A flexible and stretchable electronic label and its preparation method

A technology of an electronic label and a manufacturing method, applied in the field of radio frequency identification, achieves the effects of strong resistance to peeling and damage, simple and efficient manufacturing process, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

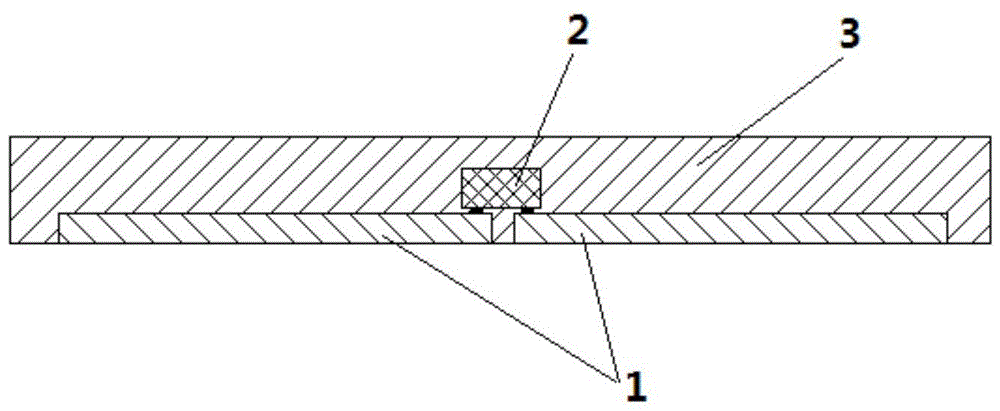

[0028] 1. Place a mask plate engraved with a hollow pattern of antenna lines on the glass substrate, spray the ethanol solution containing silver nanowires evenly on the surface of the mask plate with a spray gun, and remove the mask after the ethanol solution containing silver nanowires is completely dry plate, to obtain a metal nanoantenna 1 attached to a silver nanowire antenna circuit on the substrate; the circuit pattern of the metal nanowire antenna 1 is provided with a chip connection;

[0029] 2. Paste the chip 2 upside down on the chip connection of the metal nano-antenna 1, so that the chip contacts are electrically connected to the antenna;

[0030] 3. Pouring two-component addition-type silica gel (silica gel and crosslinking agent prepared at a weight ratio of 10:1) onto the substrate so that it completely covers the metal nanoantenna 1;

[0031] 4. Put the whole substrate into an oven and bake at 150°C for 20mins to completely cure the two-component addition-type...

Embodiment 2

[0035] 1. Place a mask plate engraved with a hollow pattern of antenna lines on the stainless steel substrate, spray the aqueous solution containing silver nanowires evenly onto the surface of the mask plate by casting method, and remove the mask after the aqueous solution containing silver nanowires is completely dry plate, to obtain a metal nanoantenna 1 attached to a silver nanowire antenna circuit on the substrate; the circuit pattern of the metal nanowire antenna 1 is provided with a chip connection;

[0036] 2. Paste the chip 2 upside down on the chip connection of the metal nano-antenna 1, so that the chip contacts are electrically connected to the antenna;

[0037] 3. Pouring one-component RTV silica gel onto the substrate so that it completely covers the metal nanoantenna 1;

[0038] 4. Put the whole substrate at room temperature for 12 hours, so that the vulcanized silica gel is completely cured to form a silica gel matrix 3;

[0039] 5. Remove the silicone substrat...

Embodiment 3

[0042] 1. Place a mask plate engraved with a hollow pattern of antenna lines on the glass substrate, spray the ethanol solution containing copper nanowires evenly on the surface of the mask plate with a spray gun, and remove the mask after the ethanol solution containing copper nanowires is completely dry plate, to obtain a metal nanoantenna 1 attached to a copper nanowire antenna circuit on the substrate; the circuit pattern of the metal nanowire antenna 1 is provided with a chip connection;

[0043] 2. Paste the chip 2 upside down on the chip connection of the metal nano-antenna 1, so that the chip contacts are electrically connected to the antenna;

[0044] 3. Pouring two-component condensation silica gel (silica gel and crosslinking agent prepared at a weight ratio of 5:1) onto the substrate so that it completely covers the metal nanoantenna 1;

[0045] 4. Put the substrate as a whole into an oven and bake at 120°C for 30mins to completely cure the two-component condensati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com