Tiny gas sensor of laminated structure and preparation method of micro-gas sensor

A technology of gas sensor and laminated structure, applied in the direction of microstructure technology, microstructure device, manufacturing microstructure device, etc., can solve the problems such as inability to control separately, reuse of platinum wire resistance elements, etc., to improve the electric-heating efficiency, Effect of reduced heating power consumption and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

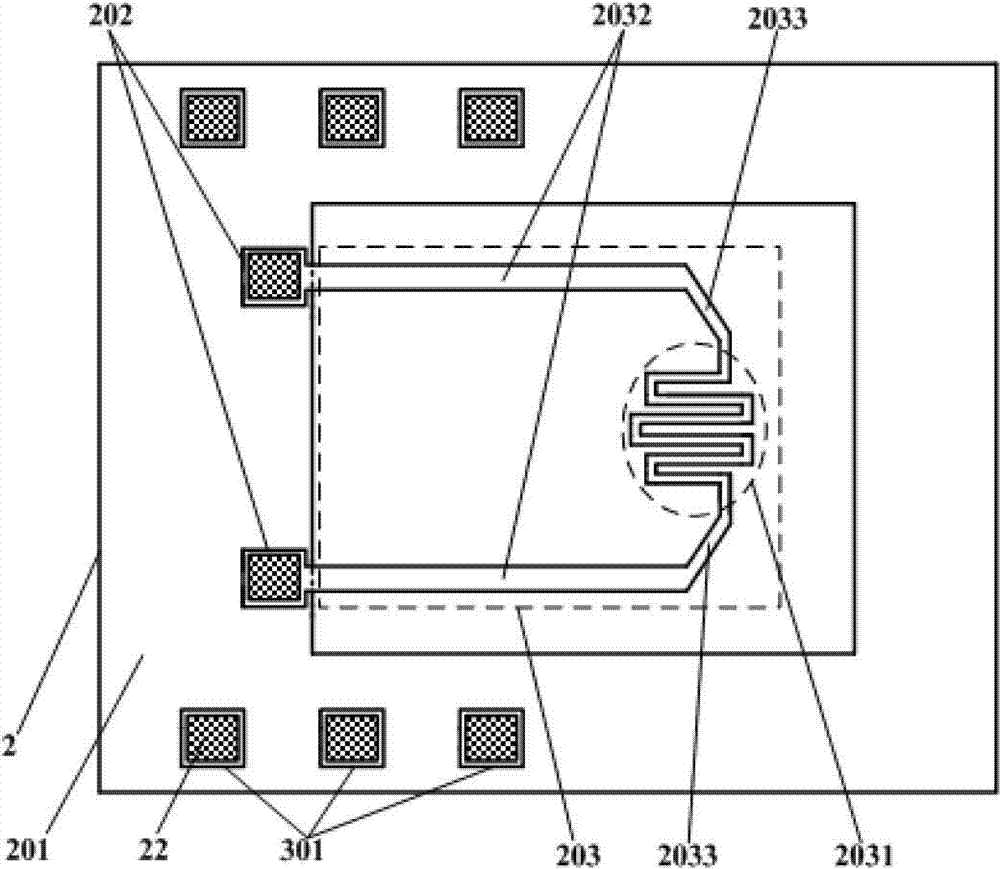

[0035] Embodiment 1: The microgas sensor of this laminated structure comprises figure 1 , figure 2 , image 3 , Image 6 , Figure 7 The single-chip gas microreactor 1 and the single-chip temperature detector 2 shown;

[0036] The monolithic gas microreactor 1 includes: a silicon frame support 101, a heating element 103, two fixed ends 102, two bonding-fixed ends 1021, multiple electrode lead-out ends 104, and multiple bonding support ends 301 , metal bumps 400 and catalyst carrier 105; the silicon frame support 101 includes a silicon substrate 11 and a buried layer of silicon oxide 12, such as Figure 4 As shown; the fixed end 102, the bonding-fixed end 1021, and the bonding support end 301 are all independently arranged on the buried silicon oxide 12 of the silicon frame support 101; the fixed end 102 includes a supporting silicon layer 21, a set The silicon oxide layer 23 outside the supporting silicon layer 21, the metal layer 22 arranged on the silicon oxide layer 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com