A polishing method for polygonal or curved workpieces

A technology of curved workpiece and polygon, which is applied in the field of CNC polishing to achieve the effect of improving polishing accuracy, polishing efficiency and uniform polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

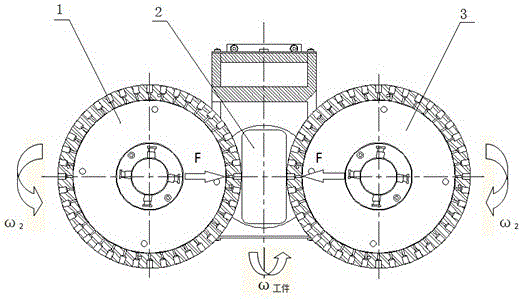

[0015] The method of the invention is a polishing method capable of processing polygonal or curved workpieces. As shown in the figure, when the polygonal or curved surface workpiece 2 is ω 工件 When rotating at a certain speed, the linear velocity of each polishing point changes due to the change of its radius R; at the same time, when the workpiece 2 pushes the polishing wheel 1 and polishing wheel 3 away, the polishing pressure F will also change, thus affecting the workpiece. The power of the rotating servo motor changes. The method of the present invention utilizes the polishing wheel driven by the air cylinder to act on the workpiece, utilizes the computer to collect the load signal of the servo motor that drives the workpiece to rotate, and controls the rotational speed of the workpiece through the numerical control program ω 工件 and the polishing pressure F of the polishing wheel on the workpiece; make the polishing pressure F and the workpiece speed ω 工件 respectively sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com