Manufacturing method for asymmetric ripple pressure transmission assembly

A manufacturing method and asymmetric technology, applied in the direction of elastic deformation meter type fluid pressure measurement, etc., can solve the problems of insufficient response range of the sensor, change of sensor output, inability to output full scale, etc. The effect of reducing the force and ensuring the displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

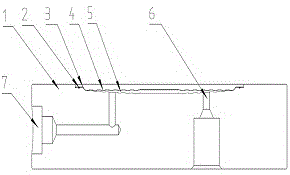

[0007] Corrugated diaphragm forming. The outer circle diameter is 66mm, the wave diameter is 60mm, and the diaphragm thickness is 0.08mm. The molding pressure is 35MPa±100KPa, and the holding time is 30 seconds.

[0008] The base is processed, and the corrugation profile of the spherical crown base is less than 0.008mm.

[0009] The corrugated diaphragm and the base are precisely positioned and laser-welded to form a pressure transmission component, and the weld seam is 1.5±0.5mm away from the corrugated position of the diaphragm. The coaxiality between the diaphragm and the base is less than 0.05mm.

[0010] Helium mass spectrometry leak detection, required leak rate 1X10 -9 Ensure welding air tightness.

[0011] For the pressure and displacement test, add a pressure of 2KPa to measure the change of the center displacement of the diaphragm on the component, and the center displacement reaches 0.7±0.1mm.

[0012] It should be emphasized that the above are only preferred e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com