BOPP detachable and undetachable label and preparation process thereof

A preparation process and label technology, applied in the field of BOPP detachable and non-detachable labels and their preparation technology, can solve the problems of weak polarity, increase the difficulty of label production, low surface energy of BOPP, etc., achieve low cost, meet the needs of express logistics, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

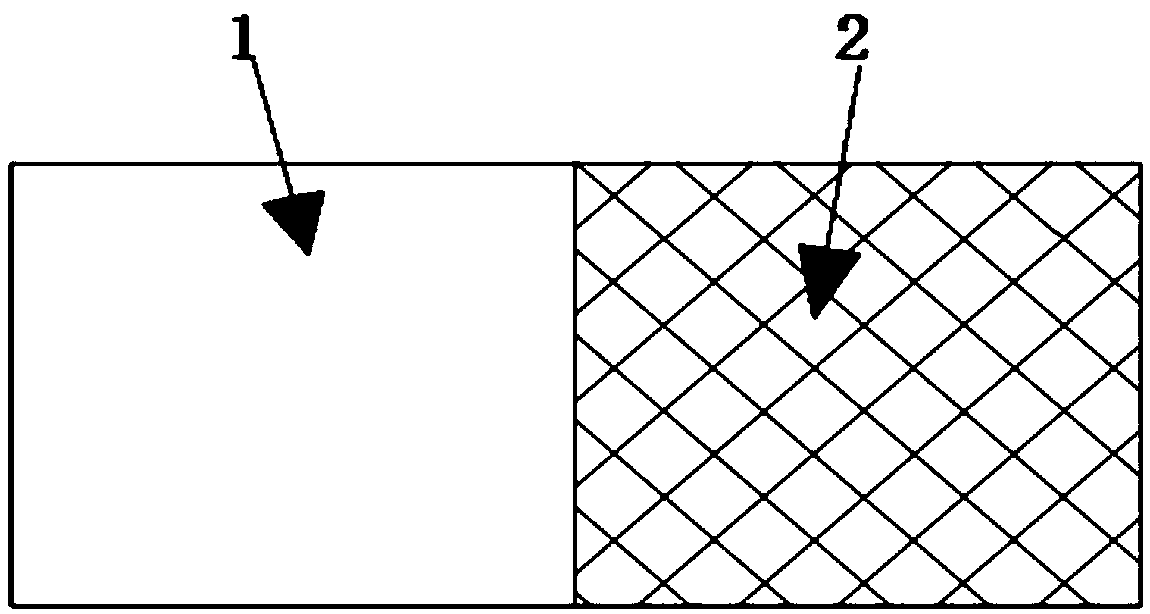

[0024] The BOPP detachable and non-detachable label of the present invention is obtained through the following preparation process:

[0025] (1) Through the silicon coating equipment, put on the glassine backing paper, according to 0.8g / m 2 Standard coating of solvent-free water-based silicone oil, solvent-free water-based silicone oil is coated on the smooth side of the glassine backing paper, and then completely dried by a 160°C bellows at a speed of 3m / s;

[0026] (2) Through the hot melt adhesive coating equipment, according to the paper threading requirements of the equipment design, put on the glassine backing paper coated with solvent-free water-based silicone oil, and coat 18g / m on the glassine backing paper coated with solvent-free water-based silicone oil 2 Hot-melt pressure-sensitive adhesive, and then compound BOPP on the surface of the hot-melt pressure-sensitive adhesive to make a semi-finished product;

[0027] (3) Through the printing equipment, according to t...

Embodiment 2

[0030] The BOPP detachable and non-detachable label of the present invention is obtained through the following preparation process:

[0031] (1) Through the silicon coating equipment, put on the glassine backing paper, according to 0.9g / m 2 Standard coating of solvent-free water-based silicone oil, solvent-free water-based silicone oil coated on the smooth surface of the glassine backing paper, and then completely dried by a 160°C bellows at a speed of 4m / s;

[0032] (2) Through the hot melt adhesive coating equipment, according to the paper threading requirements of the equipment design, put on the glassine backing paper coated with solvent-free water-based silicone oil, and coat 20g / m on the glassine backing paper coated with solvent-free water-based silicone oil 2 Hot-melt pressure-sensitive adhesive, and then compound BOPP on the surface of the hot-melt pressure-sensitive adhesive to make a semi-finished product;

[0033] (3) Through the printing equipment, the semi-finis...

Embodiment 3

[0036] The BOPP detachable and non-detachable label of the present invention is obtained through the following preparation process:

[0037] (1) Through the silicon coating equipment, put on the glassine backing paper, according to 1g / m 2 Standard coating of solvent-free water-based silicone oil, solvent-free water-based silicone oil coated on the smooth surface of the glassine backing paper, and then completely dried by a 160°C bellows at a speed of 4m / s;

[0038] (2) Through the hot melt adhesive coating equipment, according to the paper threading requirements of the equipment design, put on the glassine backing paper coated with solvent-free water-based silicone oil, and coat 22g / m on the glassine backing paper coated with solvent-free water-based silicone oil 2 Hot-melt pressure-sensitive adhesive, and then compound BOPP on the surface of the hot-melt pressure-sensitive adhesive to make a semi-finished product;

[0039] (3) Through the printing equipment, the semi-finishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com