Controller and control method based on FPGA (Field Programmable Gate Array) of scanning ionic conductivity microscope

A technology of scanning ion conductance and control method, which is applied in the controller and control field of scanning ion conductance microscope, can solve the problems of slow control, less consideration of system architecture and human-computer interaction, long experimental imaging time, etc., and achieve volume reduction , miniaturization, and increased application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

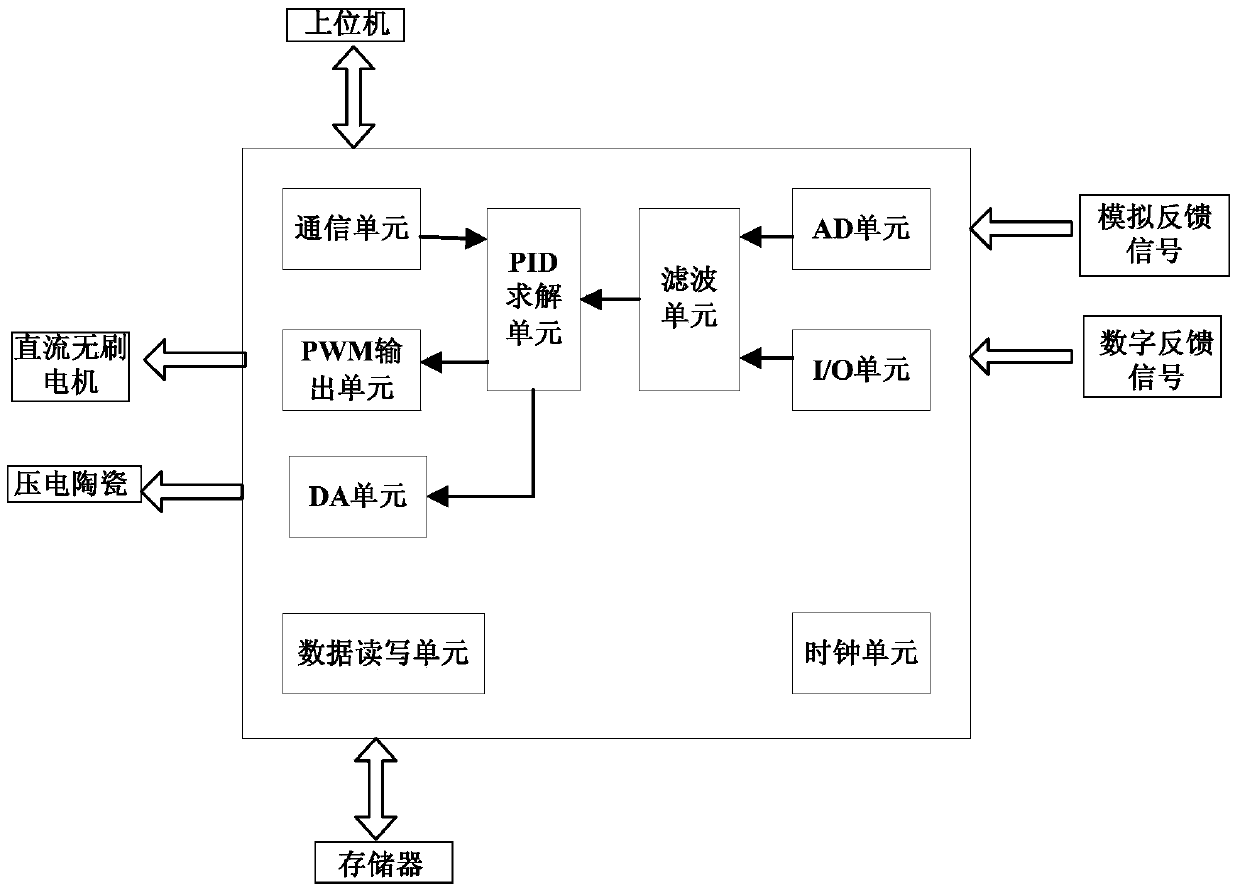

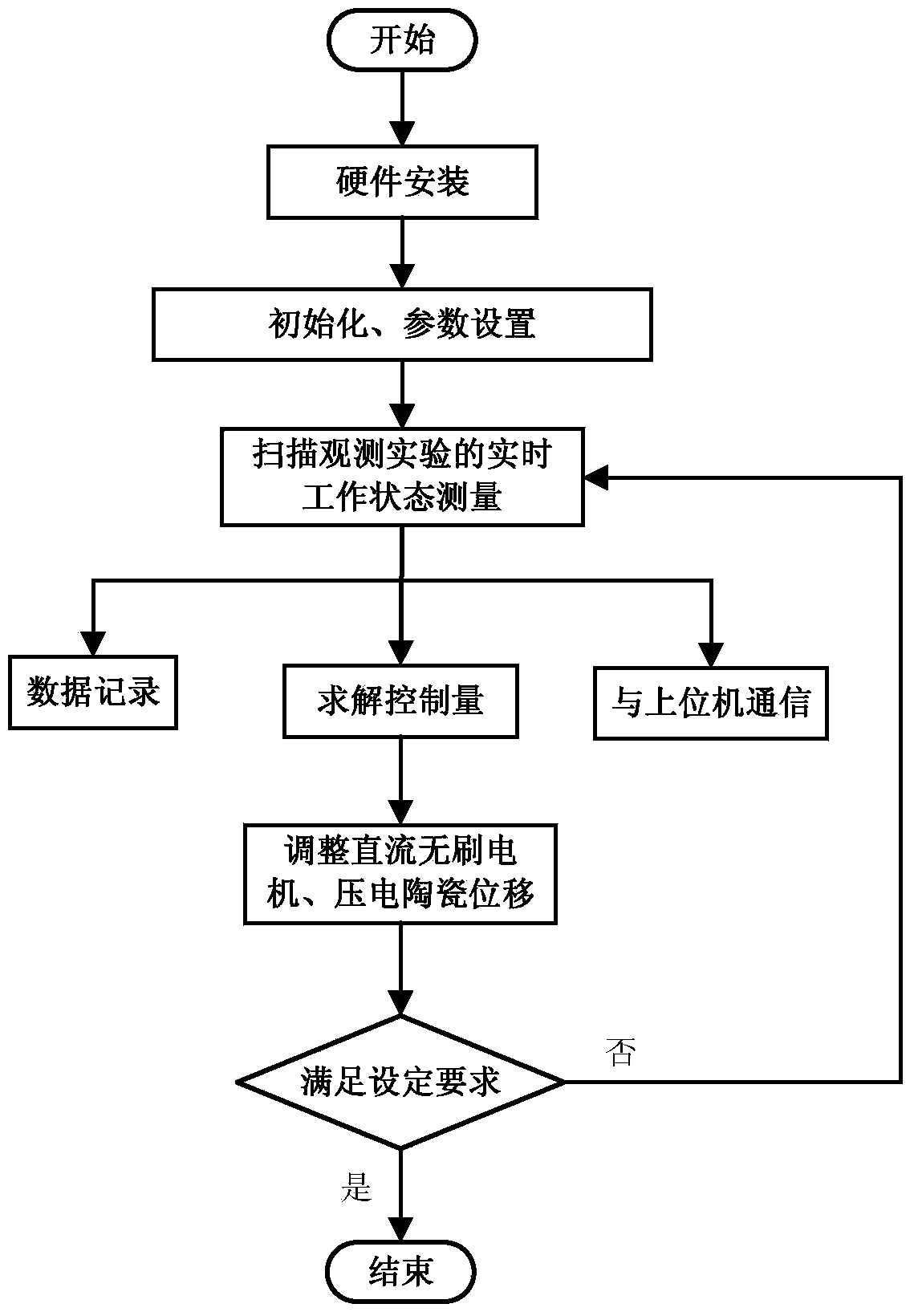

[0038] Such as figure 1 As shown, the controller of the FPGA-based scanning ion conductance microscope provided by the present invention is divided into 9 processing units that operate in parallel with each other: clock unit, I / O unit, communication unit, DA unit, AD unit, filter unit, data Read and write unit, PID solving unit, PWM output unit, where AD unit and I / O unit are signal acquisition units, PWM output unit and DA unit are output units. The communication unit communicates with the host computer through the peripheral communication interface to obtain the preset control target, and transmits the control target to the PID solving unit. At the same time, the human-computer interaction communication can be completed through the external keyboard, and the real-time work of the scanning observation experiment can be read out through the host computer. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com