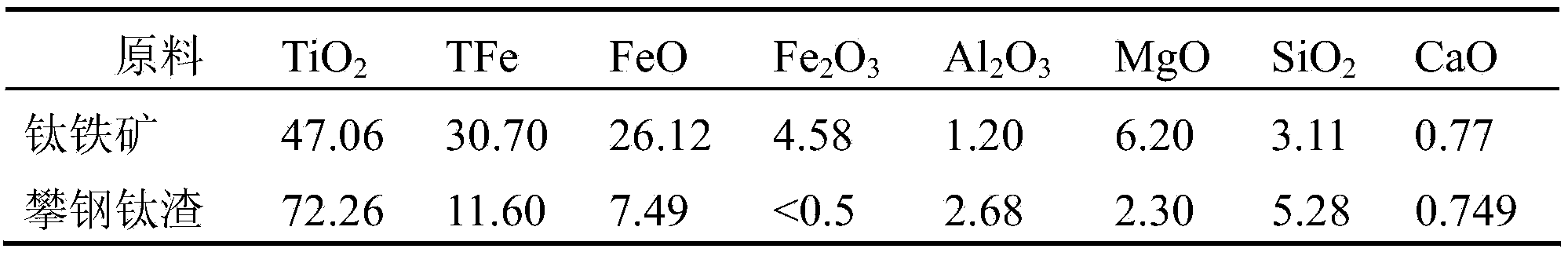

[0041] In the acid distribution tank, according to 20m 3 Hydrochloric acid, mixed with 128m 3 The proportion of water is prepared to make an acid concentration of 5% hydrochloric acid solution, pump the prepared acid into the circulation tank, use the circulation pump to pump the acid solution into the fluidized reactor, and use it when the acid solution enters the fluidized reactor Graphite heat exchanger is heated, and the steam flow rate is controlled to heat the acid solution to 80°C; by controlling the opening of the discharge valve under the silo, the feeding amount of titanium concentrate is controlled to be 1.5t / h, and the titanium concentrate is directly added to the fluidization reaction In the reaction section of the reactor, the particle size of the titanium concentrate is -325 mesh, and the flow rate of the acid solution is controlled to be 10m by adjusting the outlet valve of the circulating pump. 3 / h, so that the titanium concentrate is in a fluidized state in...

example 2

[0043] In the acid distribution tank, according to 20m 3 Hydrochloric acid, add 15m 3 The proportion of water is prepared to make an acid concentration of 22% hydrochloric acid solution, pump the prepared acid into the circulation tank, use the circulation pump to pump the acid solution into the fluidized reactor, and use it when the acid solution enters the fluidized reactor Graphite heat exchanger is heated, and the steam flow rate is controlled to heat the acid solution to 80°C; by controlling the opening of the discharge valve under the silo, the feeding amount of titanium concentrate is controlled to be 1.5t / h, and the titanium concentrate is directly added to the fluidization reaction In the reaction section of the reactor, the particle size of the titanium concentrate is -325 mesh, and the flow rate of the acid solution is controlled to 12m by adjusting the outlet valve of the pump. 3 / h, so that the titanium concentrate is in a fluidized state in the fluidized reactor...

example 3

[0045] In the acid distribution tank, according to the 5m 3 Hydrochloric acid, mix into 30m 3 The proportion of regenerated hydrochloric acid is prepared into a hydrochloric acid solution with an acid concentration of 23%, and the prepared acid is pumped into the circulation tank, and the acid solution is pumped into the fluidized reactor using a circulation pump. During the process of the acid solution entering the fluidized reactor Use a graphite heat exchanger to heat, control the steam flow to heat the acid solution to 70°C; by controlling the opening of the discharge valve under the silo, control the feeding amount of the titanium concentrate to 1.5t / h, and directly add the titanium concentrate to the fluidization In the reaction section of the reactor, the particle size of the titanium concentrate is -325 mesh, and the flow rate of the acid solution is controlled to be 12m by adjusting the outlet valve of the pump. 3 / h, so that the titanium concentrate is in a fluidize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com