Method for modifying nickel lithium manganese anode material for lithium ion batteries

A lithium-ion battery, lithium nickel manganese oxide technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of difficult to uniform and complete coating of materials, affecting the electronic conductivity of materials, complex processes, etc., and achieve electrochemical performance. Excellent, high electronic conductivity, high conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

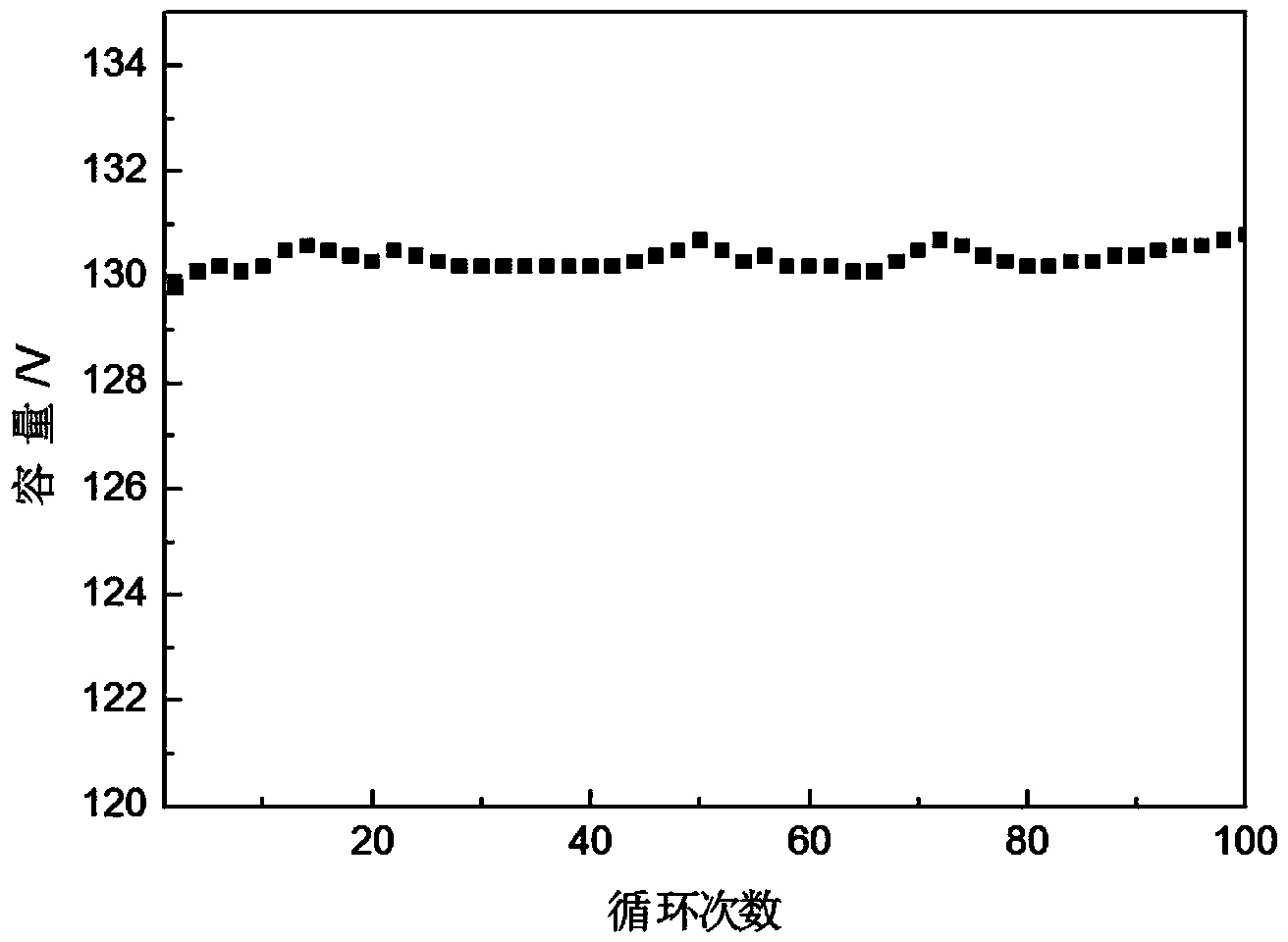

[0016] Example 1: Add 10g of lithium nickel manganese oxide and 0.015mol of cetyltrimethylammonium bromide into water and ultrasonically disperse for 10min, then add 0.015mol of ammonium persulfate and ultrasonically for 10min, then add 150ml dropwise with a concentration of 0.1mol / L pyrrole ethanol solution, after the dropwise addition, continue to sonicate for 5min, static aging for 1h, suction filtration, washing, and drying at 80°C to obtain a lithium nickel manganese oxide composite cathode material with a polypyrrole coating amount of 1%. The 1C initial discharge capacity of its button battery is 129.8mAh / g ( figure 1 ), the capacity retention rate of 100 cycles is 100.7% ( figure 2 ).

Embodiment 2

[0017] Example 2: Add 10g of lithium nickel manganese oxide and 0.068mol of sodium dodecylbenzenesulfonate into water and ultrasonically disperse for 15min, then add 0.045mol of ferric chloride and ultrasonically 10min, then add 150ml dropwise at a concentration of 0.3mol / L of pyrrole ethanol solution, continue ultrasonication for 10min after the dropwise addition, static aging for 1.5h, suction filtration, washing, and drying at 90°C to obtain a lithium nickel manganese oxide composite positive electrode material with a polypyrrole coating amount of 3%. The 1C initial discharge capacity of its button battery is 131mAh / g, and the capacity retention rate after 100 cycles is 99.8%.

Embodiment 3

[0018] Example 3: Add 10g of lithium nickel manganese oxide and 0.15mol of sodium lauryl sulfate into water and ultrasonically disperse for 20min, then add 0.075mol of ferric chloride and ultrasonically for 15min, then add 150ml dropwise at a concentration of 0.5mol / L Pyrrole ethanol solution, continue ultrasonication for 15min after the dropwise addition, static aging for 3h, suction filtration, washing, and drying at 100°C to obtain a lithium nickel manganese oxide composite positive electrode material with a polypyrrole coating amount of 5%. The 1C initial discharge capacity of its button battery is 129.5mAh / g, and the capacity retention rate after 100 cycles is 100.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com