Preparation method based on amphoteric cellulose composite material

A technology of amphoteric cellulose and composite materials, applied in the direction of chemical instruments and methods, other chemical processes, etc., to achieve good adsorption performance, reasonable and effective utilization, green environmental protection and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

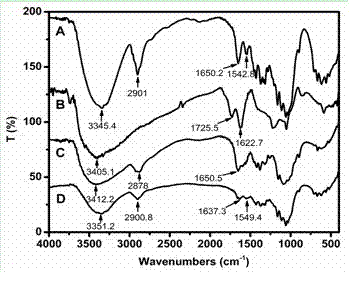

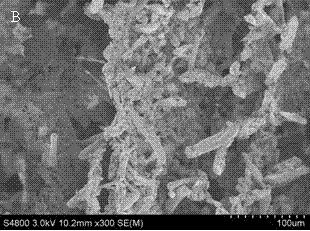

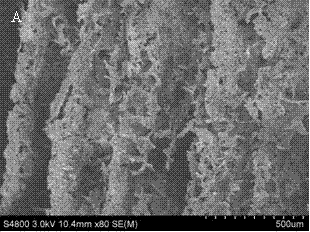

Image

Examples

Embodiment 1

[0034] Weigh 10g of cotton fiber, place in 400ml concentration of 2wt% sodium hydroxide solution, boil for 90min, transfer to 300ml concentration of 18wt% sodium hydroxide solution after cooling, let stand at room temperature for 120min, wash with deionized water for 5 Second, dry alkaline cotton fibers.

[0035] Take 5.0g of basic cotton fiber and place it in 300ml of acetone, add 5ml of 30wt% sodium hydroxide solution and 9g of 3-chloro-2-hydroxypropyltrimethylammonium chloride dropwise under stirring, and react in a water bath at 45°C for 3h Finally, adjust the pH value of the product to neutral with dilute hydrochloric acid, filter with suction, wash with methanol and absolute ethanol in sequence, and dry to constant weight to obtain quaternized cotton fiber.

[0036] Add 5.0g of quaternized cotton fiber and 400ml of deionized water into a three-necked flask, protect it with nitrogen, stir at 30°C for 15min, add 10g of cerium ammonium nitrate, react for 25min, and then add...

Embodiment 2

[0040] Weigh 10g of microcrystalline cellulose, place in 250ml of 0.5wt% sodium hydroxide solution, boil for 60min, transfer to 200ml of 10wt% sodium hydroxide solution after cooling, let it stand at room temperature for 120min, deionize Washed with water for 6 times and dried to obtain alkaline microcrystalline cellulose.

[0041] Take 8.0g of alkaline microcrystalline cellulose and place it in 200ml of acetone, add 8ml of 10wt% sodium hydroxide solution and 16g of 3-chloro-2-hydroxypropyltrimethylammonium chloride dropwise under stirring, and place in a water bath at 45°C After reacting for 3 hours, adjust the pH value of the product to neutral with dilute hydrochloric acid, filter with suction, wash with methanol and absolute ethanol in sequence, and dry to constant weight to obtain quaternized microcrystalline cellulose.

[0042] Add 5.0g of quaternized microcrystalline cellulose and 200ml of deionized water into a three-necked flask, protect it with nitrogen, stir at 25°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com