Automatic case unpacking machine

An unpacking machine and automatic technology, applied in the field of mechanical automation, can solve problems such as complex structure and inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

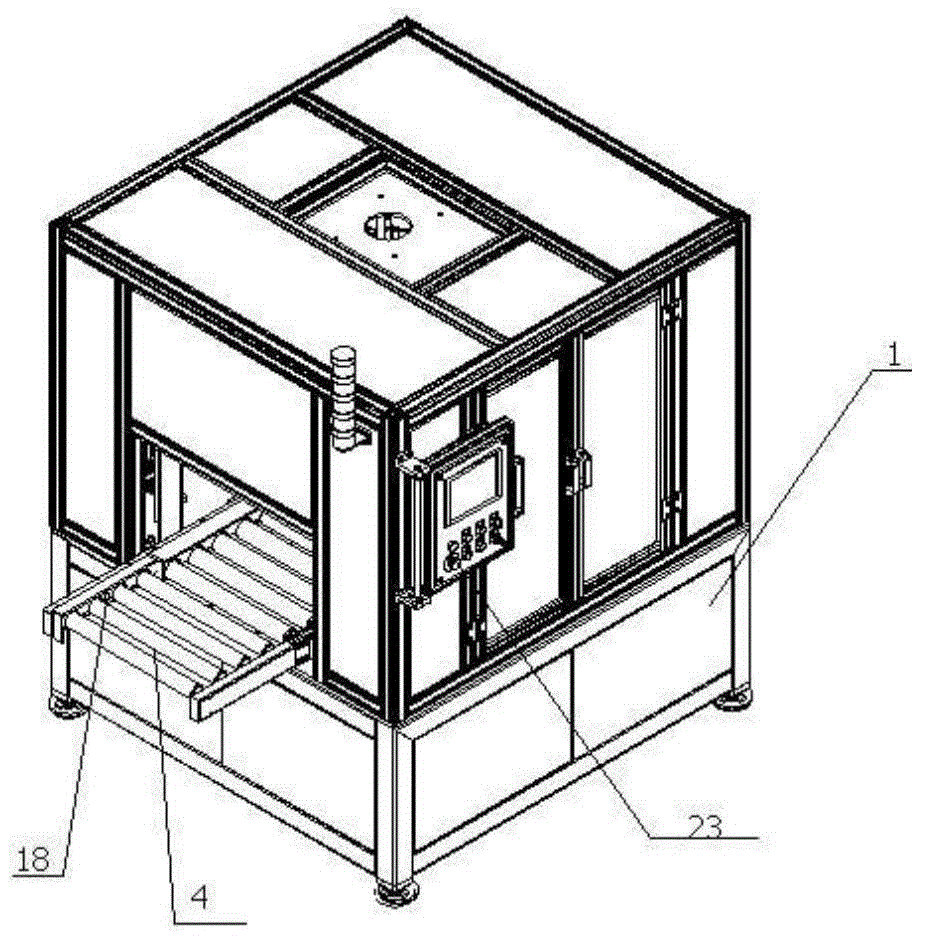

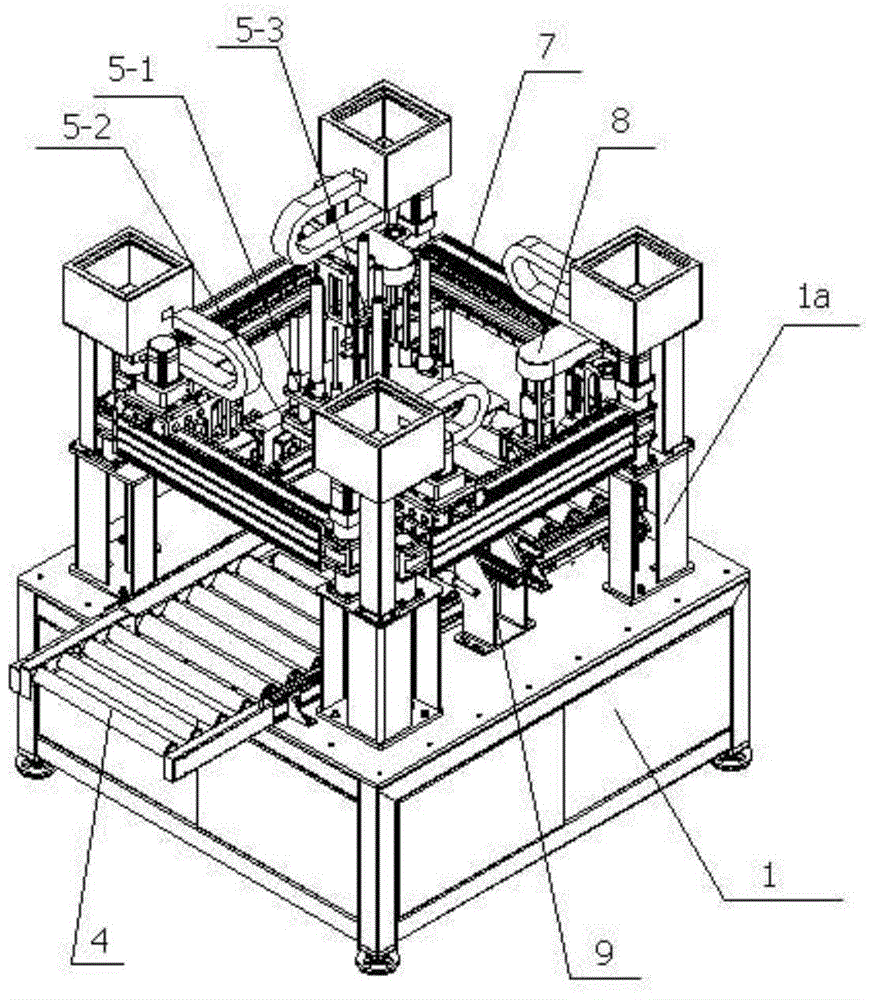

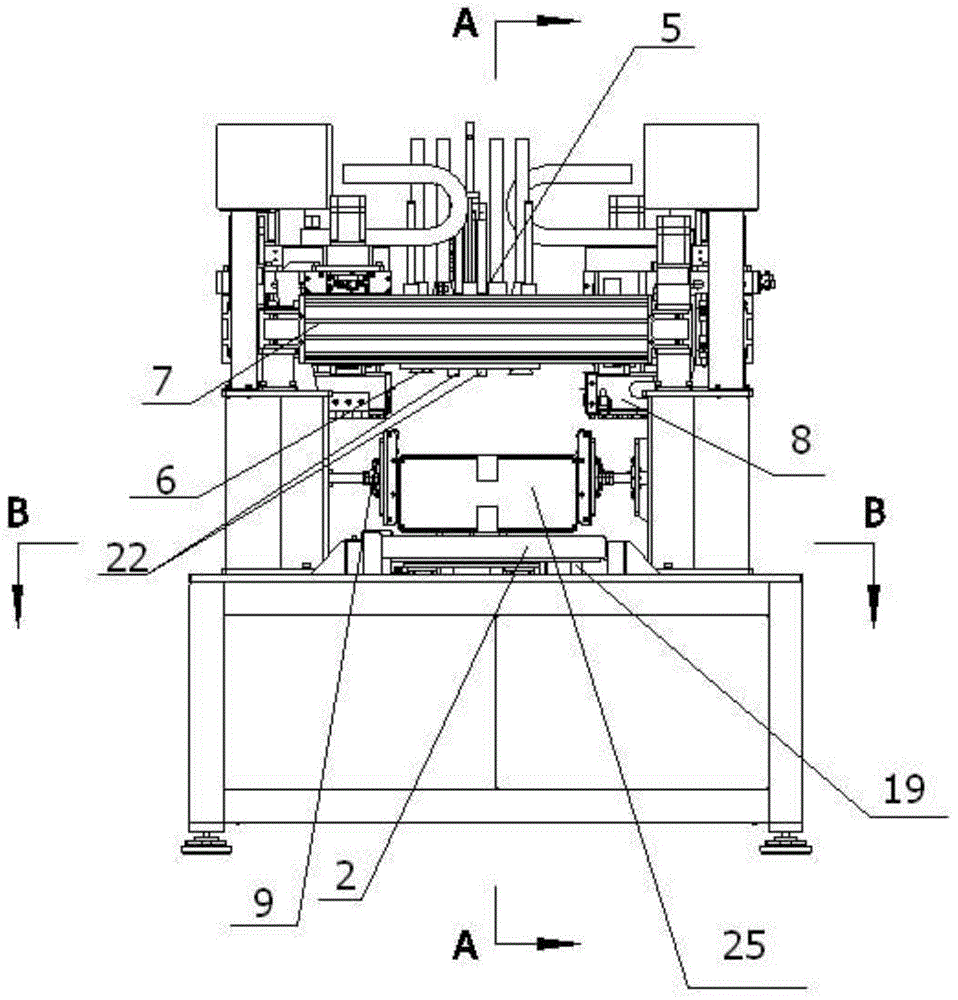

[0047] Such as Figure 1-23 As shown, the automatic unpacking machine of the present invention is mainly composed of a frame 1, a lifting belt mechanism 2, a stopper 3, a conveying system 4, an upper positioning mechanism 5, a vacuum suction cup 6, a linear motion module 7, a cutting head 8, a side Clamping device 9, AC servo servo motor 10, module reducer 11, module slide plate 12, module driving pulley 13, module driven pulley 14, module belt 15, slider 16, front machine Frame position sensor 17, rear frame position sensor 18, jacking belt mechanism sensor 19, stopper sensor 20, side pressure clamping device sensor 21, upper positioning mechanism sensor 22, control box 23, set control unit 24, carton 25, etc. components.

[0048] Described frame 1 comprises lower box body and is located at the cover body on lower box top plate, the front side opening of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com