Control transformer

A technology of transformers and magnetic cores, applied in the field of transformers, can solve the problems of increasing the perimeter and total length of copper wire turns, increasing heat consumption of DC resistance, and unbalanced magnetic field distribution, so as to improve electromagnetic conversion efficiency and shorten the cycle time. The effect of long and saving copper consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

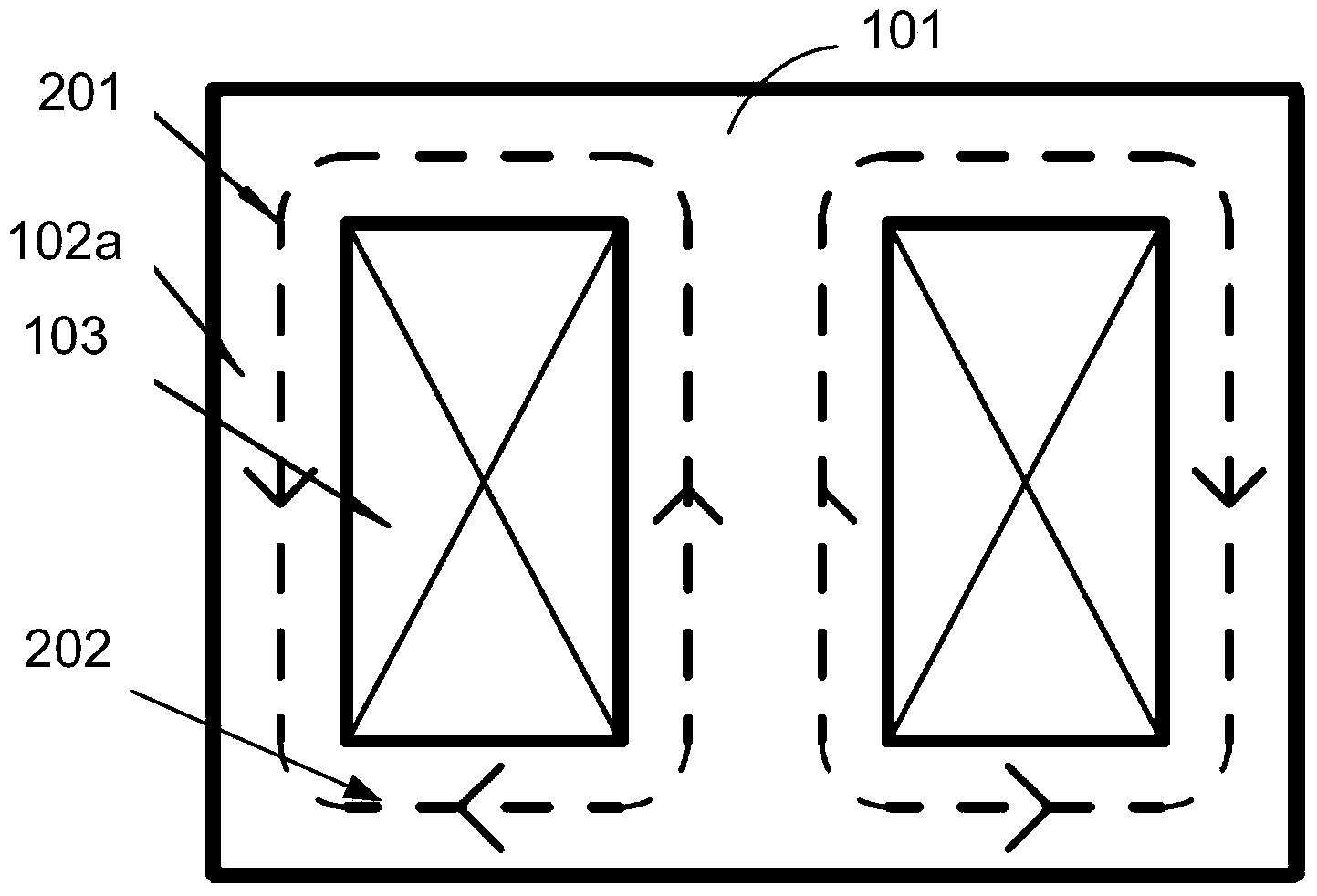

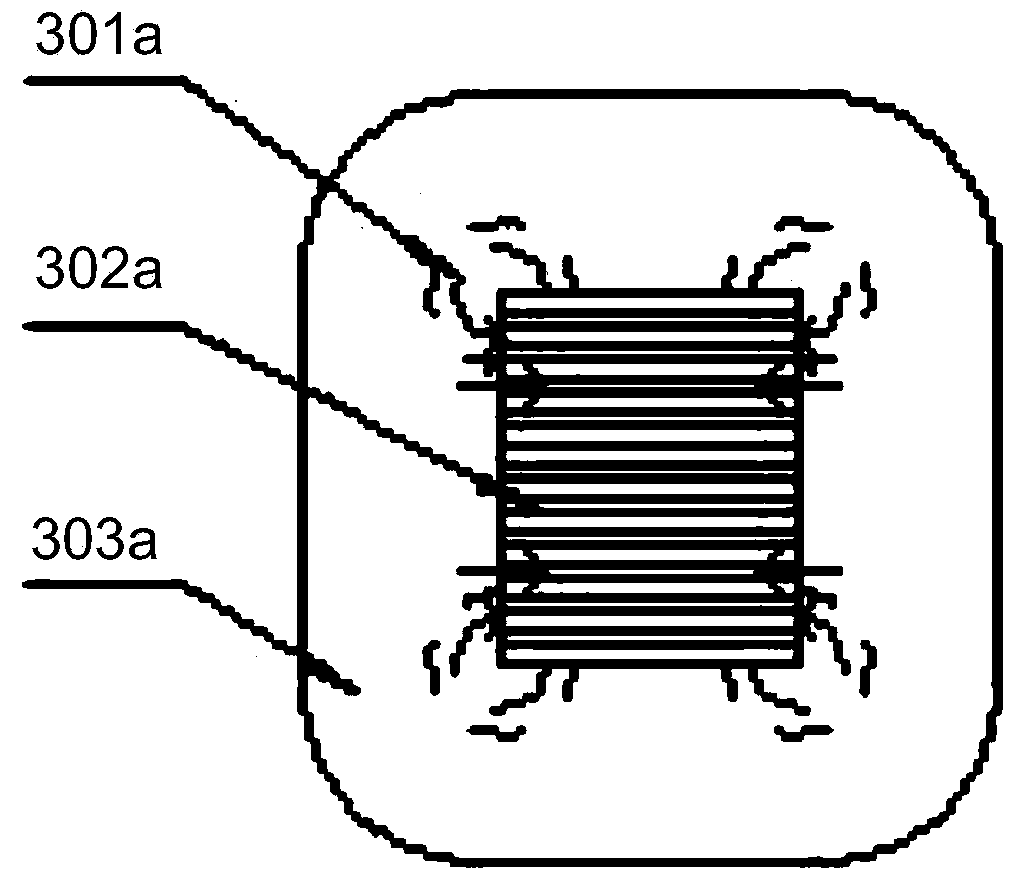

[0022] According to Faraday's law of electromagnetic induction V=-N(dФ / dt)=-NBAω, the invented control transformer is explained. In the formula, V is the generated voltage, N is the number of turns of the coil, dФ / dt is the changing magnetic field, B is the strength of the magnetic field, and A is the cross-sectional area of the magnetic core, so that the voltage V and the magnetic field strength B are the magnetic core cross-sectional area A The product is proportional to the voltage and the number of turns of the coil. In the case of a set primary or secondary voltage, the product of the number of turns of the coil and the cross-sectional area of the magnetic core is a design constant. The greater the magnetic field strength, the The larger the generated voltage (or current), the larger the cross-sectional area of the magnetic core, the larger the generated voltage (or current), and the higher the electromagnetic conversion efficiency.

[0023] Embodiments of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com