Preparation method of cationic polymer functionalized graphene-loaded platinum nanocomposite

A cationic polymer, platinum nanotechnology, used in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, nanotechnology, etc., can solve the difficulties and limitations of platinum nanoparticles, and achieve easy control of the reaction. , the effect of low cost and high load rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

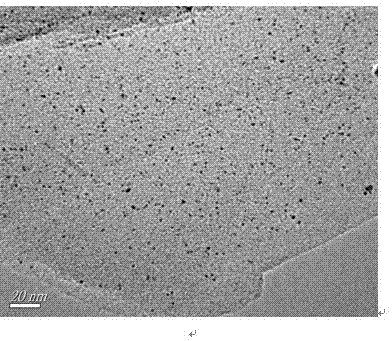

Image

Examples

example 1

[0020] (1) According to the mass ratio of dimethyl diallyl ammonium chloride, graphene and solvent is 0.5:15:1000, respectively weigh 5 mg of dimethyl diallyl ammonium chloride, 150 mg of graphene and volume ratio Be 10g of 1: 1 polyethylene glycol / ethylene glycol mixed solution, add dropwise polyethylene glycol / ethylene glycol mixed solution in dimethyl diallyl ammonium chloride and graphene, mix under ultrasonic again 0.5 h to mix evenly, then the mixture was stirred at room temperature for 24 h, then suction filtered, washed with twice distilled water, and finally vacuum-dried at 40°C for 4 h to obtain surface-functionalized graphene.

[0021] (2) Weigh chloroplatinic acid and place it in a polyethylene glycol / ethylene glycol mixed solution with a volume ratio of 1: 1 for ultrasonic dispersion. After dispersion, the proportion of chloroplatinic acid in the whole mixed solution: (polyethylene glycol) Ethylene glycol / ethylene glycol)=0.05:100 (g / mL) to obtain a yellow chlorop...

example 2

[0025](1) According to the mass ratio of dimethyl diallyl ammonium chloride, graphene and solvent is 1:15:1500, weigh 10 mg of dimethyl diallyl ammonium chloride, graphene 150 mg and volume ratio respectively Be 2: 1 polyethylene glycol / ethylene glycol mixed solution 15g, add dropwise polyethylene glycol / ethylene glycol mixed solution in dimethyl diallyl ammonium chloride and graphene, mix 0.5 under ultrasonic again h to mix evenly, then the mixture was stirred at room temperature for 24 h, then suction filtered, washed with twice distilled water, and finally vacuum-dried at 40°C for 6 h to obtain surface functionalized graphene.

[0026] (2) Weigh chloroplatinic acid and place it in a polyethylene glycol / ethylene glycol mixture with a volume ratio of 2: 1 for ultrasonic dispersion. After dispersion, the proportion of chloroplatinic acid in the whole mixed solution: (polyethylene glycol) Ethylene glycol / ethylene glycol)=0.06:100 (g / mL) to obtain a yellow chloroplatinic acid so...

example 3

[0030] (1) According to the mass ratio of dimethyl diallyl ammonium chloride, graphene and solvent is 1.5:16:1500, weigh 15 mg of dimethyl diallyl ammonium chloride, 160 mg of graphene and volume ratio respectively Be 3: 1 polyethylene glycol / ethylene glycol mixed solution 15g, add dropwise polyethylene glycol / ethylene glycol mixed solution in dimethyl diallyl ammonium chloride and graphene, mix 0.5 under ultrasonic again h to mix evenly, then the mixture was stirred at room temperature for 24 h, then suction filtered, washed with twice distilled water, and finally vacuum-dried at 40°C for 8 h to obtain surface-functionalized graphene.

[0031] (2) Weigh chloroplatinic acid and place it in a polyethylene glycol / ethylene glycol mixed solution with a volume ratio of 3: 1 for ultrasonic dispersion. After dispersion, the proportion of chloroplatinic acid in the whole mixed solution: (polyethylene glycol) Ethylene glycol / ethylene glycol)=0.07:100 (g / mL) to obtain a yellow chloropla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com