Micro LED integrated array device and preparation method

An integrated array and miniature technology, which is applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of being unable to meet the needs, difficult to make the pixel size small, resolution limitation, etc., and achieve simple structure, fast response, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

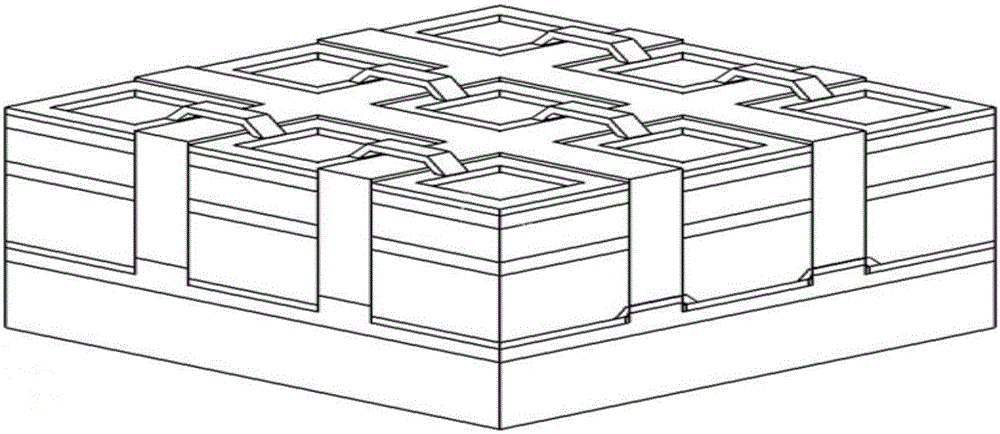

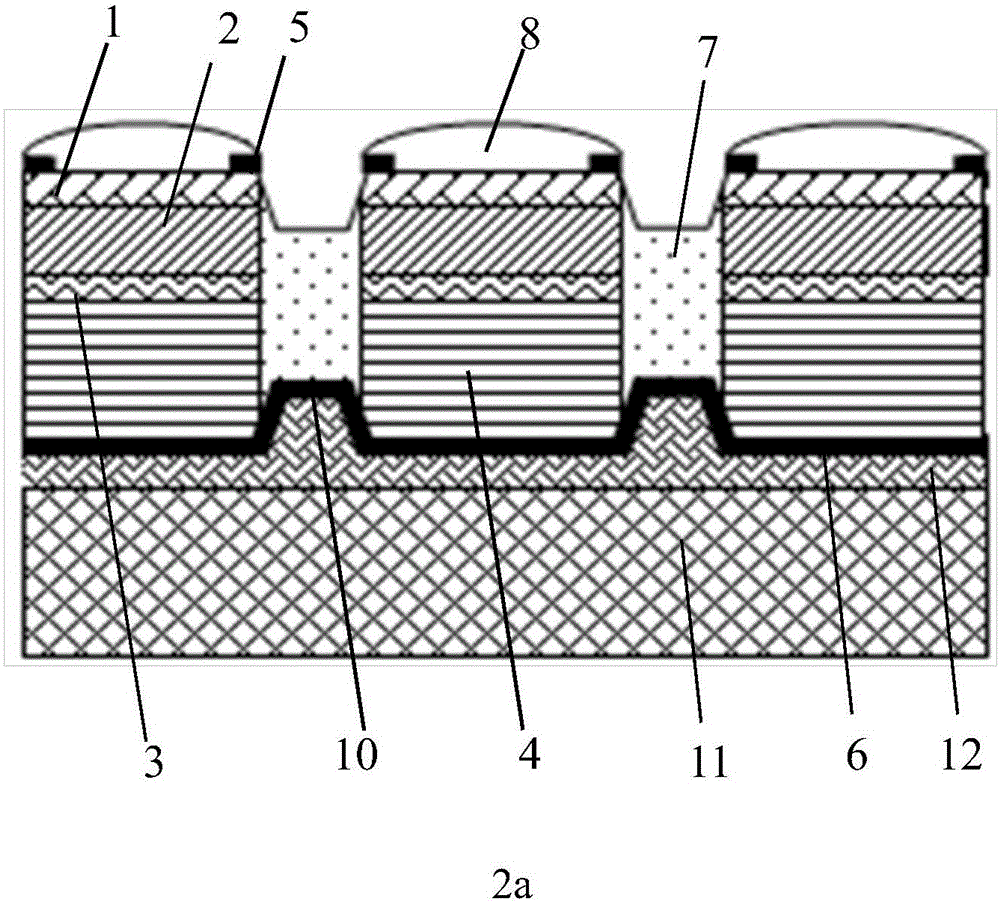

[0031] Specific implementation mode 1. Combination Figure 1 to Figure 8 Description of this embodiment, the micro LED integrated array device includes: a light-transmitting layer 1, a light-emitting layer 2, a reflective layer 3, a substrate 4, an upper electrode 5, an upper electrode lead 9, a lower electrode 6, a lower electrode lead 10, and an aperture 7. Microlens 8 and substrate 11 . The light-transmitting layer 1, the light-emitting layer 2, the reflective layer 3, the substrate 4 and the micro-lens 8 form an LED light-emitting unit. The upper surface of the reflective layer 3 is the luminous layer 2 , the light-transmissive layer 1 and the microlens 8 in sequence, and the lower surface of the reflective layer 3 is the substrate 4 . The LED light-emitting units are uniformly arranged to form a light-emitting unit array. A diaphragm 7 is located between the light emitting units, and the diaphragm 7 connects each light emitting unit in sequence and realizes the isolatio...

specific Embodiment approach 2

[0034] Specific embodiment two, combine Figure 9 Describe this embodiment, this embodiment is the preparation method of the micro-LED integrated array device described in the first embodiment; this embodiment adopts a bottom-up manufacturing method, that is, first fabricate the back structure, and then protect the back structure , to prepare the frontal structure. During the fabrication process, flexible electrodes are fabricated by filling flexible materials and photoetching special topography.

[0035] A. Thinning of the back of the light-emitting chip:

[0036] a) The host material used in the present invention is a light-emitting chip, and the light-emitting chip used is composed of a light-transmitting layer, a light-emitting layer, a reflective layer and a substrate, such as Figure 9 as shown in a.

[0037] b) Cleaning the light-emitting chip. Then prepare a layer of protective film on the upper surface of the light-emitting chip, that is, the upper surface of the li...

specific Embodiment approach 3

[0054] Specific Embodiment 3. This embodiment is the preparation method of the micro-LED integrated array device described in Specific Embodiment 2, which is realized by the following steps:

[0055] A. Thinning of the back of the light-emitting chip:

[0056] a) The light-emitting chip described in this embodiment is an AlGaInP-LED epitaxial wafer, which is composed of a light-transmitting layer, a light-emitting layer, a reflective layer and a substrate, and the thickness of the light-emitting chip is 200 μm to 1000 μm. The lower surface of the light-emitting chip is thinned and polished by mechanical thinning and polishing or chemical thinning and polishing or a combination of mechanical and chemical methods, and the light-emitting chip after thinning is 20-300 μm.

[0057] b) The material of the protective film prepared on the upper surface of the light-emitting chip is silicon dioxide or silicon nitride or a composite film composed of silicon dioxide and silicon nitride o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com